Nd-Fe-B type anisotropic exchange spring magnet and method of producing the same

a technology of anisotropy and exchange springs, which is applied in the field of anisotropy of rare earth permanent magnets and a method of producing magnets, can solve the problems of insufficient properties of obtained exchange spring magnets compared to theoretical properties, and achieve the effect of improving the magnetic properties of anisotropy exchange spring magnets and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

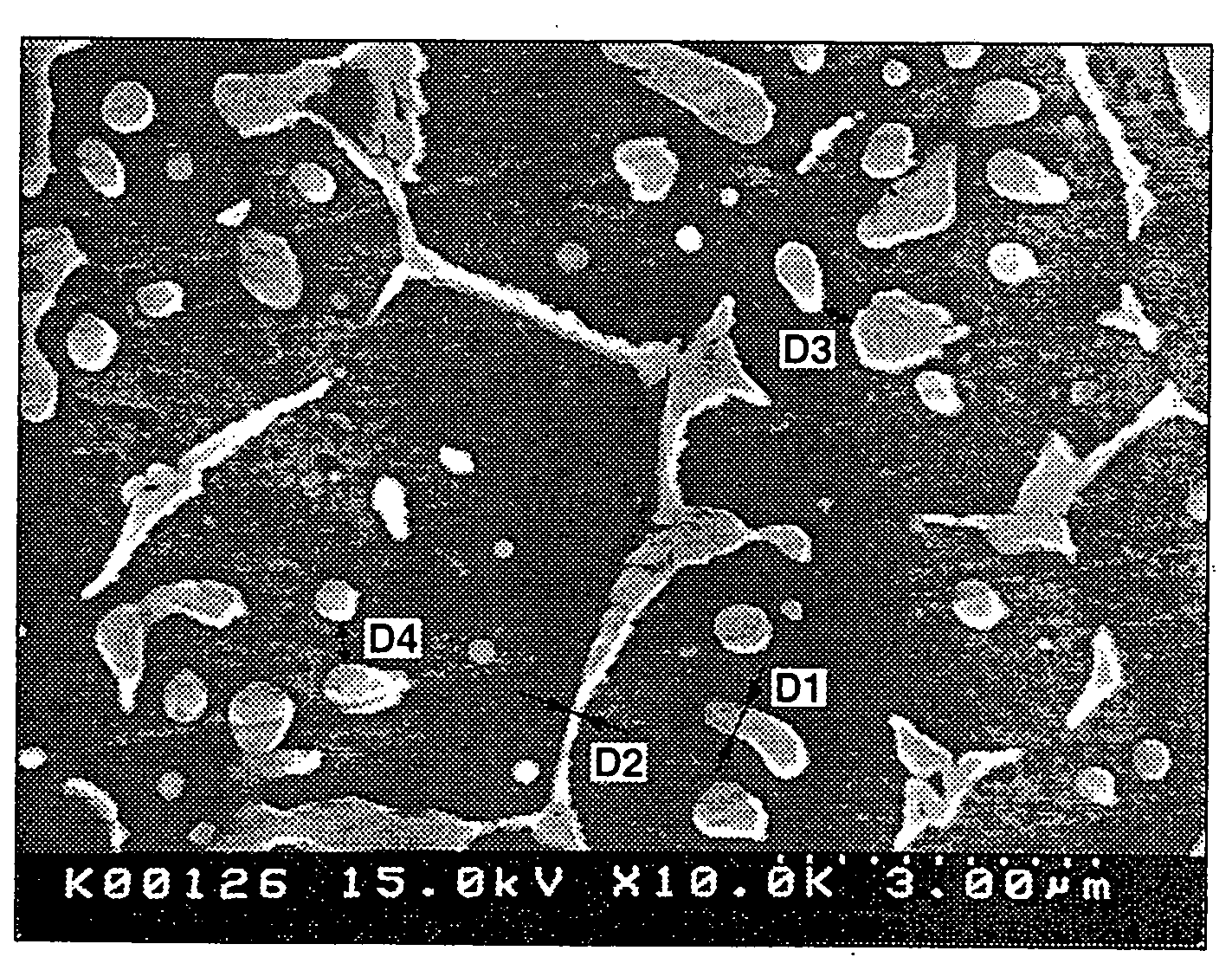

[0069]A thin strip of the rare earth magnet alloy was produced from an alloy ingot having a composition of Nd9.1Fe75.8CO8B6.1V1 by means of the strip casting method. A condition of the strip casting method was that a cooling speed for cooling the melted alloy to a solidification temperature of around 900° C. was set at 2300° C. / sec. By observing a cross-section of the thin strip alloy by means of a SEM (scanning electron microscope), it was confirmed that the thin strip alloy had a mixed structure of the hard magnetic phases and the soft magnetic phases. Substantially the minimum width of the soft magnetic phase was smaller than or equal to 1 μm, and the minimum distance between the soft magnetic phases was greater than or equal to 0.1 μm. The thin strip alloy had a structure such that a surface of the thin strip facing a roller of the strip casting method was more micro-structured than that of the other surface. FIG. 1 is a SEM photograph showing a center area of a cross section of...

example 2

[0077]A thin strip of the rare earth magnet alloy was produced from an alloy ingot having a composition of Nd10Fe75CO8B6V1 by means of the strip casting method and in the same manner as EXAMPLE 1. It was observed that the thin strip alloy has had a mixed structure of the hard magnetic phases and the soft magnetic phases, as a result of observing a cross-section of the thin strip alloy by means of SEM. Substantially the minimum width of the soft magnetic phases was smaller than or equal to 1 μm, and the minimum distance between the soft magnetic phases was greater than or equal to 0.2 μm. Powder for a VSM sample was produced by pulverizing the thin strip alloy into a size smaller than 25 μm using a set of mortar and pestle. The Js ratio of the VSM sample was 1.8.

example 3

[0078]A thin strip of the rare earth magnet alloy was produced from an alloy ingot having a composition of Nd11Fe74CO8B6V1 by means of the strip casting method and in the same manner as EXAMPLE I. It was observed that the thin strip alloy has had a mixed structure of the hard magnetic phases and the soft magnetic phases, as a result of observing a cross-section of the thin strip alloy by means of SEM. Substantially the minimum width of the soft magnetic phase was smaller than or equal to 1 μm, and the minimum distance between the soft magnetic phases was greater than or equal to 0.5 μm. Powder of a VSM sample was produced by pulverizing the thin strip alloy into a size smaller than 25 μm using a set of mortar and pestle. The Js ratio of the VSM sample was 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com