Apparatus for coating a profile surface, and coating method thereof

a technology for profile surfaces and apparatuses, applied in the direction of coatings, pretreated surfaces, liquid spraying apparatuses, etc., can solve the problems of limited mass productivity, limited aesthetic properties, and weak feelings of people, and achieve the effect of preventing the splash preventing the scattering of metallic texture pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Preferred examples of the present invention are explained in detail below, with reference to the accompanying drawings.

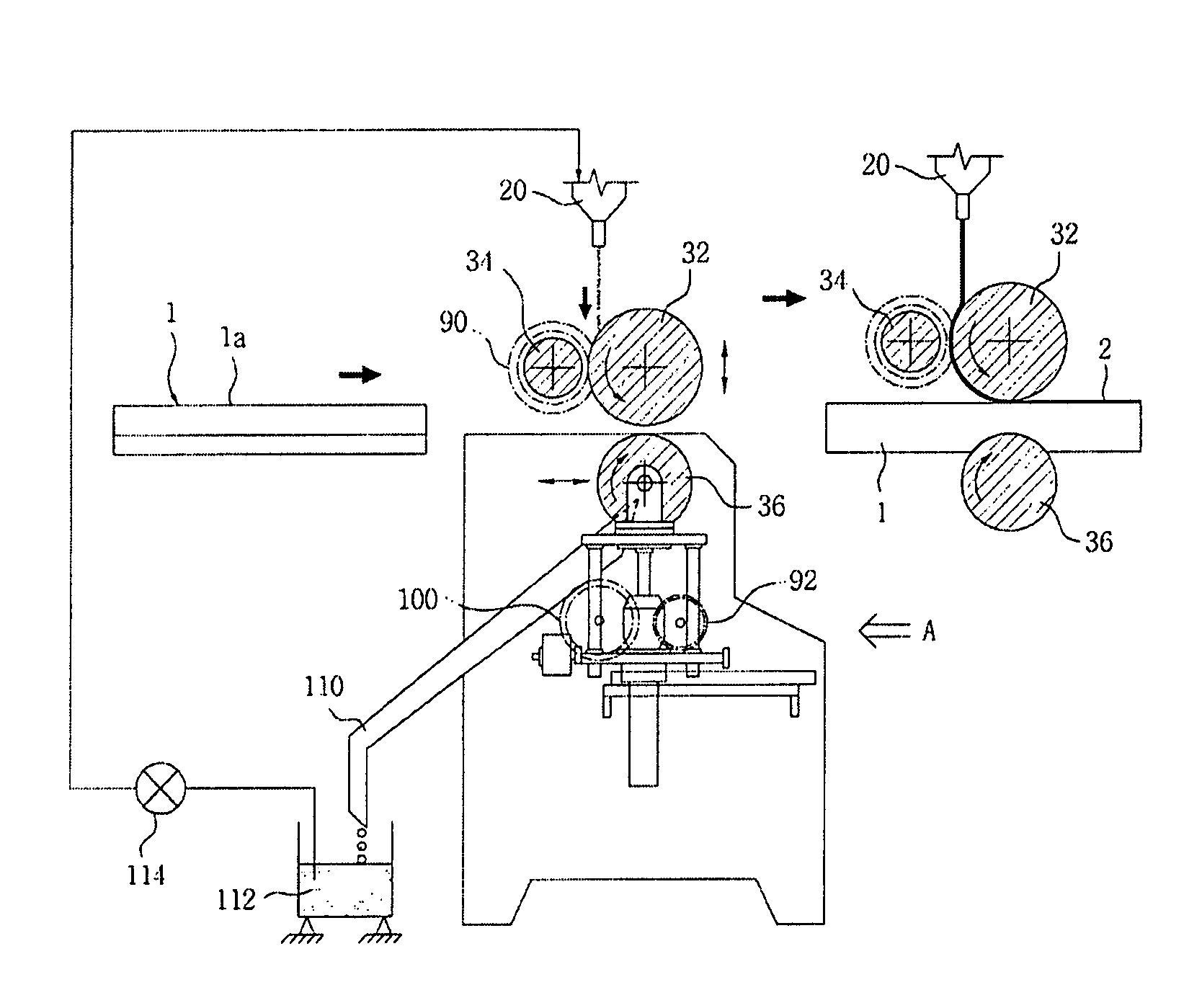

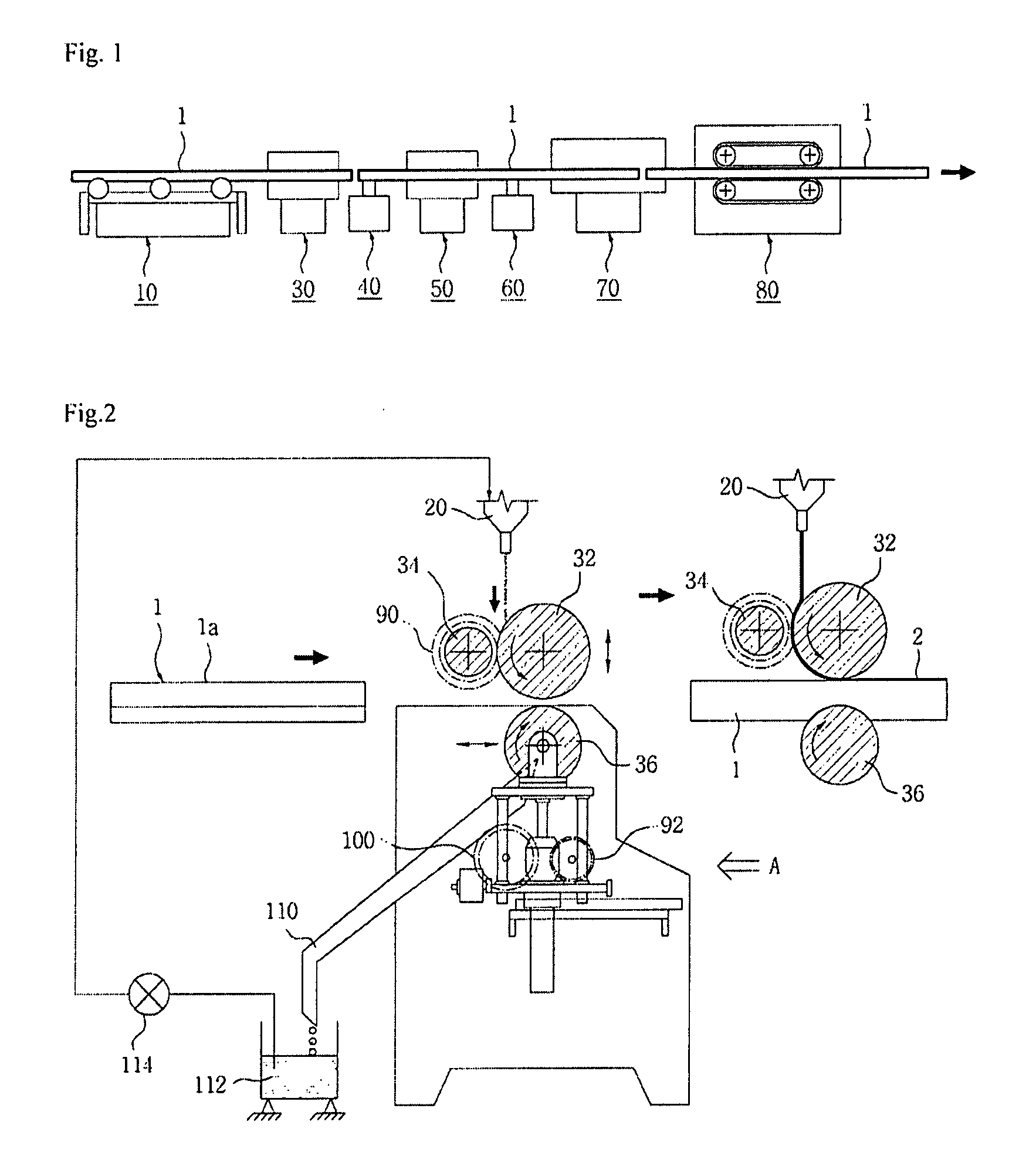

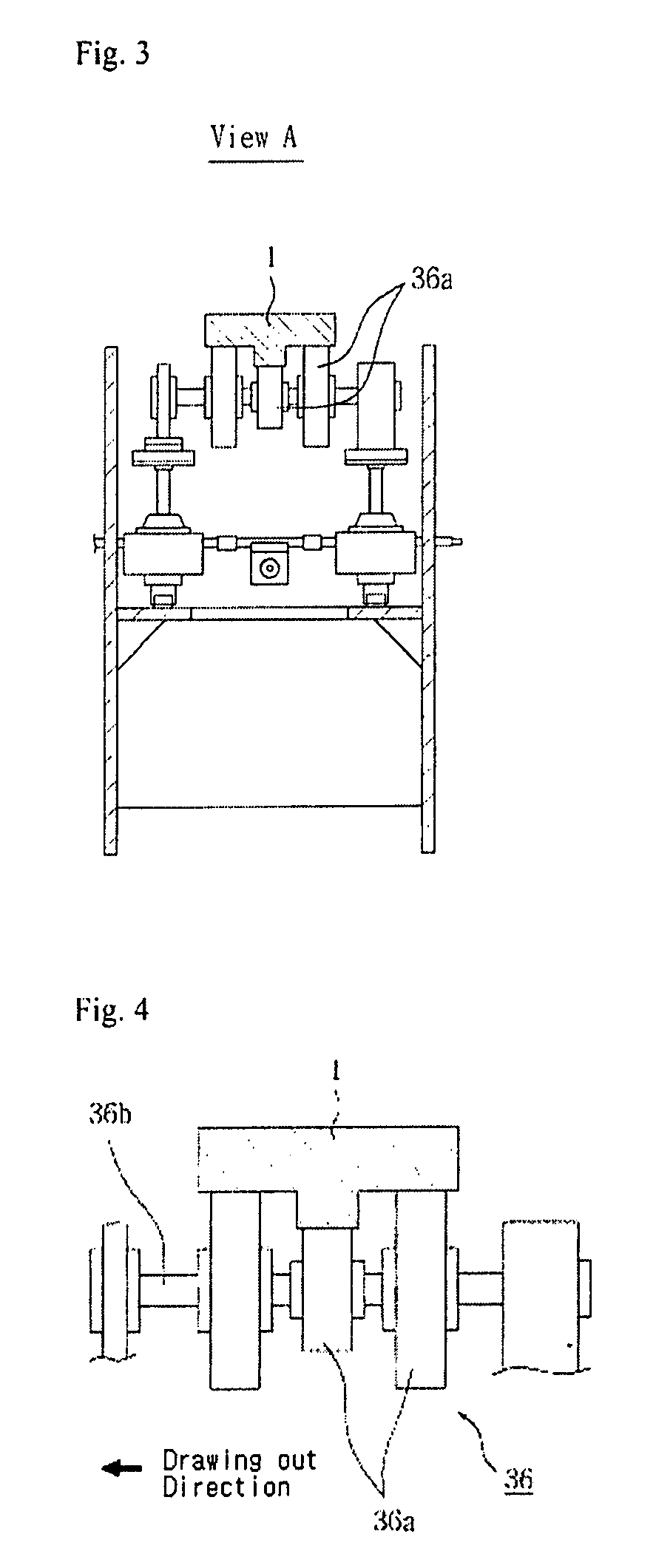

[0032]FIG. 1 is a view showing an entire structure of an apparatus for coating a profile, according to the present invention. FIG. 2 is a detail view of a roll coater in the apparatus for coating a profile, according to the present invention. FIG. 3 is a view of a roll coater viewed from “A” in FIG. 2. FIG. 4 is a view showing a structure of a back up roll in the apparatus for coating a profile, according to the present invention. FIG. 5 is a view of showing a state where a control roll for coating thickness is longitudinally transported. FIG. 6 is a view showing a state where height of a coating roll and a control roll for coating thickness is adjusted. FIG. 7 is a view showing a state where a back-up roll is longitudinally transported. FIG. 8 is a detail view of a spray coater in the apparatus for coating a profile, according to the present invention. FIG. 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| metallic | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com