Continuous process for the preparation of a reactive polymer

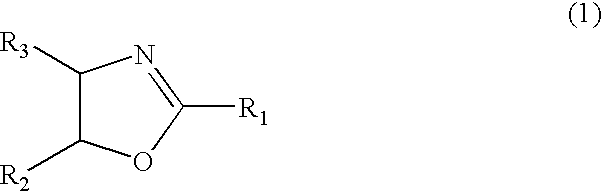

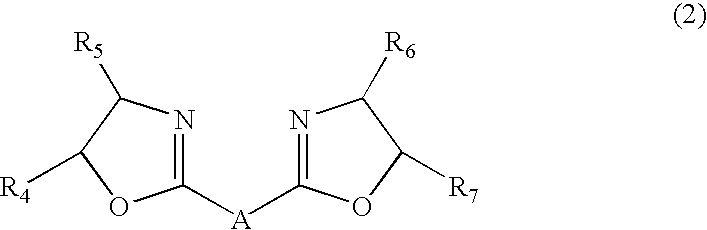

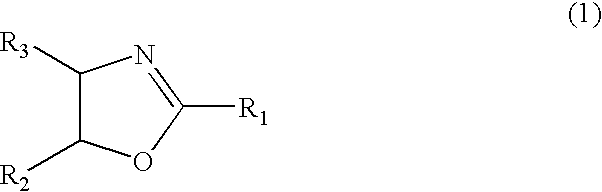

a technology of reactive polymer and continuous process, which is applied in the field of continuous process for the preparation of reactive polymer, can solve the problems of impeded continuous and exact metering of mono- and/or bisoxazoline via funnel, as mounted, and is extremely difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

[0074]7.67 kg of Ultramid B 40 (polyamide 6) and 1.89 kg of 1,3-phenylenebisoxazoline were metered in a Buss-Ko kneader at a cylinder temperature of 240° C. and a screw speed of 250 rpm via two independent metering devices. In this way, 9.20 kg of reactive polymer were obtained.

[0075]Characterization of the Reactive Polymer:

[0076]The water content of this reactive polymer was determined in accordance with DIN EN ISO 15512—process B and was 0.04% by weight.

[0077]The carboxyl end group content was determined by dissolving 2 g of the reactive polymer in benzyl alcohol and then titrating with methanolic KOH (titre solution: 0.05 mol / l) until the phenolphthalene colour indicator changes colour. The carboxyl end group content of the reactive polymer was <3 mmol / kg.

[0078]Determination of the elutable 1,3-phenylenebisoxazoline:

[0079]Each 15 g of the reactive polymer were extracted for 18 hours in a Soxhlet extractor in 100 ml of dichloromethane. The extract was concentrated in the nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com