Fully biodegradable plastic film and preparation method thereof

A plastic film and all-biological technology, which is applied in the field of fully biodegradable plastic film and its preparation, can solve the problems of difficult to obtain mechanical property mixtures, poor compatibility of PLA starch, etc., to reduce material costs, improve comprehensive performance, and high mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

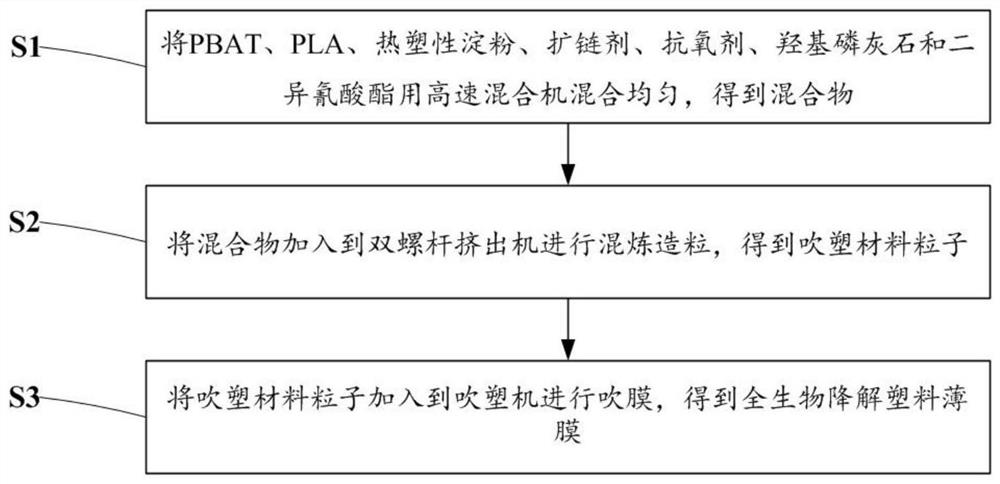

[0028] see figure 1 , the second aspect of the present invention provides a kind of preparation method of fully biodegradable plastic film, comprises the steps:

[0029] S1: Mix PBAT, PLA, thermoplastic starch, chain extender, antioxidant, hydroxyapatite and diisocyanate uniformly with a high-speed mixer to obtain a mixture. Wherein, the stirring speed of the high-speed mixer is 500-1000 r / min, and the stirring time is 5-20 minutes.

[0030] S2: adding the mixture to a twin-screw extruder for kneading and granulation to obtain blow molding material particles. Among them, the twin-screw extruder is preferably parallel to the twin-screw extruder, the temperature of the 1-10 zones of the twin-screw extruder is 145-155°C, the main engine speed is 100-150r / min, and the feeding speed is 1-150°C. 4r / min.

[0031] S3: Add the blow molding material particles to the blow molding machine to blow the film to obtain a fully biodegradable plastic film. Among them, the temperature of the...

Embodiment 1

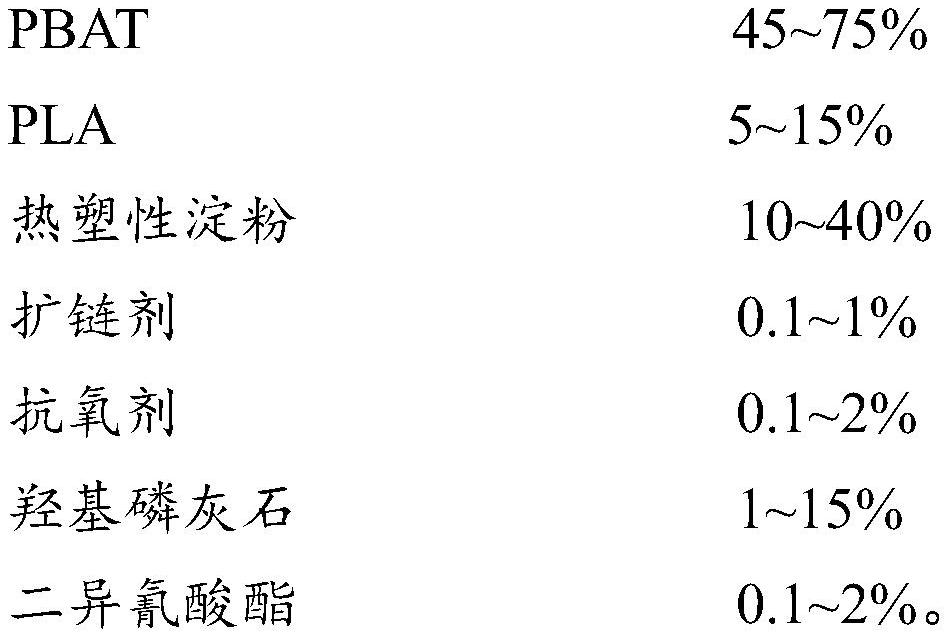

[0038] Embodiment 1 provides a kind of fully biodegradable plastic film, and the weight percent of its component is as follows:

