Linear Compressor

a compressor and linear technology, applied in the direction of piston pumps, positive displacement liquid engines, pump parameters, etc., can solve the problems of increasing the pressure and temperature of refrigerants in the restricted space, reducing the efficiency of linear compressors, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]A linear compressor in accordance with preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

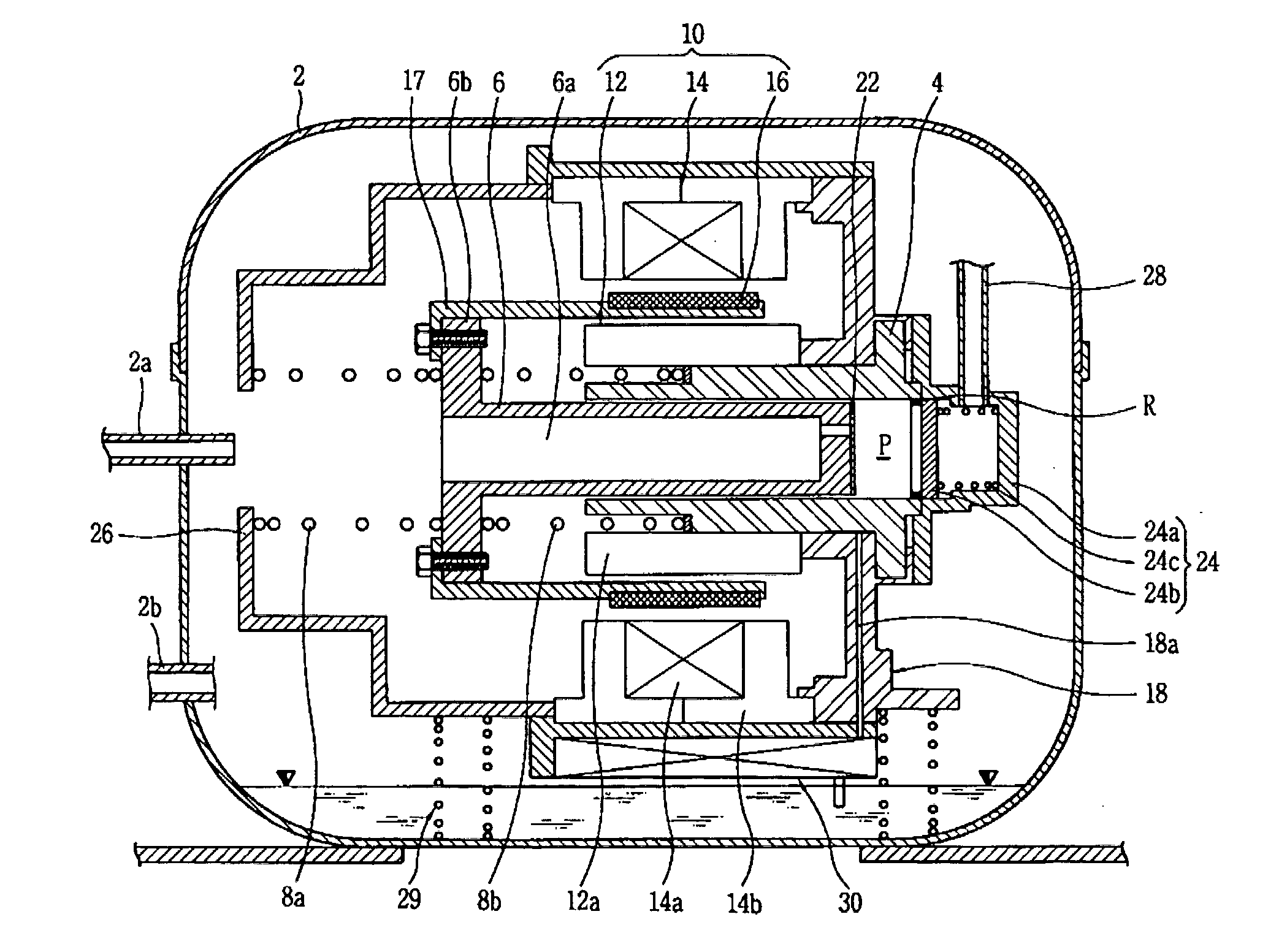

