Methods and apparatus for carrier-free deflection electrophoresis

a carrier-free deflection and electrophoresis technology, applied in the direction of liquid/fluent solid measurement, process and machine control, peptides, etc., can solve the problem of reducing the diffusion rate of analytes, unable to prevent the negative influence of the laminar flow profile for low-molecular analytes, and increasing the viscosity. problems, to achieve the effect of reducing the influence of the laminar flow profile, reducing the turn around time and reducing th

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

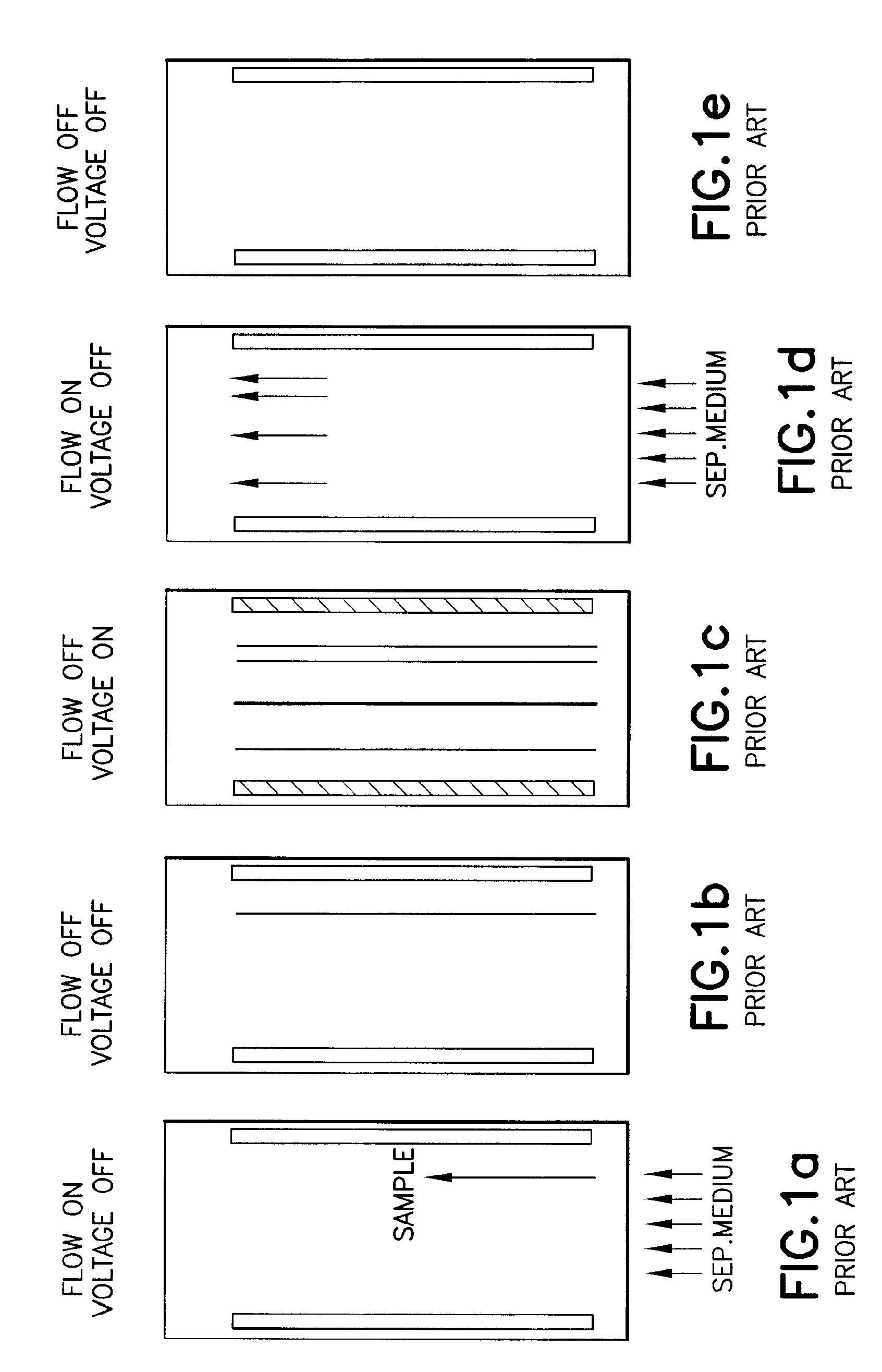

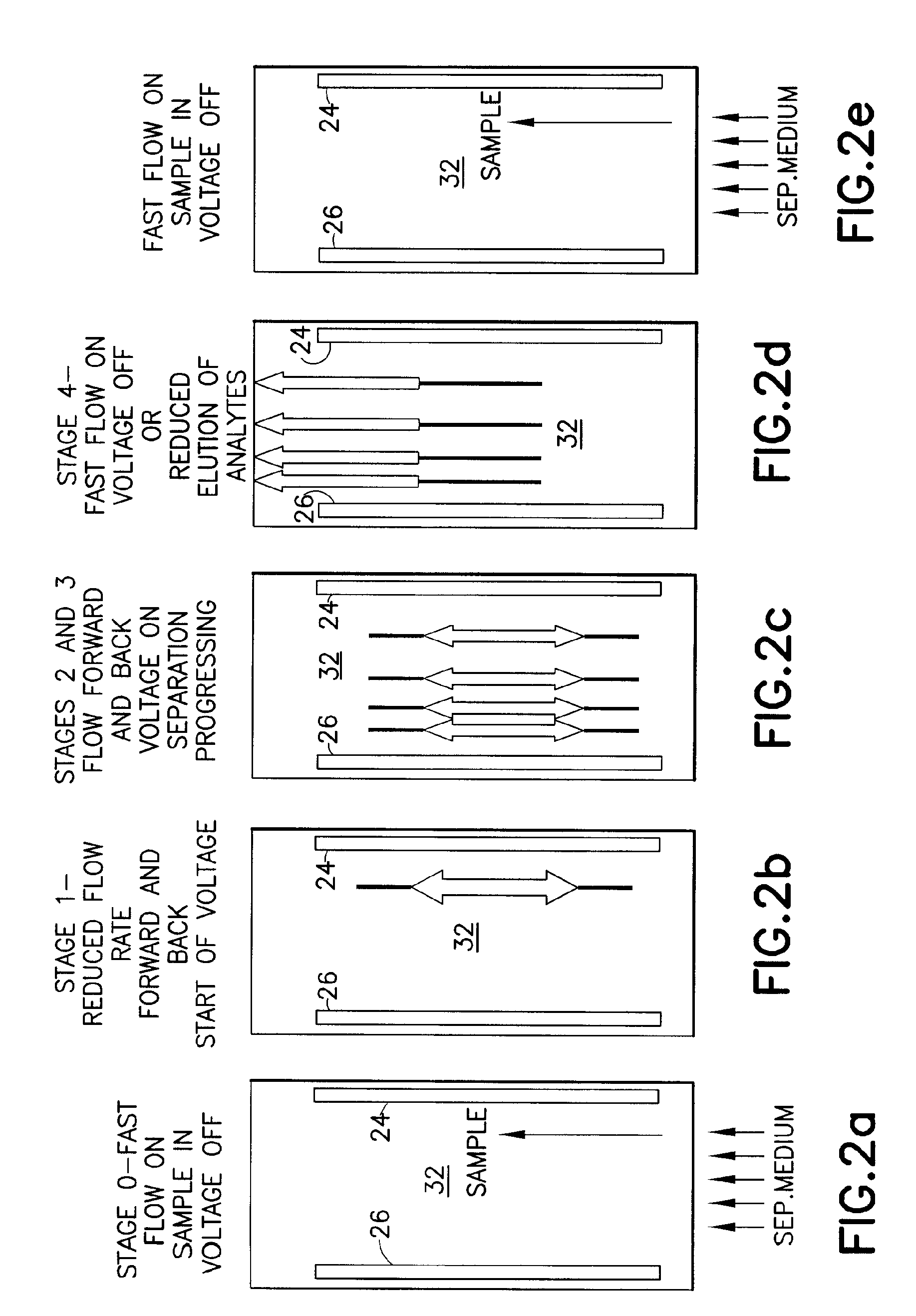

[0054]The present invention and its advantages are further illustrated in the following, non-limiting examples. In the drawings, like reference characters generally refer to the same parts throughout