High strength steel sheet and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

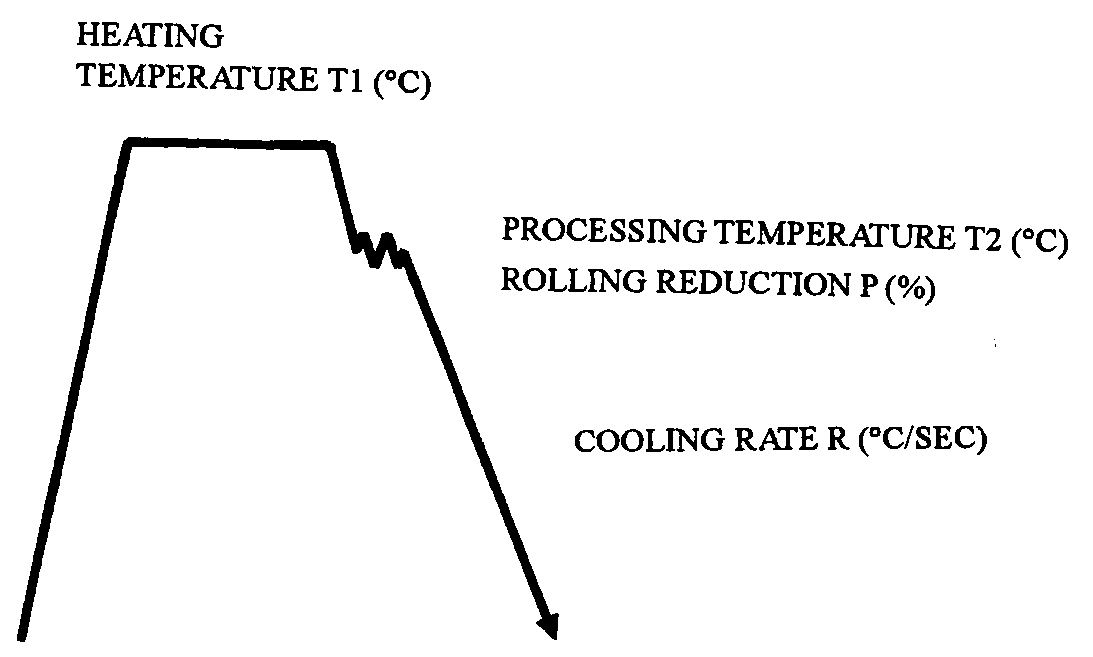

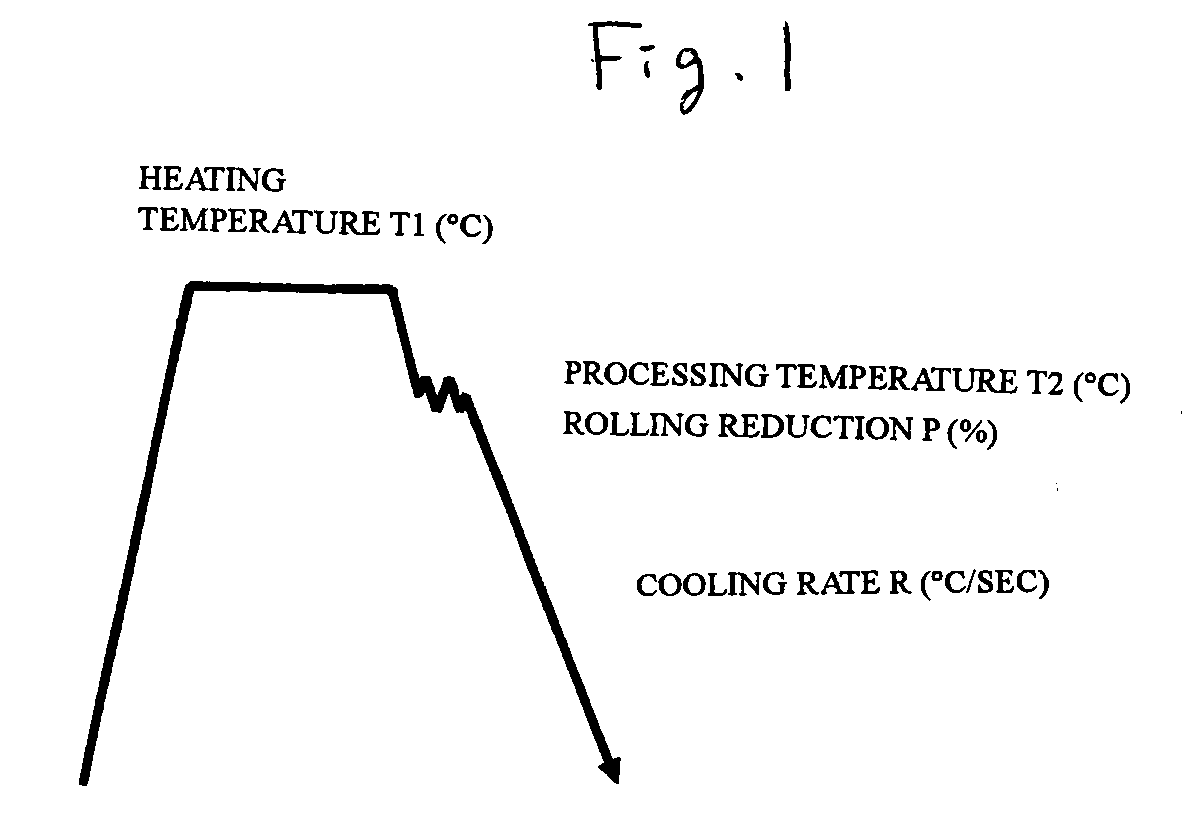

Method used

Image

Examples

example

[0109]Examples in the case that the secondary phase is martensite are described below.

[0110]Steels 1A to 5F having the component compositions shown in Tables 1 to 5 were melt to form slabs. The slabs were heated to 1,150° C., hot rolled to a sheet thickness of 3.0 mm at 800° C. and then taken up at 550° C. Surface scale was removed by acid pickling, followed by cold rolling to a sheet thickness of 1.2 mm. Each of the steel sheet materials thus obtained was heated and held at each temperature shown in Tables 6 to 9, and then subjected to heat treatment which cools to each stop temperature at a cooling rate shown in Tables 6 to 9.

TABLE 1Chemical component of specimenChemical component (mass %)Steel codeCSiMnPSAlBMoOtherAc3 (° C.)Ms point (° C.)Remarks1A0.0080.691.890.0080.0050.230.00090.87950476Comparison1B0.031.711.220.010.0050.170.00080.56969494Invention1C0.031.552.350.0080.0040.030.00050944448Invention1D0.081.281.310.0090.0060.130.00120.06912474Invention1E0.070.620.670.010.0050.260...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com