Shaft-Like Parts Feeding Apparatus

a technology of shaft-like parts and feeding apparatus, which is applied in the direction of conveyor parts, manufacturing tools, transportation and packaging, etc., can solve the problems of excessively long parts, excessively long parts that are already removed, and excessively long parts that are detected in excessively long parts, so as to reduce the tilt of the shaft-like part, reduce the amount of shaft-like parts, and reduce the effect of hydrodynamic pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0101]First, a first embodiment will be described.

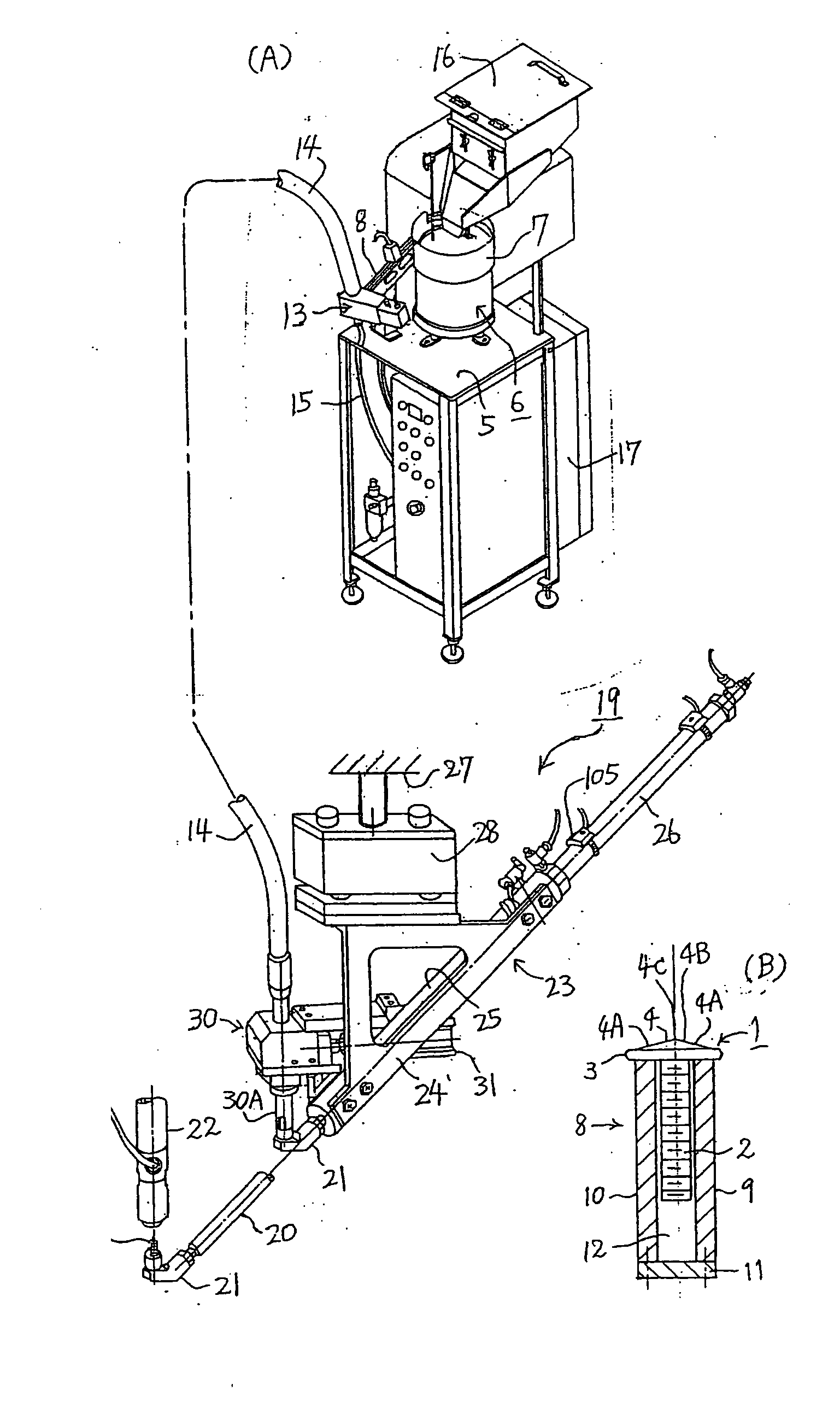

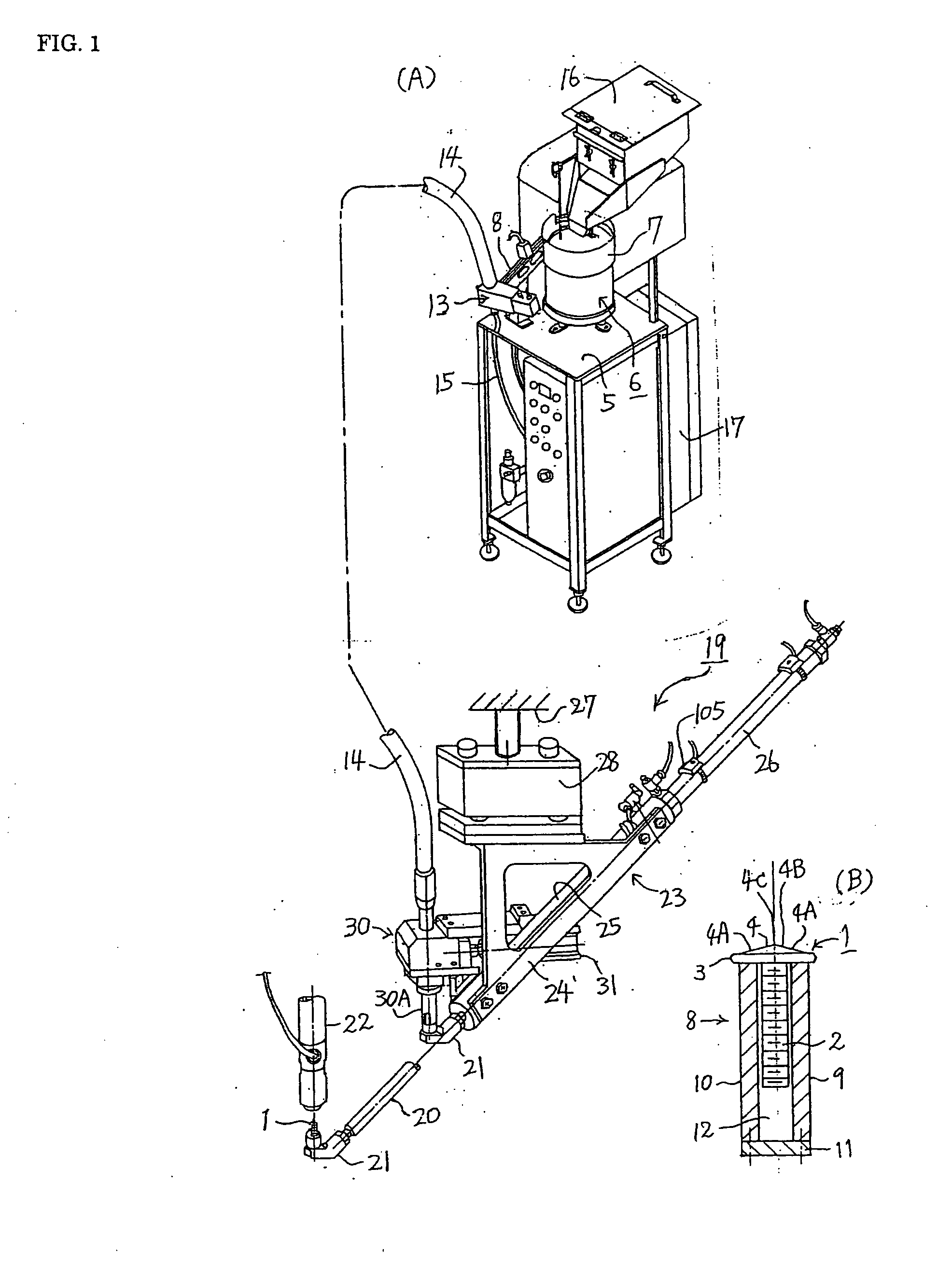

[0102]A shaft-like part in this first embodiment is a projection bolt made of iron, as shown in FIG. 1 (B). The projection bolt 1 comprises a shank 2 formed with a male thread, a circular flange 3 integral with the shank 2, and a welding projection 4 formed on the flange 3. The projection bolt will sometimes be referred to simply as a bolt.

[0103]The flange 3 is the maximum outer diameter portion of the bolt 1.

[0104]And, the welding projection 4 is formed by a tapered section 4B consisting of a gentle slope surface 4A, the tapered section 4B being concentric with the flange 3 and having a sharp-pointed apex C formed in the middle.

[0105]FIG. 1 (A) is a perspective view of the apparatus in its entirety.

