Multilevel sheet metal container with outwardly beaded end faces

a technology of end faces and end faces, which is applied in the direction of conveyors, bulk conveyors, packaging, etc., can solve the problems of trapped material in the grooves of the container, and achieve the effects of easy production and simple construction, eliminating or avoiding dead spaces, and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

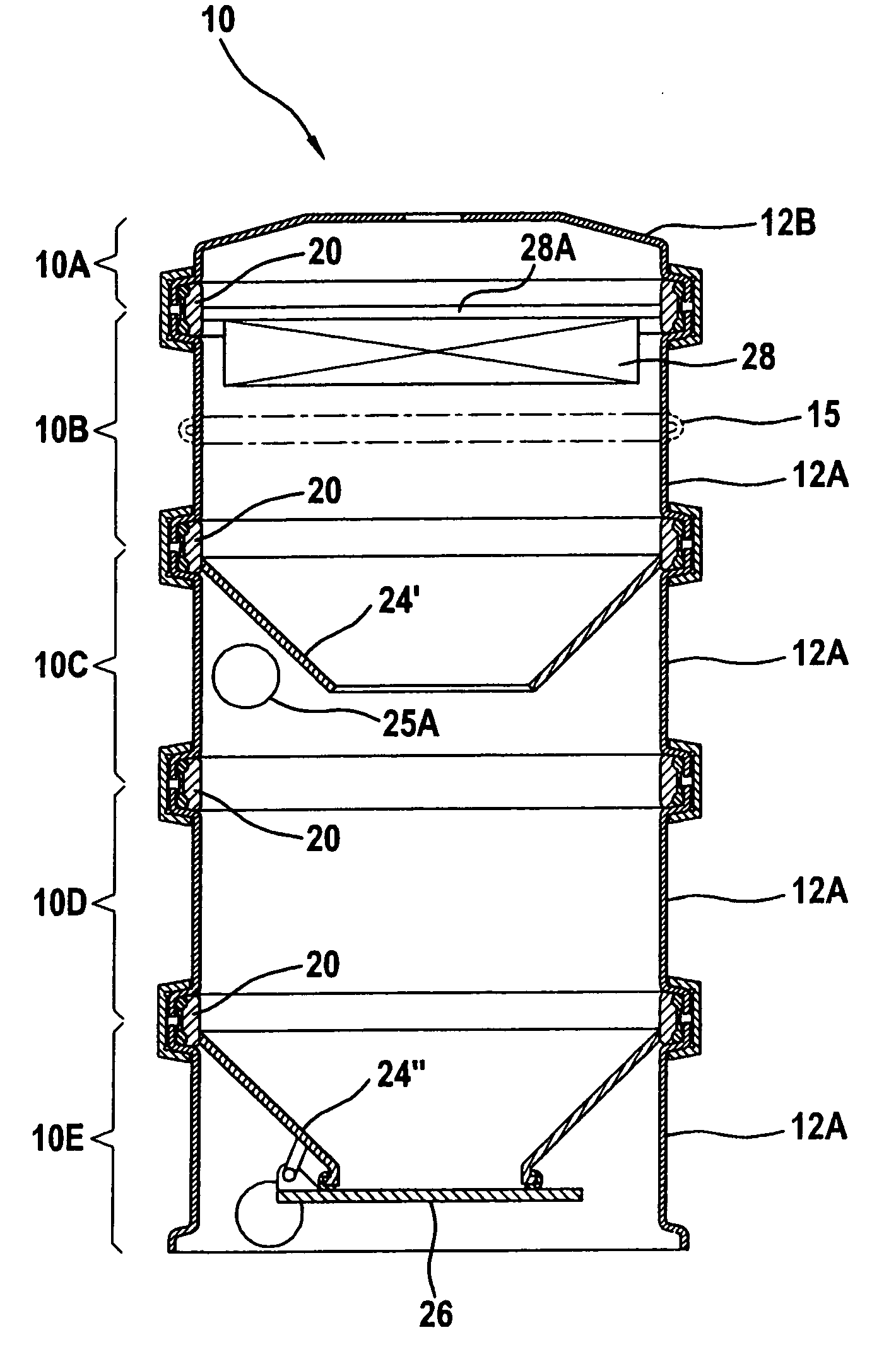

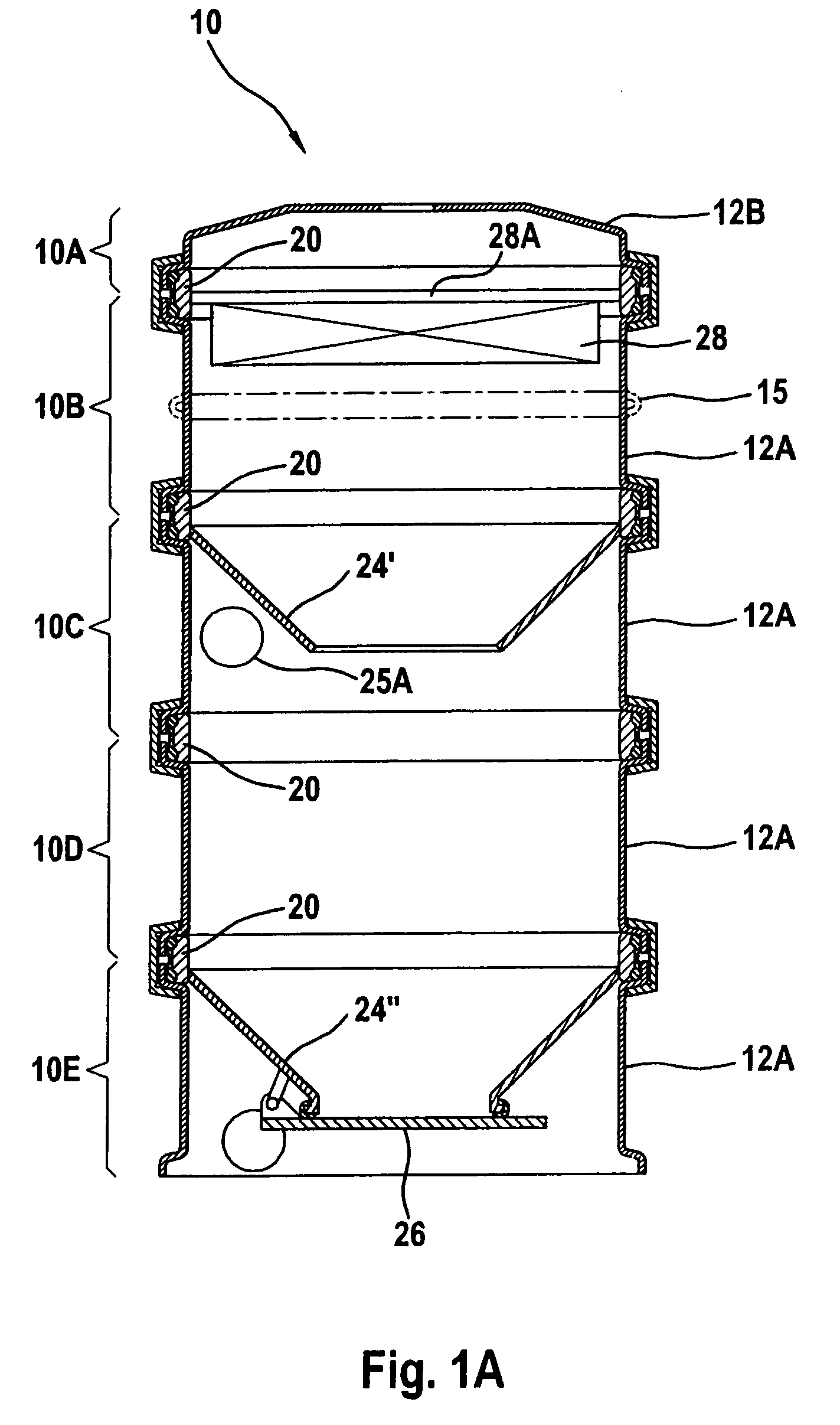

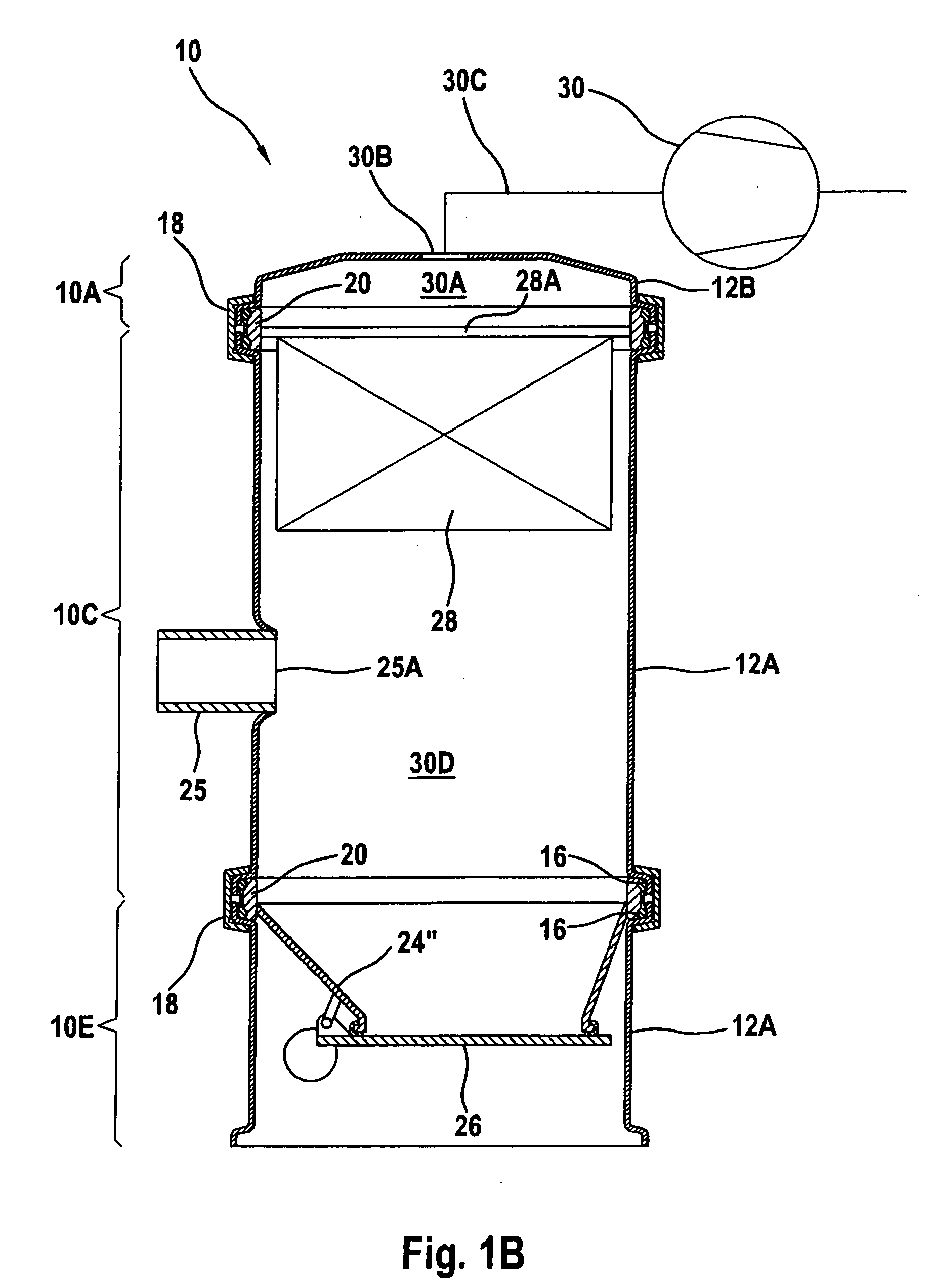

[0026]The five level container 10 with container levels 10A through 10E shown in FIG. 1A comprises four identical cylindrical, circumferentially continuous wall elements 12A and a pot-like bottom element 12B on its upper end. The lowermost wall element 12A serves merely as a supporting stand for mounting a discharge funnel 24″ which, on its tapered end, supports a throttle valve 26. Both this lower funnel 24″ as well as funnel 24′ located higher up and filter element 28 are supported on the radial inside surface of one shape retaining ring each. The funnels and the filter element can be continuously connected along the circumference to shape retaining ring 20 as described below, e.g., by means of welding. The butt-joints of container levels 10A through 10E are designed as shown in greater detail in FIGS. 2A through 2D and will be described below on the basis of FIG. 2A.

[0027]As FIG. 1A also shows, it is possible to provide container level 10C which serves as a cyclone so as to cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com