Fresh product dispensing system

a technology of fresh products and dispensers, applied in the field of fresh product dispensers, can solve the problems of not being fresh, not being appealing, and being old, and achieve the effects of reducing shipping costs, preventing leakage and contamination, and losing potency, color, flavor and/or nutritional benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

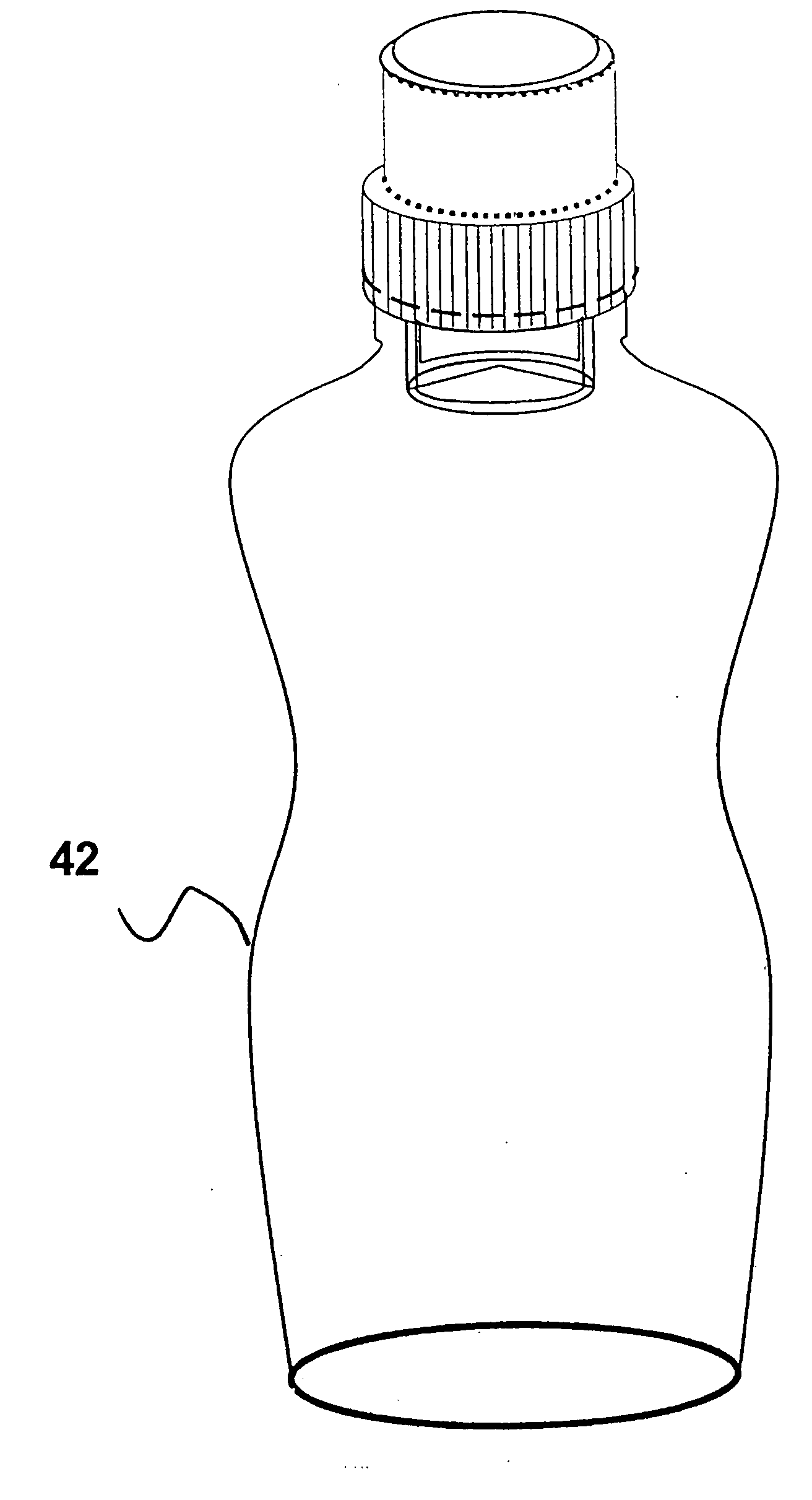

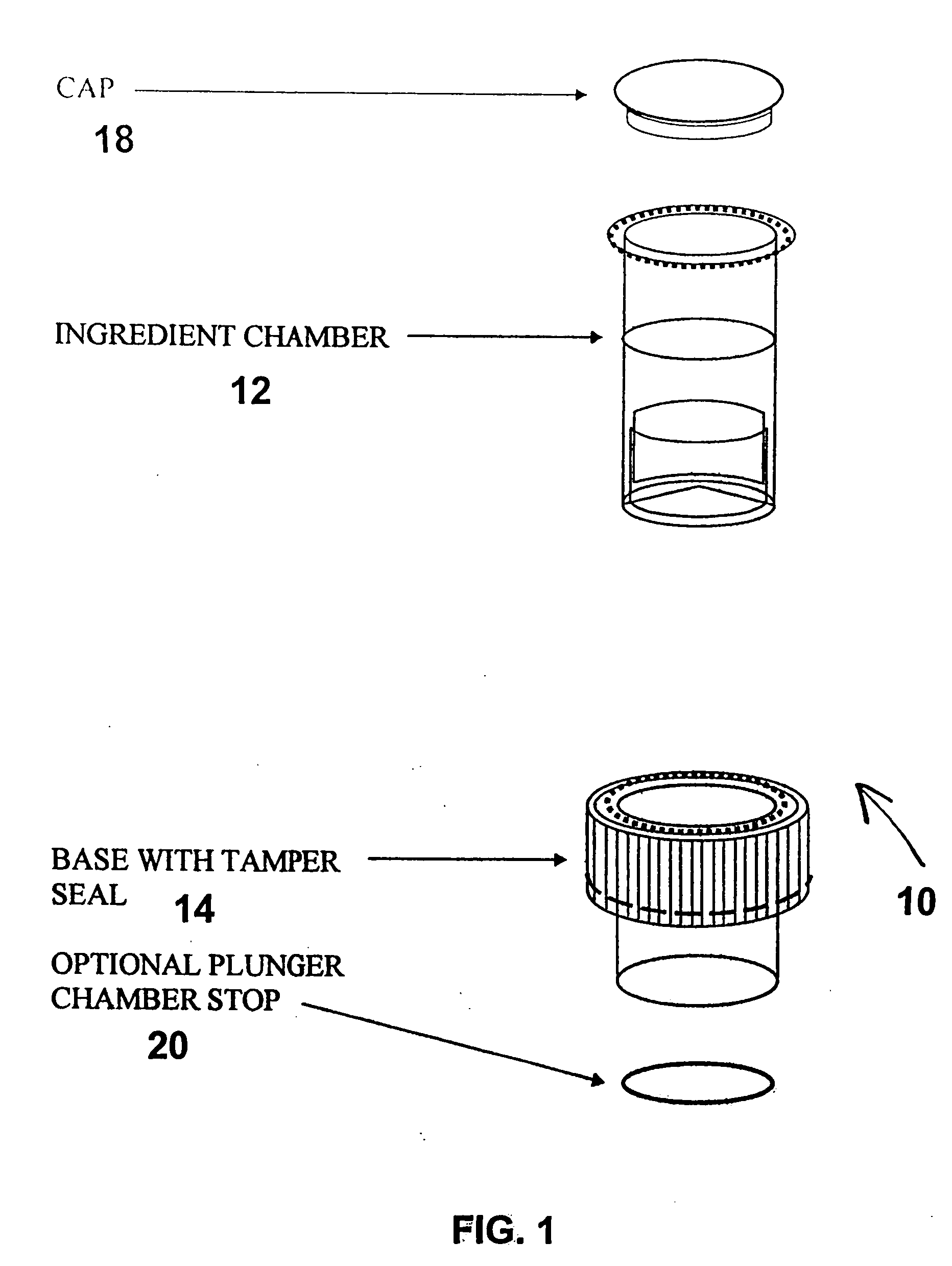

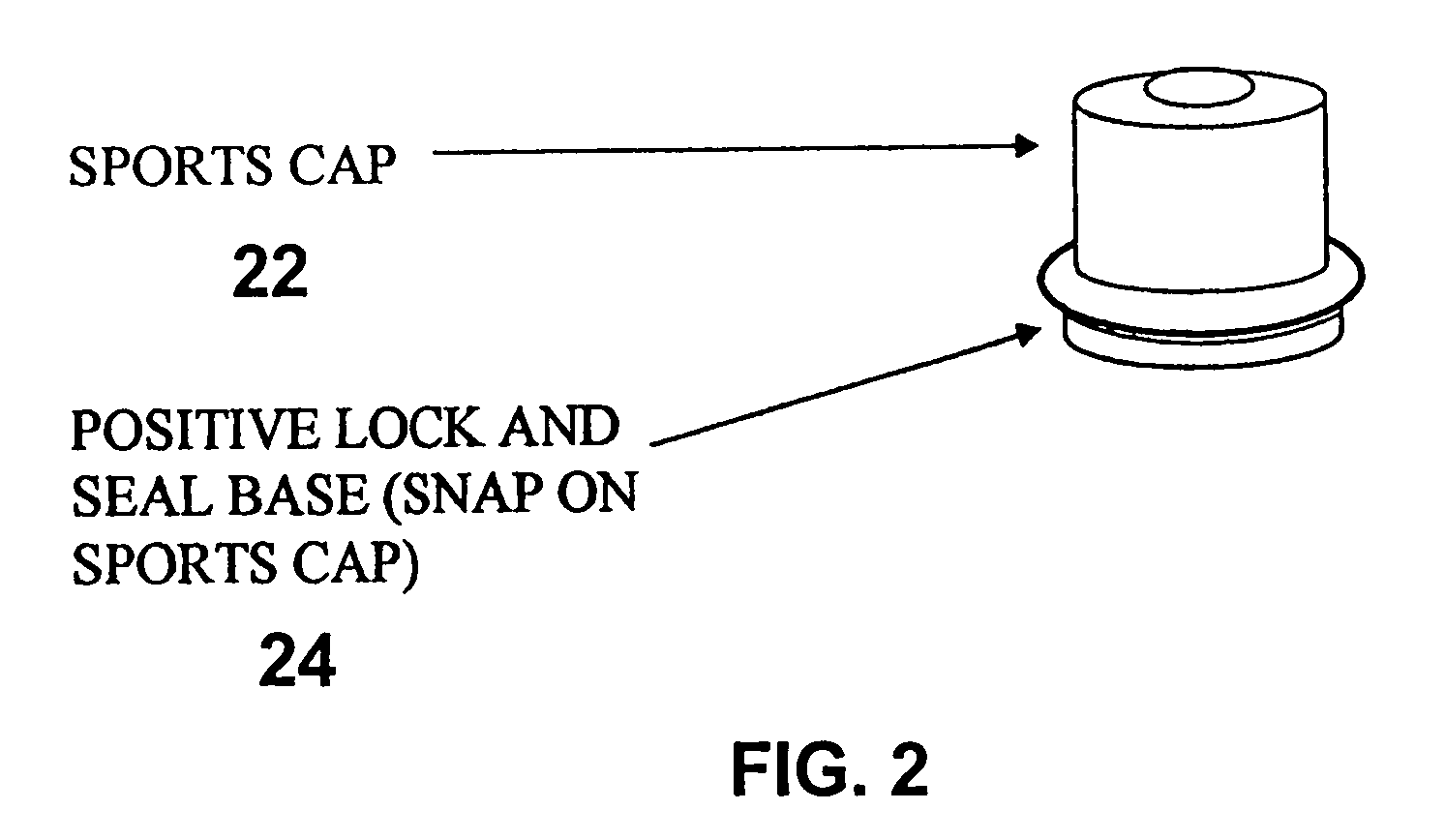

[0034]Referring to the accompanying drawings and initially to FIG. 1, it will be seen that a fresh product dispensing system 10 comprises an ingredient plunger / chamber 12, a base 14, with a tamper proof seal. The plunger / chamber 12 is enclosed by a cap 18. The bottom of the base may receive a stop 20. FIG. 2 illustrates a snap-on sports cap 22 with a positive lock seal base 24. FIG. 3 shows an alternative embodiment 25 of a dispensing system which has a molded in top 26 and a bottom fill seal 28. In FIG. 4, the molded top of FIG. 3 is replaced by a molded sports cap 30 to form another embodiment 35. As shown in FIGS. 3 and 4, a number of open radial ports 27 provide passages for the dry powder ingredients to exit the chamber 12 after the chamber is pushed down to release the powder into a bottle.

[0035]FIG. 5 illustrates a substantially assembled fresh product deliver system with a separated snap-on cap. A plunger 32 is positioned to be depressed to lower ports of the chamber through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com