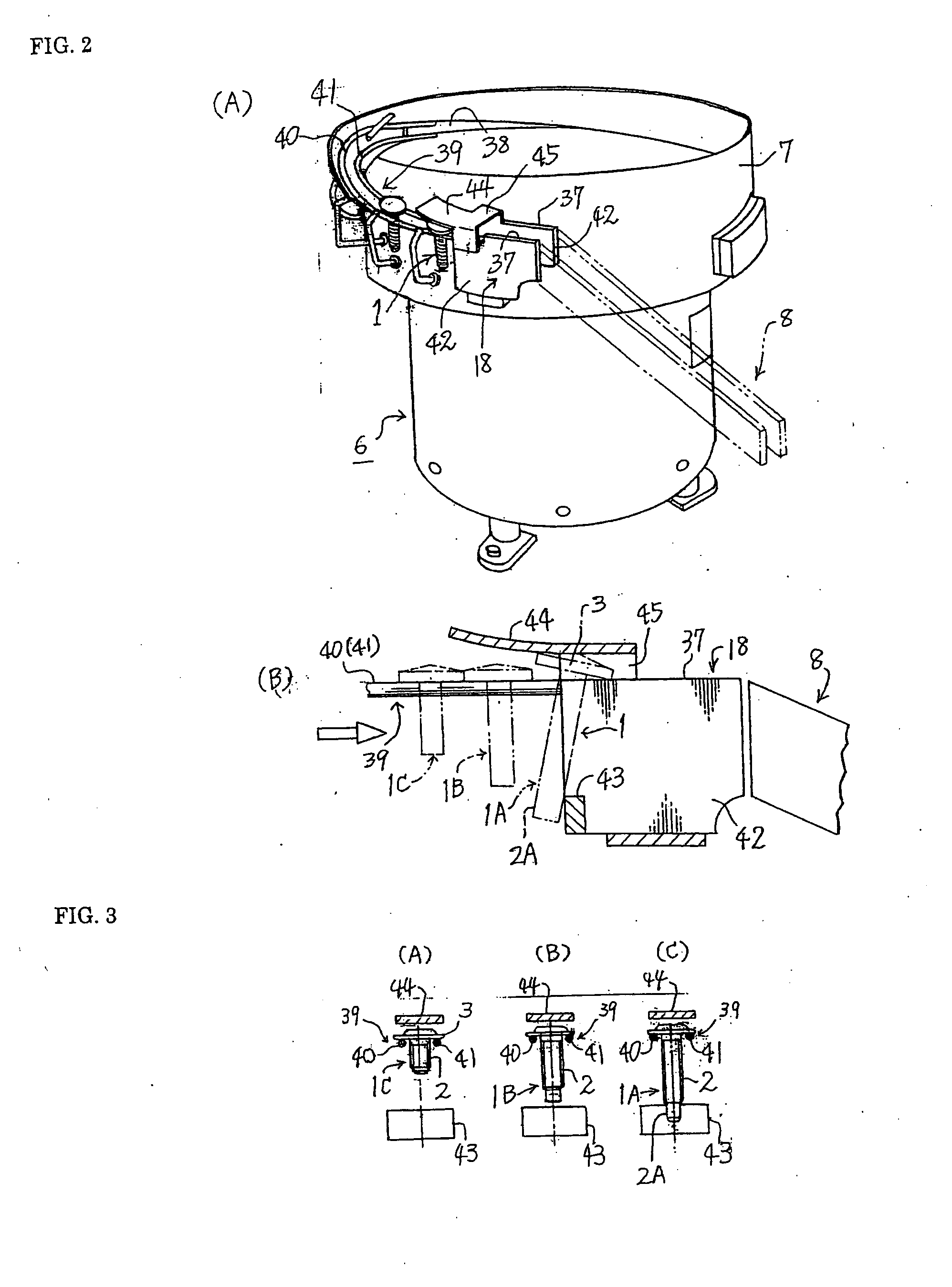

[0106]First, the structure of a parts feeder and peripherals will be described.

[0107]A parts feeder 6 is fixed on a stand 5 which is a stationary member. As this parts feeder 6, various types are employed, including one in which parts are...

second embodiment

[0188]Next, a second embodiment will be described with reference to FIG. 8.

[0189]In this second embodiment, a function of detecting normal bolts 1B is imparted to the movable electrode 22 in the first embodiment described above.

[0190]The movable electrode 22 circular in cross section has an end member 74 integrated with a cylindrical electrode main body 73 by a threaded section 75. This end member 7 is substantially in the form of a cylinder, with an insulation cylinder 78 attached to the inside thereof as by adhesion. Further, a joint section 77 is integrated with the upper end of the electrode main body 73 through a threaded section 76. The electrode main body 73 also has an insulation cylinder 79 fitted therein, with a large diameter hole 80 and a small diameter hole 81 formed therein. The two insulation cylinders 78 and 79 are made of insulating synthetic resin such as polypropylene or polyamide resin.

[0191]A heat insulation member 82 slidably fitted in the insulation cylinder 7...

third embodiment

[0212]Next, a third embodiment will be described with reference to FIG. 9.

[0213]The structure of the holding head 21 and control of the spouting of compressed air will be described in detail with reference to FIG. 9.

[0214]Although the welding projection 4 of a projection bolt 1 is not indicated by the reference characters 4A, 4B, 4C in FIG. 9 (A), it is formed by a tapered section 4B consisting of a gentle slope 4A, as described with reference to FIG. 1 (B), the tapered section 4B being concentric with the flange 3 and being centrally formed with a pointed top 4C (see FIG. 9 (C).

[0215]A minute air gap T1 is defined between the flange 3 and the inner peripheral surface of a tapered hole 32A facing the outer peripheral surface of the flange 3.

[0216]FIG. 9 (B) is a top view of the holding head 21, showing that the air opening 33, permanent magnet 29, and tapered hole 32A are circular.

[0217]As shown in FIG. 9 (C), the opening in the air opening 33 is made in the form of an annular suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| taper angle | aaaaa | aaaaa |

| taper angle | aaaaa | aaaaa |

| taper angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com