the different views. Also, the drawings are not necessarily to scale, emphasis instead being placed upon illustrating the principles of the invention.

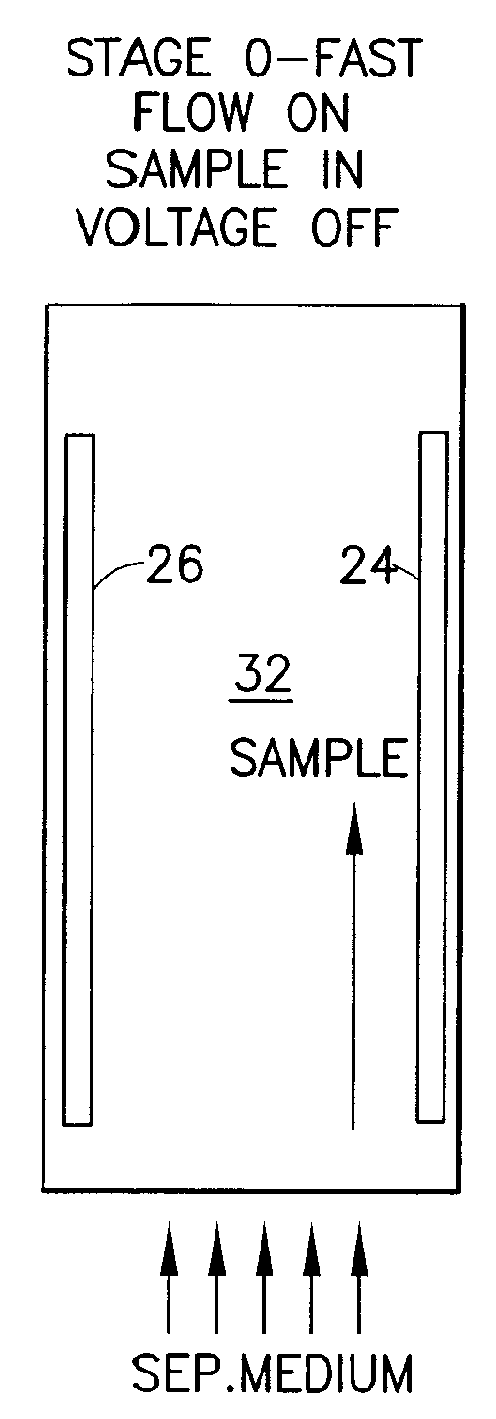

[0055]The general method of the present invention is reflected in FIG. 2 (specifically FIGS. 2a-2e) while the elements typically required for carrying out the invention are collectively described in FIGS. 3, 4, 7a, and 8a. Reflected schematically in FIGS. 3 and 4 are two embodiments of an electrophoresis apparatus 10 including an electrophoresis chamber 12 as well as elements relating to and / or connected to the electrophoresis chamber 12, while FIGS. 7a and 8a reflect specifically the electrophoresis chamber 12 as well as the electrophoretic behavior of the particles as schematically represented in the electrophoresis chamber 12.

[0056]An a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com