Biodegradable environment protective pad and method of manufacturing the same

a protective pad and biodegradable technology, applied in the field of biodegradable environment protective pads, can solve the problems of large environmental ecological harm, waste of several thousands of tons, and plastic solid waste coming with it, so as to reduce the load on the environment and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

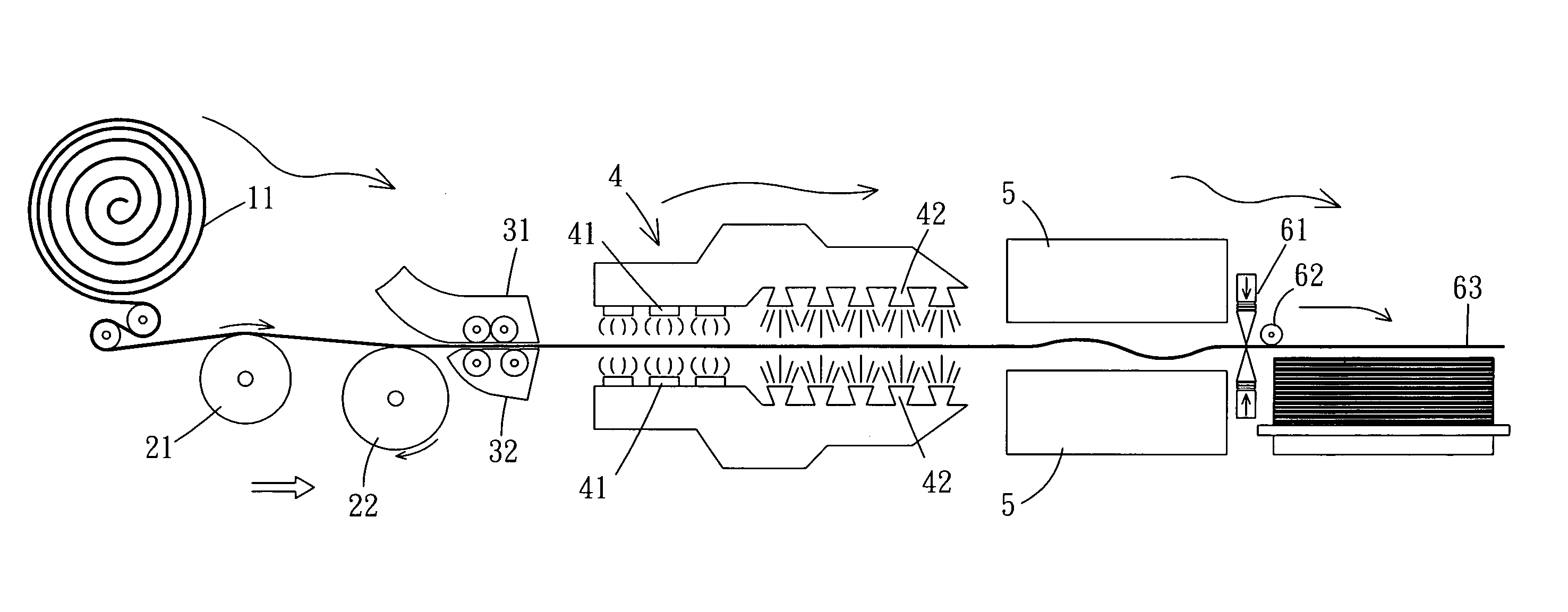

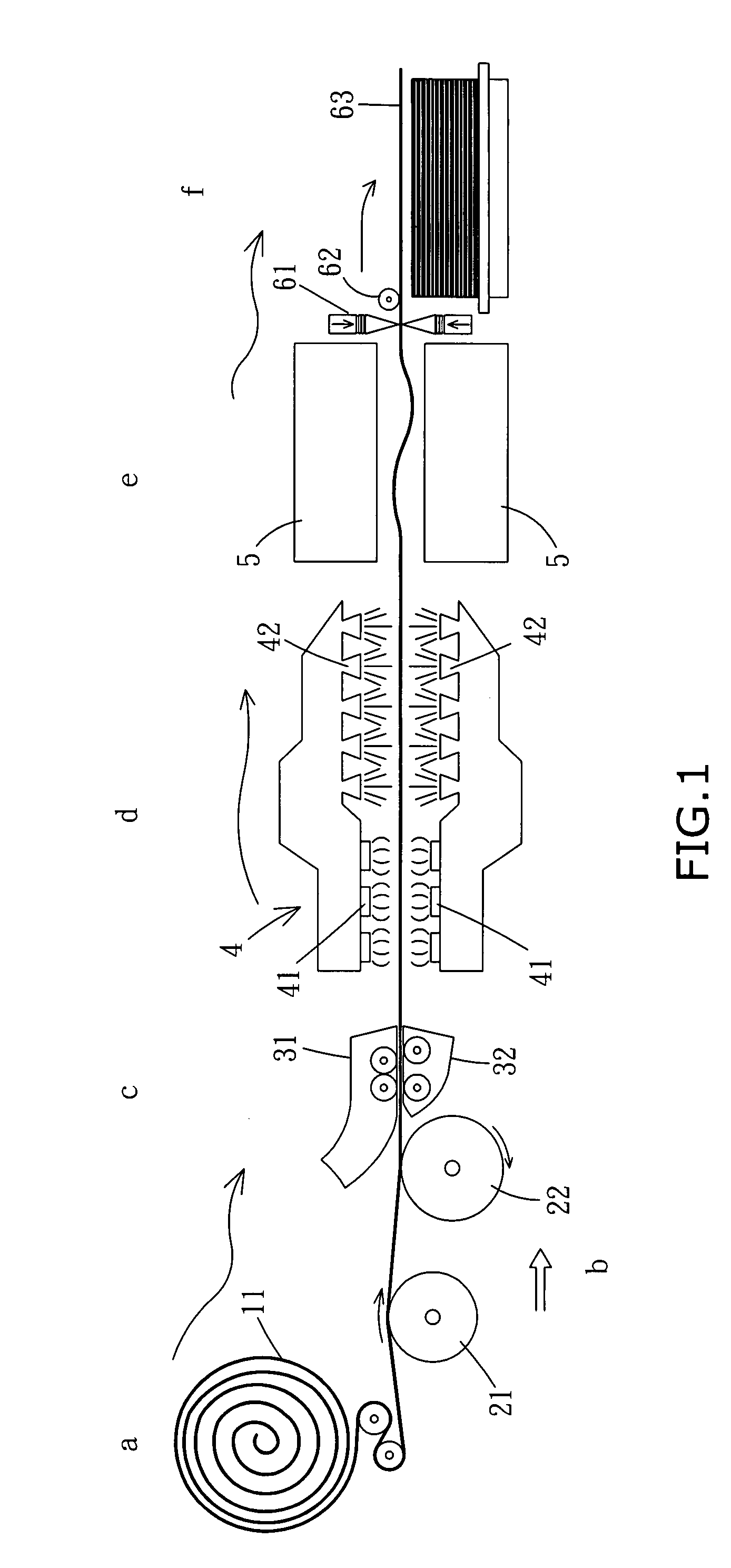

