Fuel lance

a fuel lance and oxidator technology, applied in the field of lance, can solve the problems of increasing pollutant emission, poor mixing through, and relatively unfavorable combustion reactions, and achieve the effect of improving the cooling action of the oxidator flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

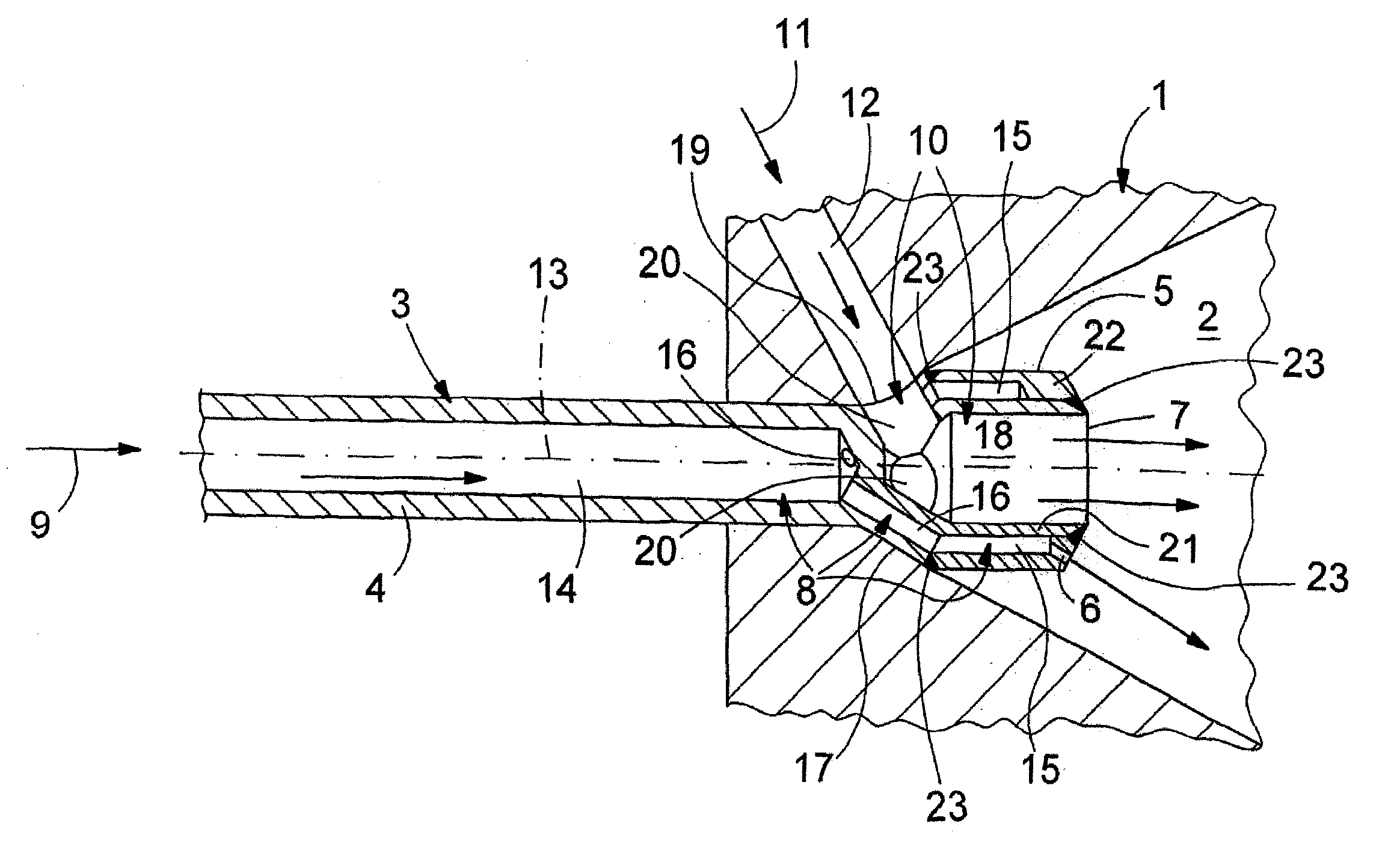

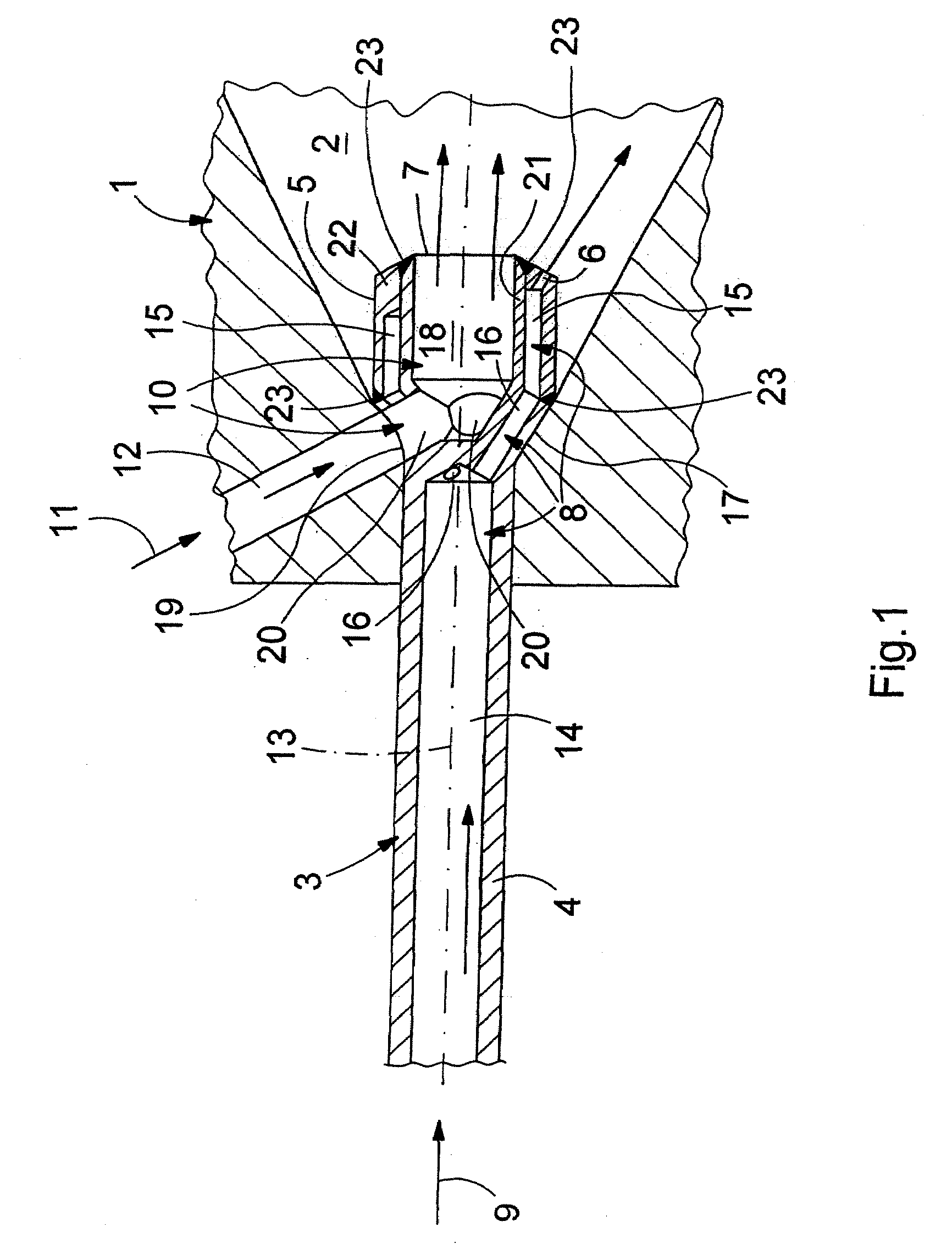

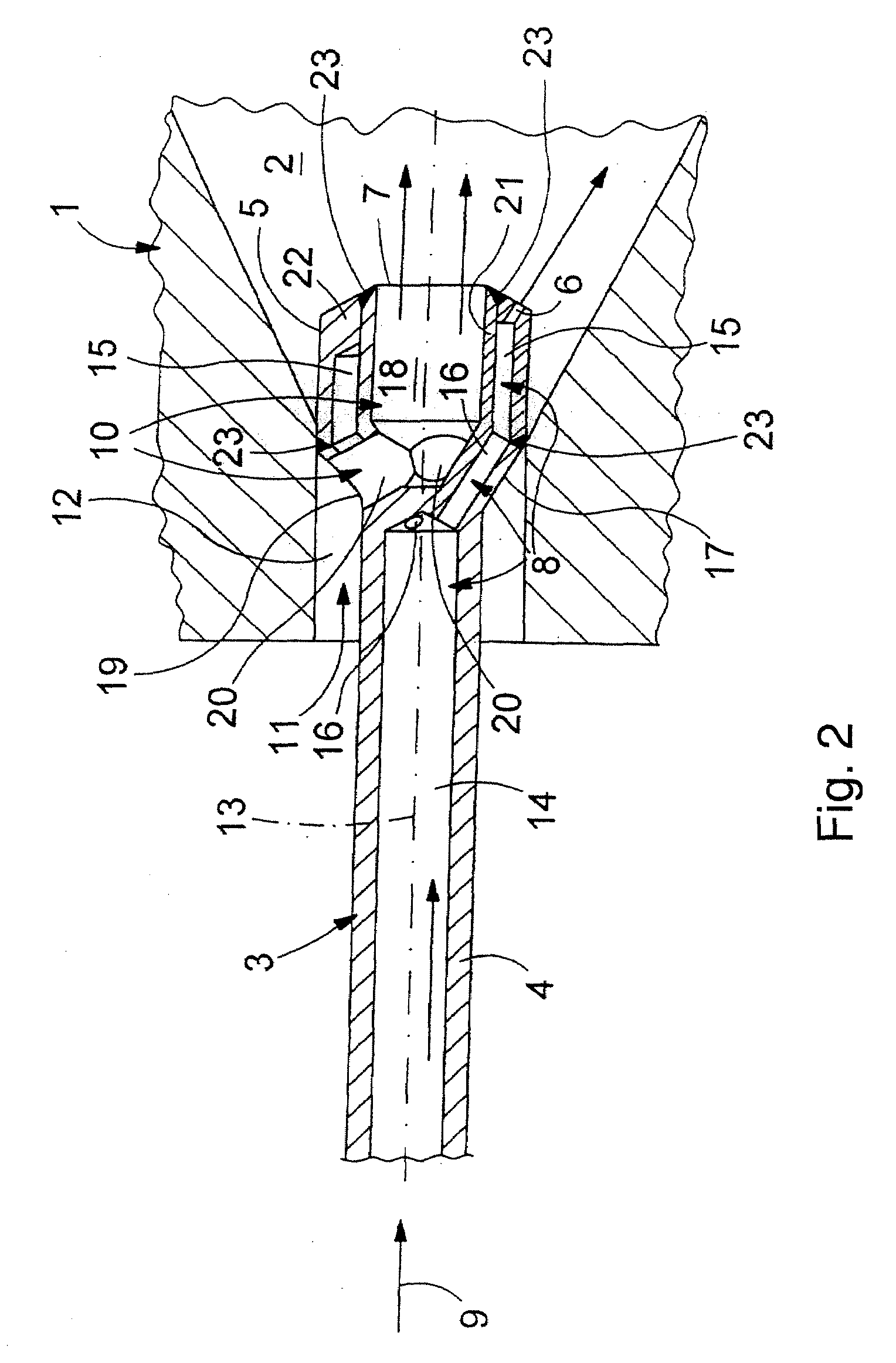

[0018]FIG. 1 accordingly illustrates a burner 1, which is only partially shown, which is equipped with a swirler, which is not shown, for producing a swirled combustion air flow, and a mixing path 2 which leads to a combustion chamber, which is not shown. This mixing path 2 can also be designated as a combustion chamber. In this case, the burner 1 can be a component part of a turbine plant, especially a gas turbine plant. The burner 1, in the head section on the inlet side which is shown here, is provided with a lance 3, by which a fuel can be introduced into the mixing path 2. As is generally known, such lances are separate component parts, which are movably installed in the burner and which can also be relatively simply withdrawn, should the occasion arise.

[0019]The lance 3 includes a lance shank 4 and also a lance head 5 which is installed or formed on the lance shank 4 on the end which is allocated to the burner 1. In the installed state which is shown, the lance head 5 projects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com