Method of manufacturing housing module gable

a housing module and manufacturing method technology, applied in the field of housing module manufacturing, can solve the problems of outmoded transportation methods, reliant on labor intensive technology, and the current modular industry has not yet achieved the full integration of mechanical and utility services as part of an automated production system, so as to reduce thermal conductance, reduce energy transfer, and eliminate the need for costly transportation trailers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

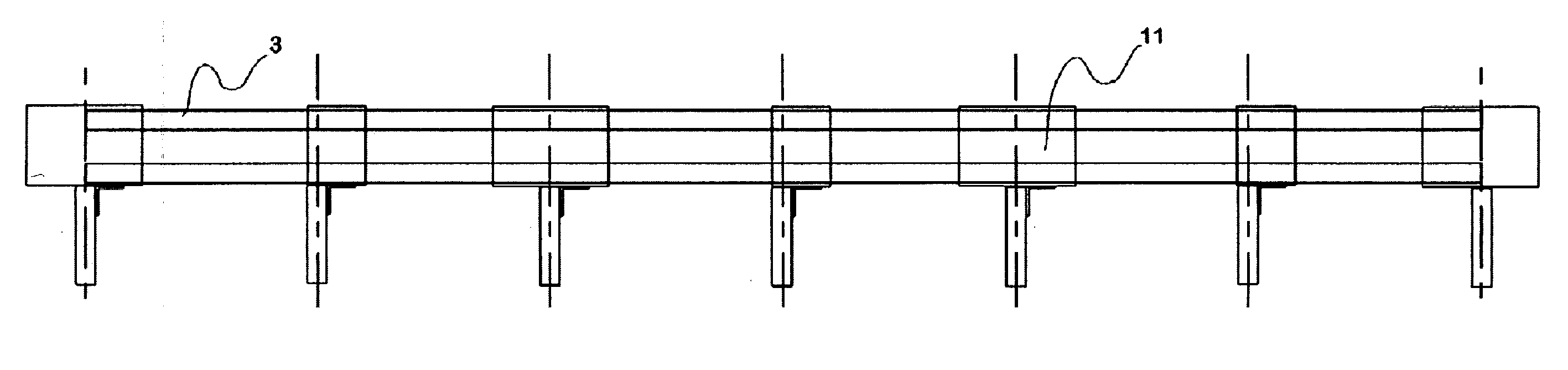

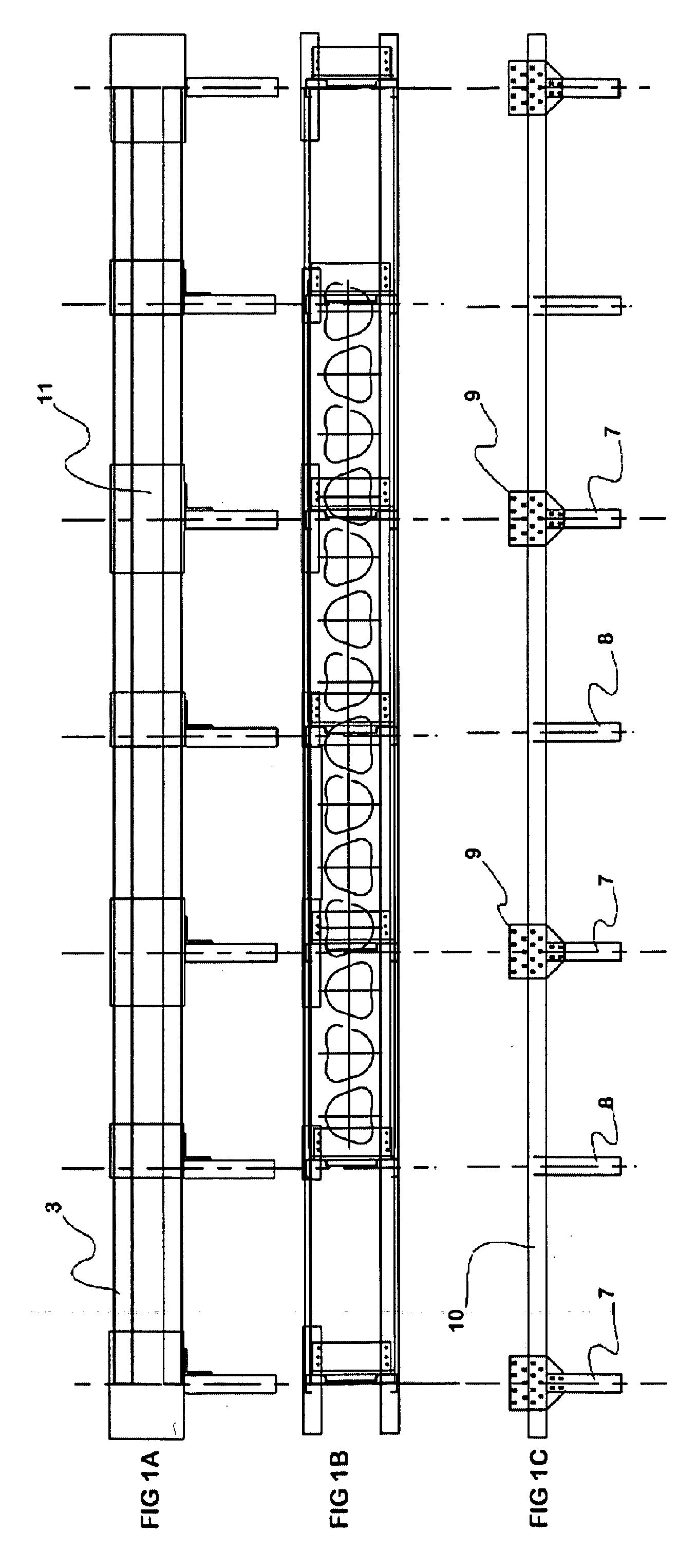

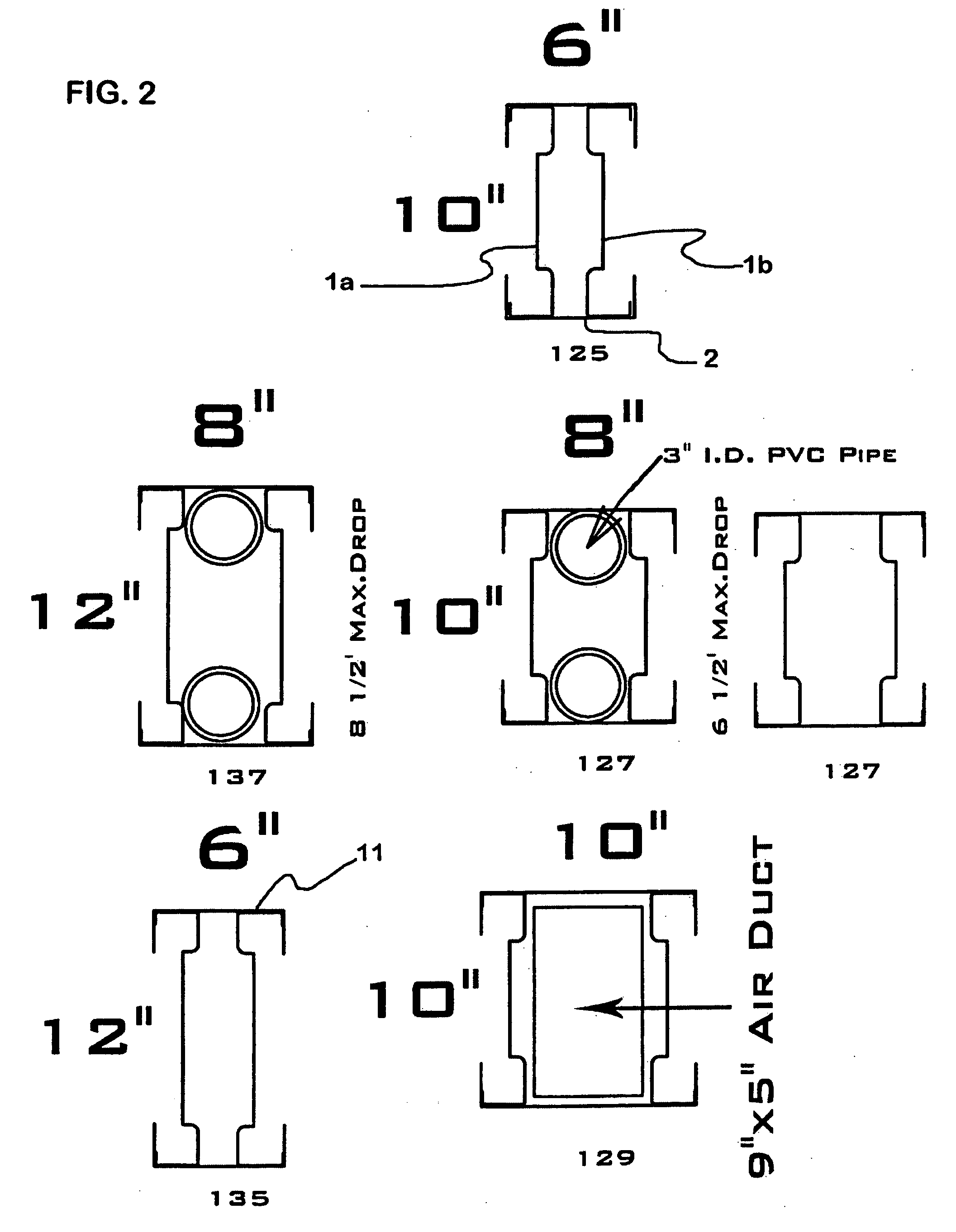

[0029]As shown in FIGS. 1A to 1C, an edge beam (EB) (3) is constructed of two vertical perforated rolled shapes (1a, 1b) having webs that are inverted toward the center of the beam and one bottom track (2) with the flanges in a vertical position against the bottom lips of the vertical rolled shapes. The two vertical members and the bottom track compose a U-shaped edge beam (3) having an open top to permit the insertion of mechanical and utility distribution in the longitudinal and transverse edge beams of the modules. The two vertical perforated rolled shapes (1a, 1b) function as compression members of the edge beam.

[0030]The three basic components of the edge beam are positioned so as to provide access for the press joining tools. In particular, the construction of the edge beams permits automatic insertion of the tool head so that the bottom flanges of the compression members can be press joined directly to the web of the bottom track (2) along the full length of the edge beam at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| energy properties | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com