Pavement marker, kit and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

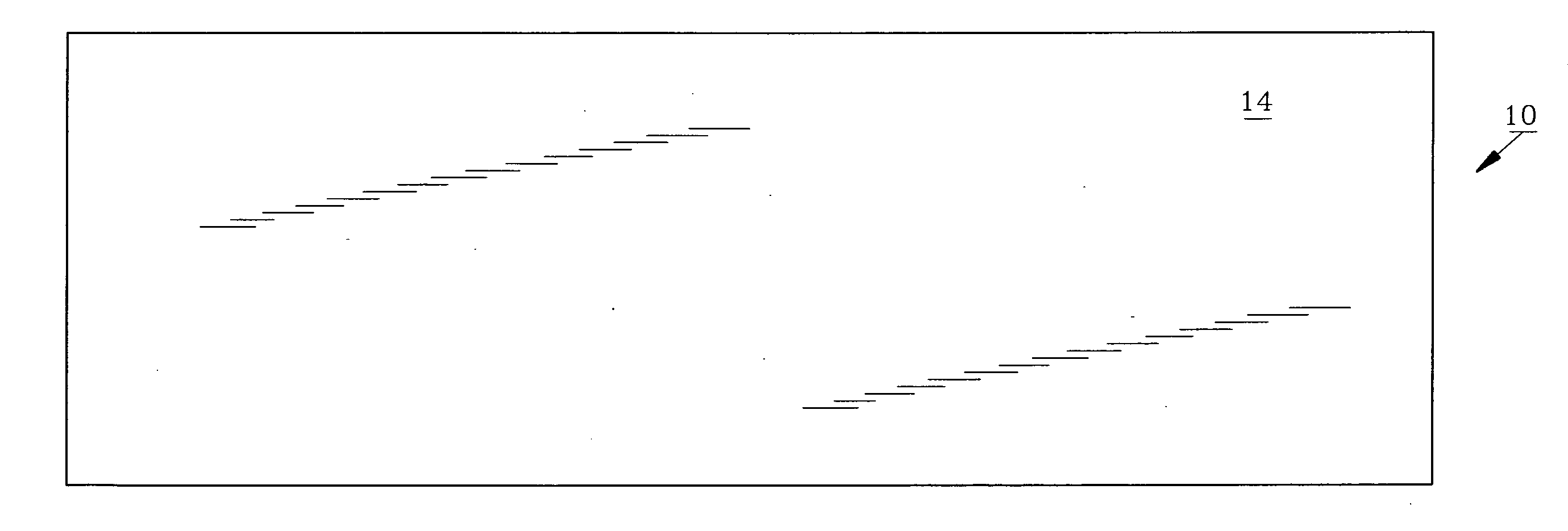

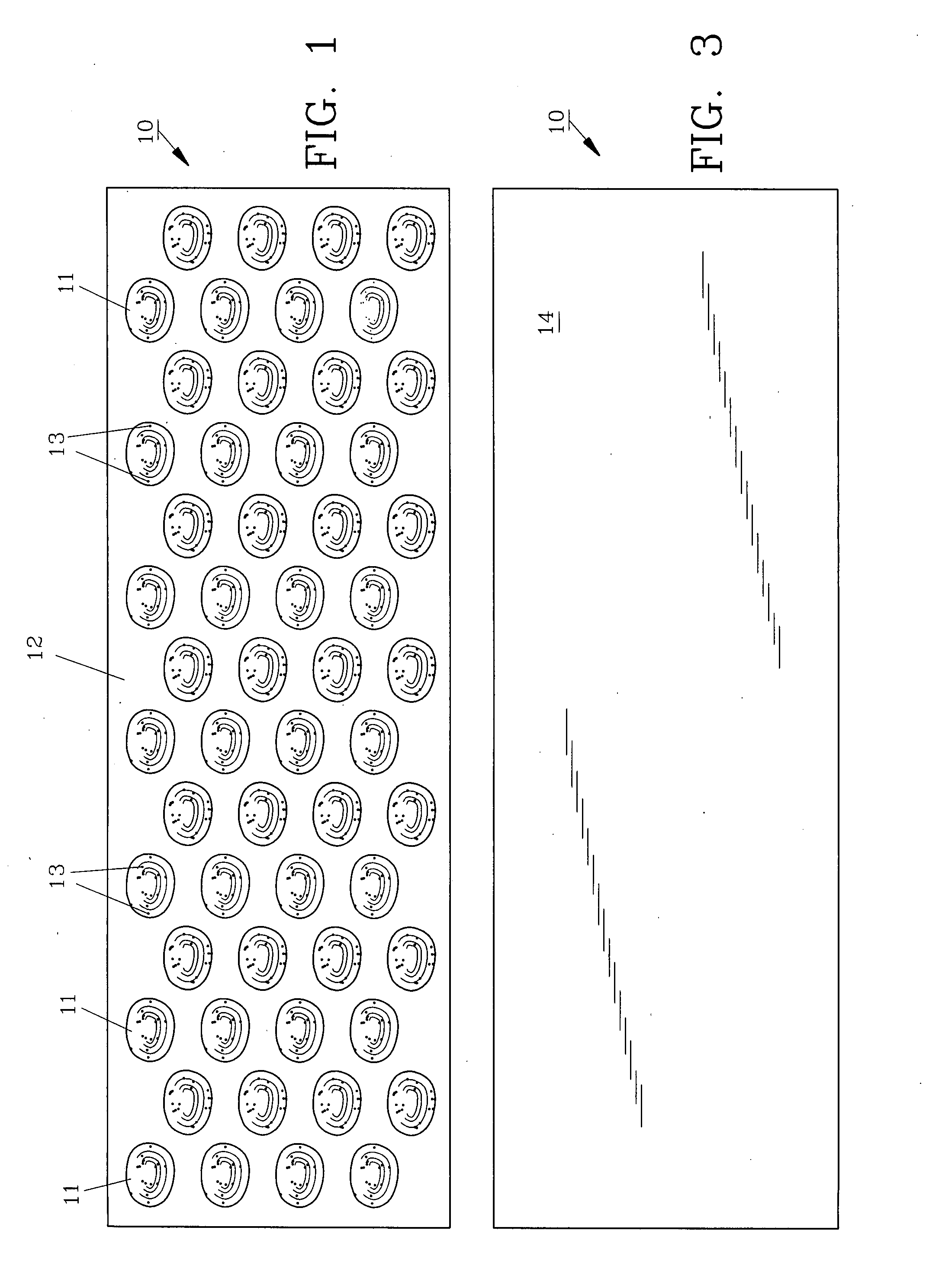

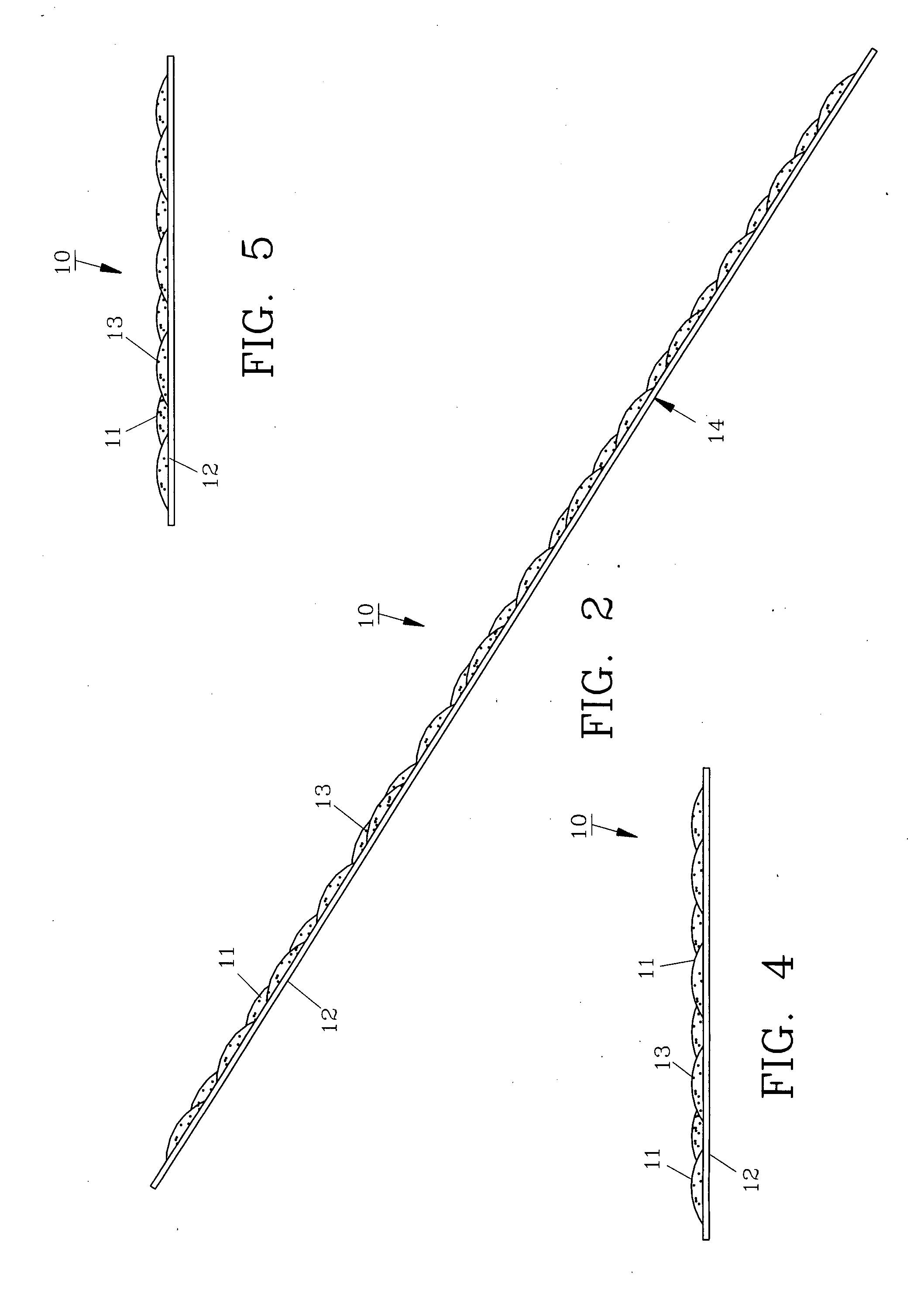

[0022]For a better understanding of the invention and its operation, turning now to the drawings, FIGS. 1-9 show preferred pavement marker 10 in various views. Pavement marker 10 is formed from a conventional thermoplastic material as used for other standard pavement markers and has an overall thickness of approximately 0.10 inches (0.254 cm) to approximately 0.25 inches (0.635 cm), a length of three (3) feet (91.4 cm) and a width of twelve (12) inches (30.5 cm) although various sizes can be made to accommodate specific applications. Pavement marker 10 can be made for example two (2) feet (61 cm) to three (3) feet (91.4 cm) in length and four to twenty-four (4-24) inches (10-61 cm) in width. Pavement marker 10 can also be made in roll form with a typical length of thirty (30) feet (9.15 m). The thickness of 0.10 inches (0.254 cm) to 0.25 inches (0.635 cm) can also vary as required with the exact size dependent on the particular needs of the user.

[0023]As shown in FIG. 1, pavement ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com