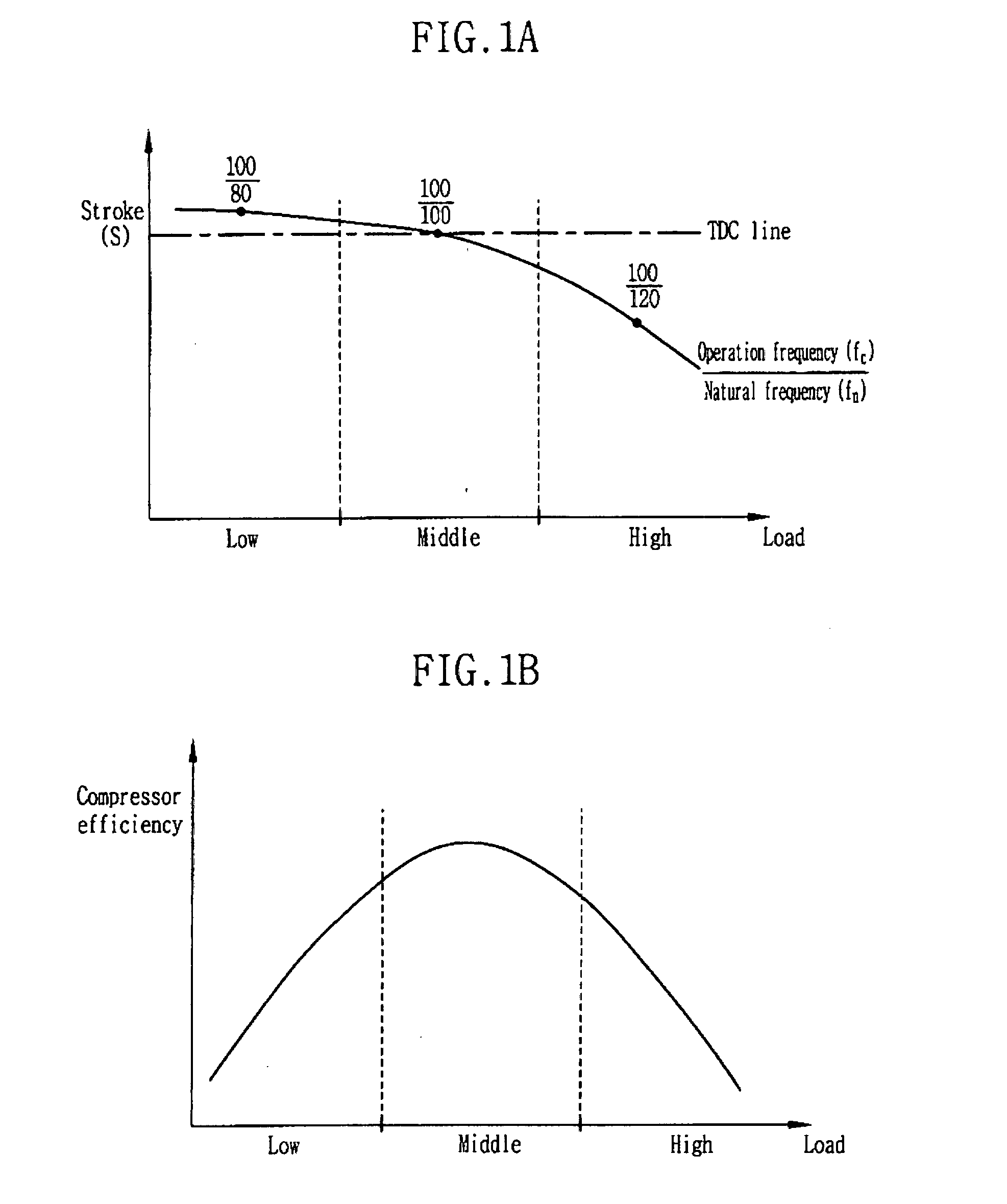

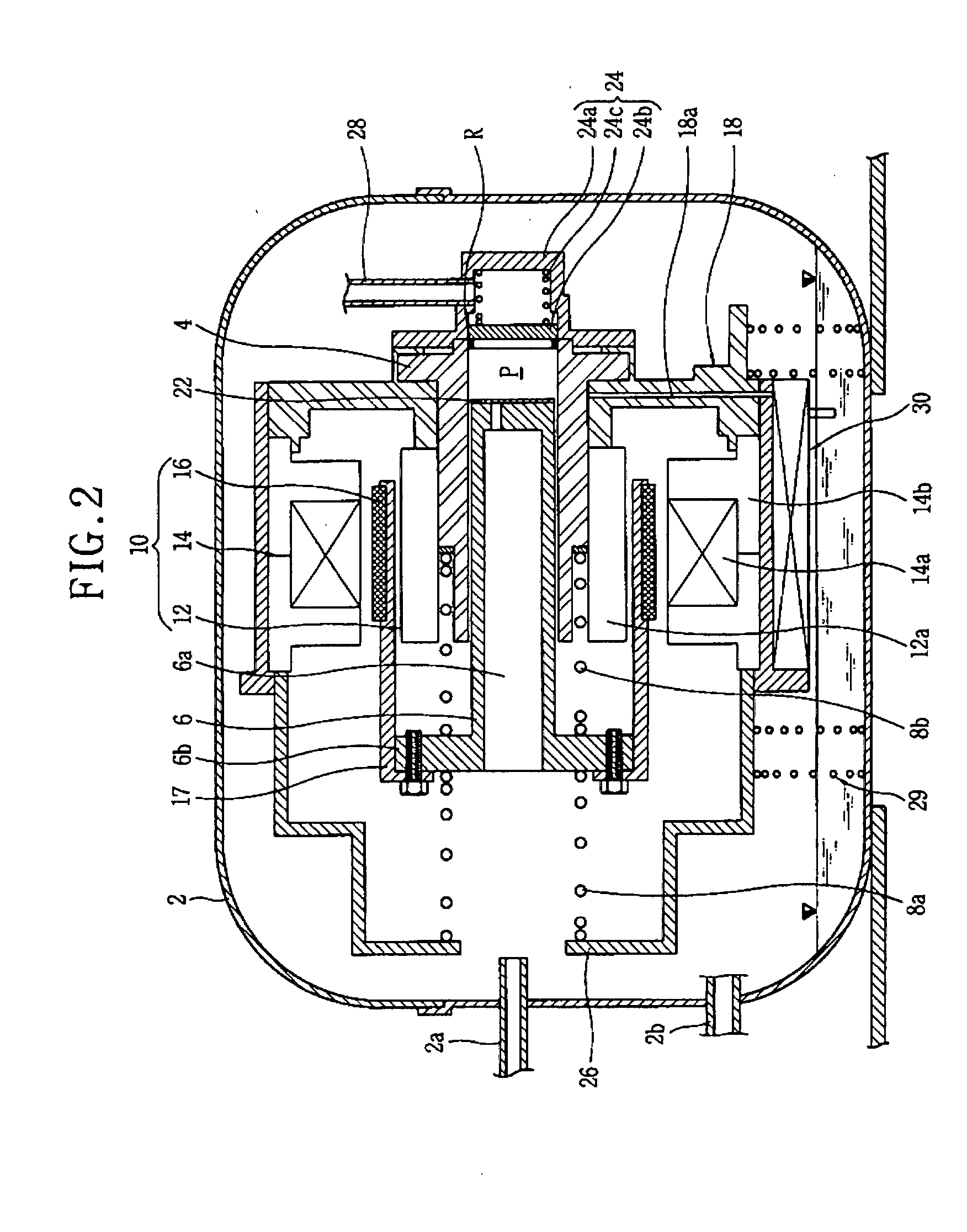

[0051]As shown in FIG. 2, in the linear compressor, an inlet tube 2a and an outlet tube 2b through which refrigerants are sucked and discharged are installed at one side of a closed vessel 2, a cylinder 4 is fixedly installed inside the closed vessel 2, a piston 6 is installed inside the cylinder 4 to be linearly reciprocated to compress the refrigerants sucked into a compression space P in the cylinder 4, and various springs are installed to be elastically supported in the motion direction of the piston 6. Here, the piston 6 is connected to a linear motor 10 for generating a linear reciprocation driving force. As depicted in FIGS. 3A and 3B, even if a natural frequency fn of the piston 6 is varied by load, the linear motor 10 controls its operation frequency fc to be synchronized with the natural frequency fn of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com