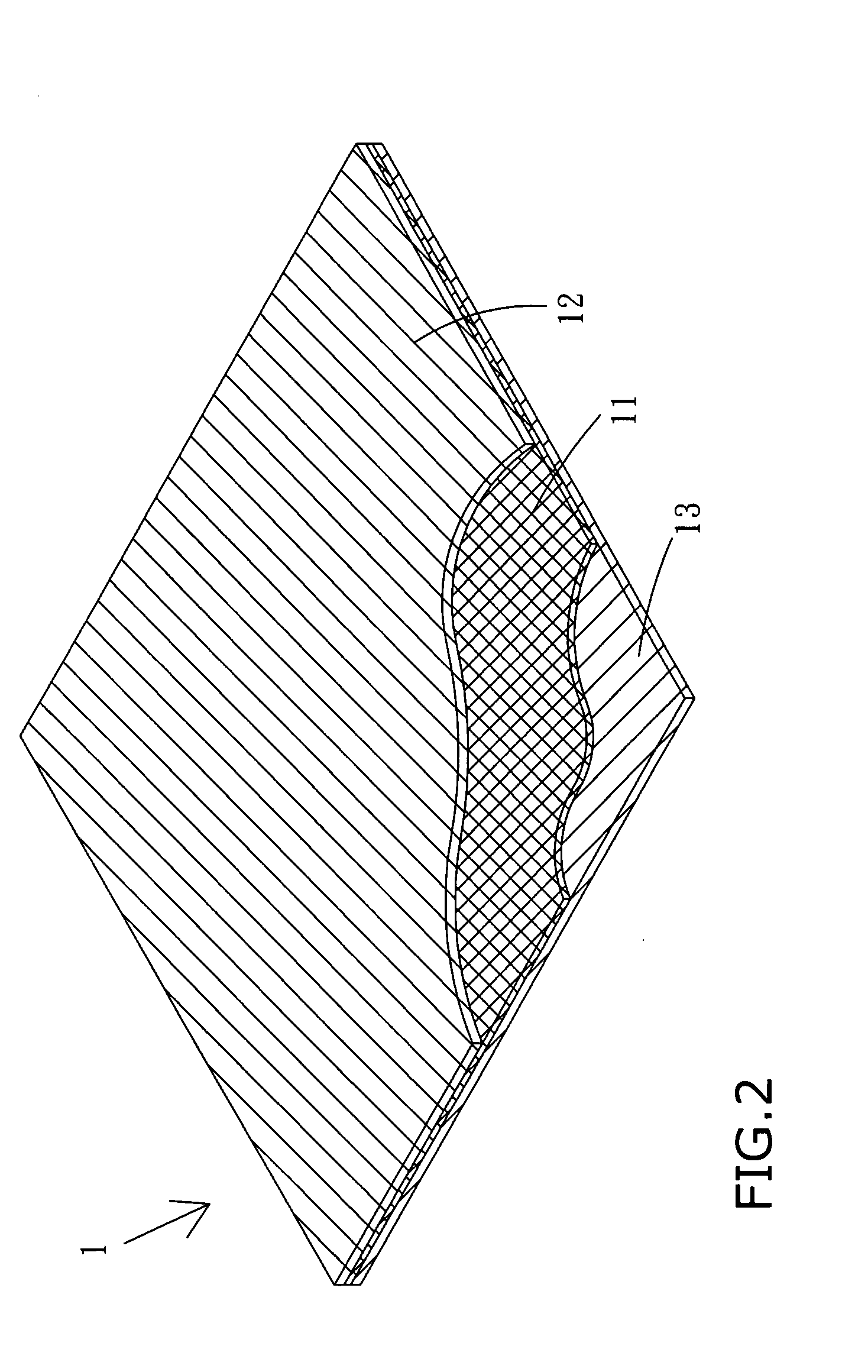

[0025]The invention provides a biodegradable environment protective pad and a method of manufacturing the same. The pad includes a polyester fiber or a natural woven material serving as a support frame, and a polymeric material (hereinafter referred to as PER material) formed of a predetermined formula is coated on the support frame. The biodegradable environment protective pad may be manufactured through a coating device storing the polymeric material and a build-in pressuring device, such as an air compressor, to perform the material dispensing, pressured coating, high-temperature drying and instantaneous cooling and hardening steps.

[0026]However, the used polymeric material, such as a polymer-natural including amylase or fibrin, does not have the high formability as the plastic, and the control of the property of the polymeric material and the facture usage is worse than that of the plastic material. Thus, the material ratio conversion of the property and the strict setting and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com