[0039]

[0040]

[0041] The preparation method of this fully biodegradable plastic film comprises the following steps:

[0042] (1) Weigh PBAT, PLA, thermoplastic starch, chain extender ADR4468, antioxidant 1010, hydroxyapatite and IPDI according to the above formula, and mix them uniformly with a high-speed mixer to obtain a mixture. Wherein, the stirring speed of the high-speed mixer is 1000r / min, and the stirring time is 10min.

[0043] (2) Add the above mixture into a parallel twin-screw extruder for kneading and granulation to obtain blow molding material particles. Among them, the temperature of zones 1 to 10 of the twin-screw extruder is 150°C, the speed of the main machine is 120r / min, and the speed of feeding is 2r / min.

[0044] (3) Add the above-mentioned blow molding material particles into the hopper of the blow molding machine to...

Embodiment 2

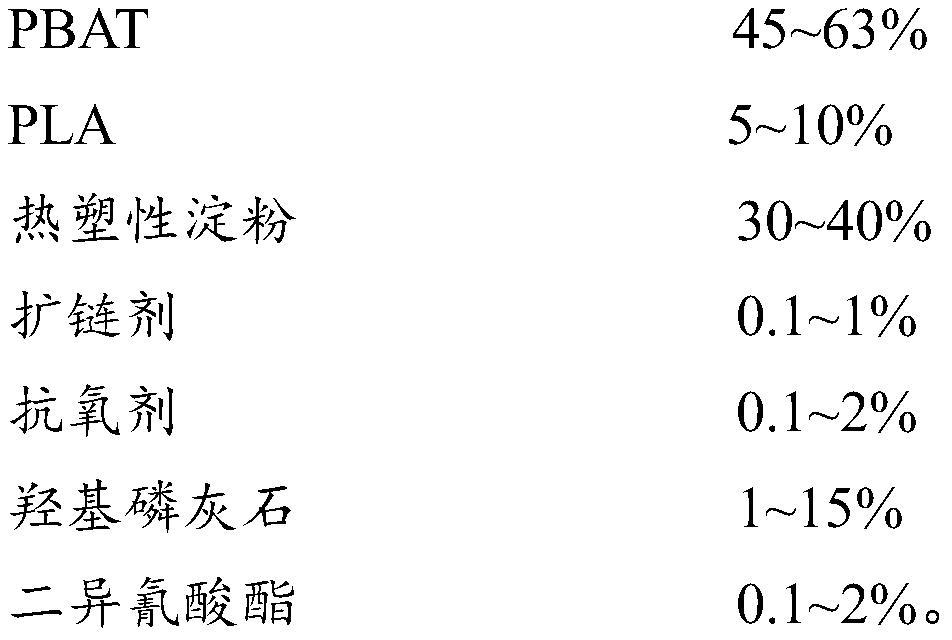

[0046] Embodiment 2 provides a kind of fully biodegradable plastic film, and the weight percent of its component is as follows:

[0047]

[0048] The preparation method of this fully biodegradable plastic film comprises the following steps:

[0049] (1) Weigh PBAT, PLA, thermoplastic starch, chain extender ADR4468, antioxidant 1010, hydroxyapatite and IPDI according to the above formula, and mix them uniformly with a high-speed mixer to obtain a mixture. Wherein, the stirring speed of the high-speed mixer is 1000r / min, and the stirring time is 10min.

[0050] (2) Add the above mixture into a parallel twin-screw extruder for kneading and granulation to obtain blow molding material particles. Among them, the temperature of zones 1 to 10 of the twin-screw extruder is 150°C, the speed of the main machine is 120r / min, and the speed of feeding is 2r / min.

[0051] (3) Add the above-mentioned blow molding material particles into the hopper of the blow molding machine to blow the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com