Machine And Method For Electrochemically Polishing Indentations Within An Aluminum Wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

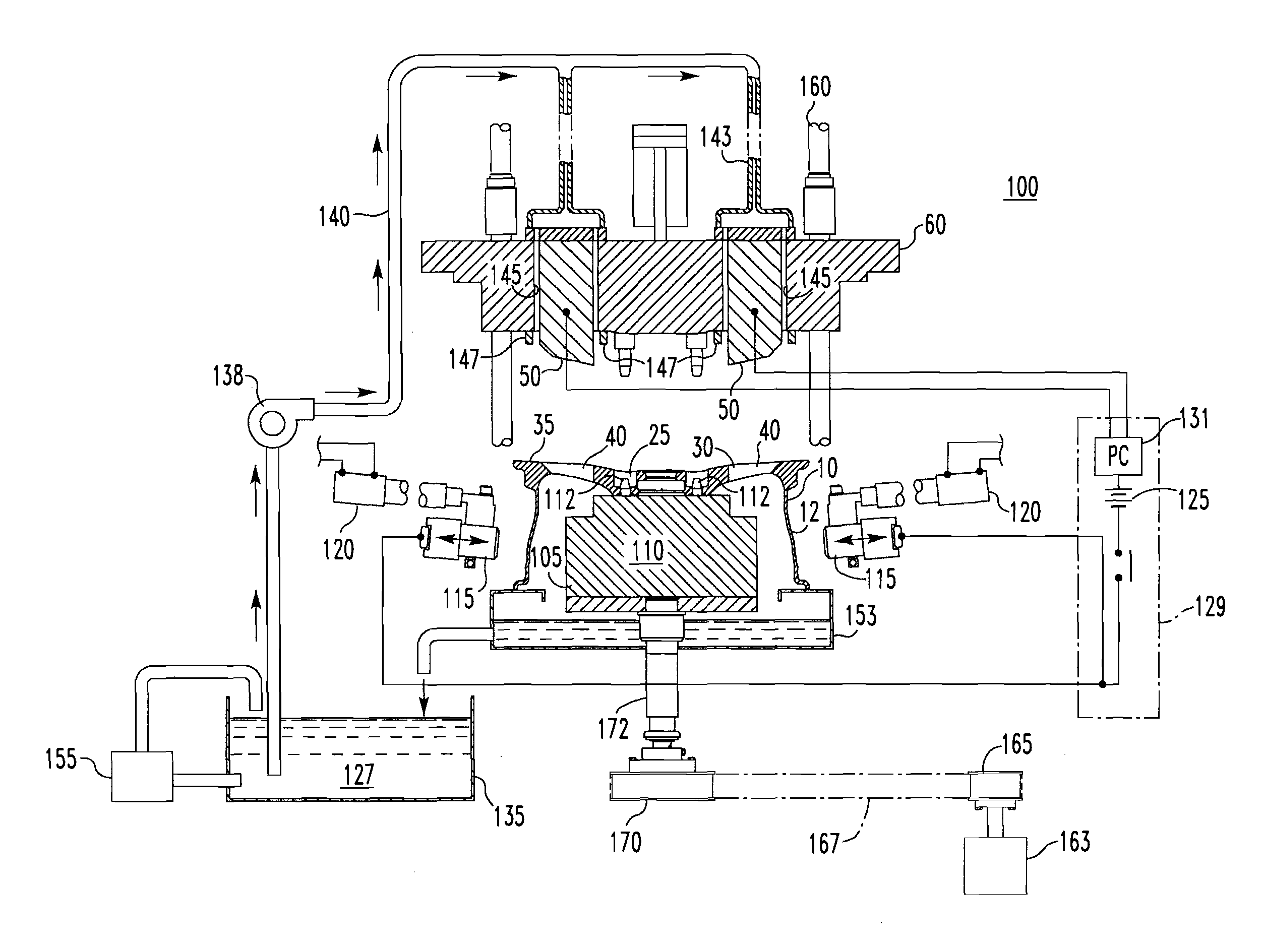

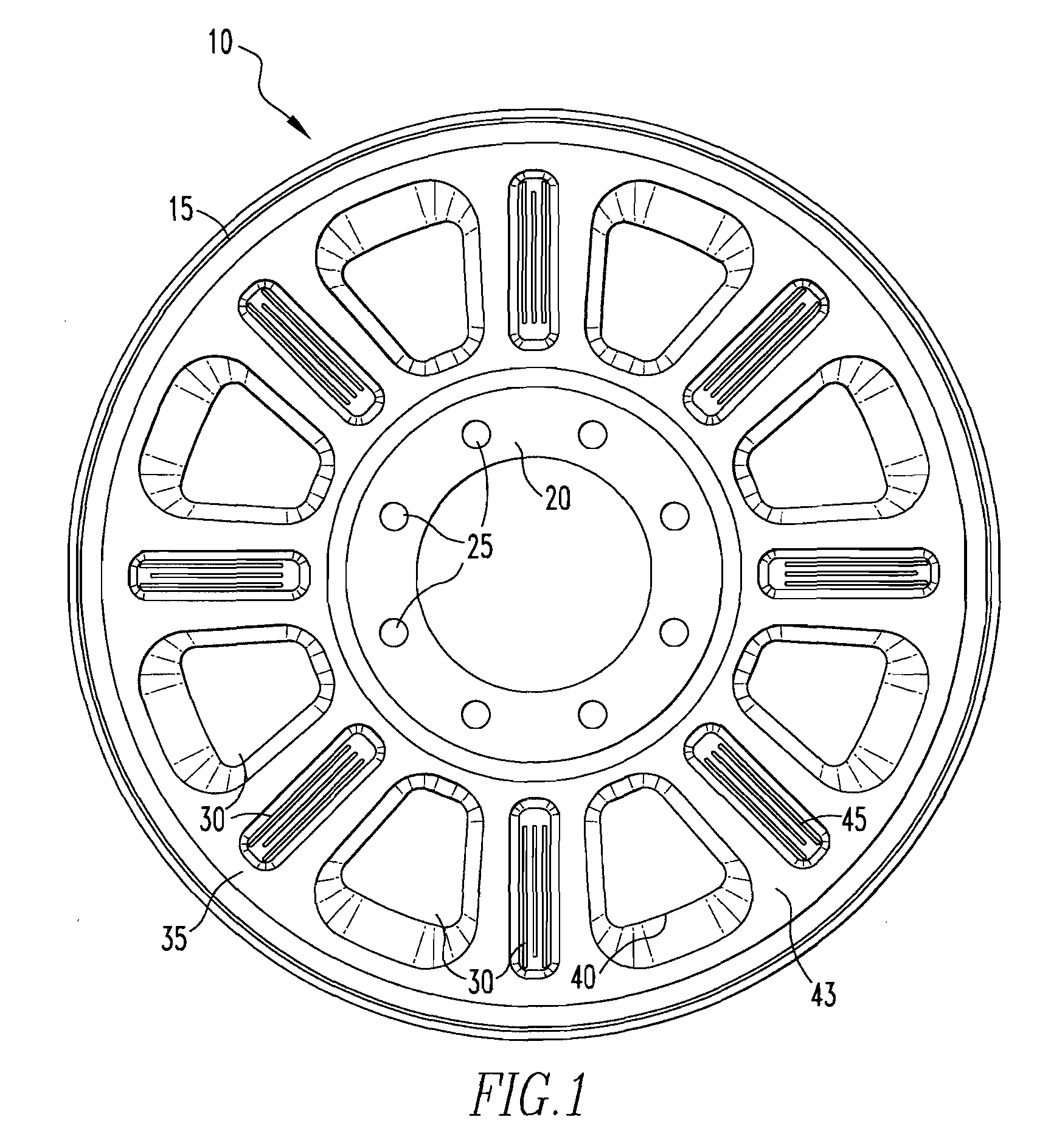

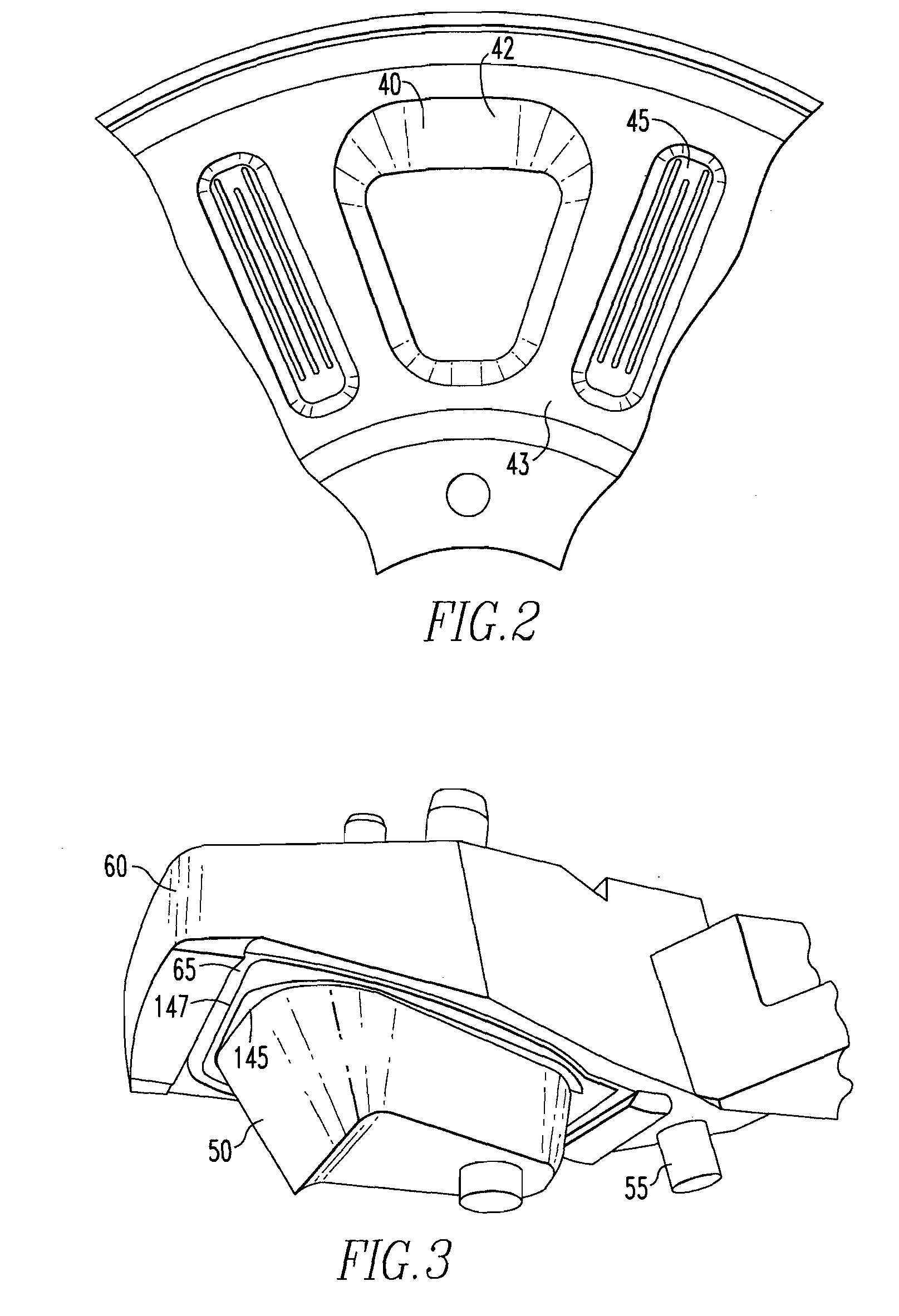

[0021]FIGS. 1 and 2 illustrate details of a typical workpiece, such as a wheel 10, which in these figures is an aluminum wheel having a cylindrical profile defining a wheel rim 15 which supports a tire (not shown) and a hub 20 having a plurality of lug holes 25 extending therethrough for securing the wheel 10 with lugs (not shown) extending from the body of a vehicle.

[0022]The wheel 10 has a plurality of indentations 30 of known geometry within the wall 35 of the wheel 10. In particular, an indentation 30 may be either a window 40 extending through the wall 35 of the wheel 10 or a pocket 45 which extends only partially through the wall 35 of the wheel 10. It should be appreciated that the electrochemical polishing process associated with the window 40 is slightly different than the process associated with the pocket 45. In particular, the electrolyte may be flushed through the window 40 during the process while the electrolyte must be introduced and removed from the pocket 45.

[0023]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap