Pump

a technology of pump and seal, applied in the field of pumps, can solve the problems of water leakage through the shaft seal portion, insufficient flow resistance, and time-consuming adjustment of the gap, and achieve the effect of enhancing pump efficiency, sufficient flow resistance, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

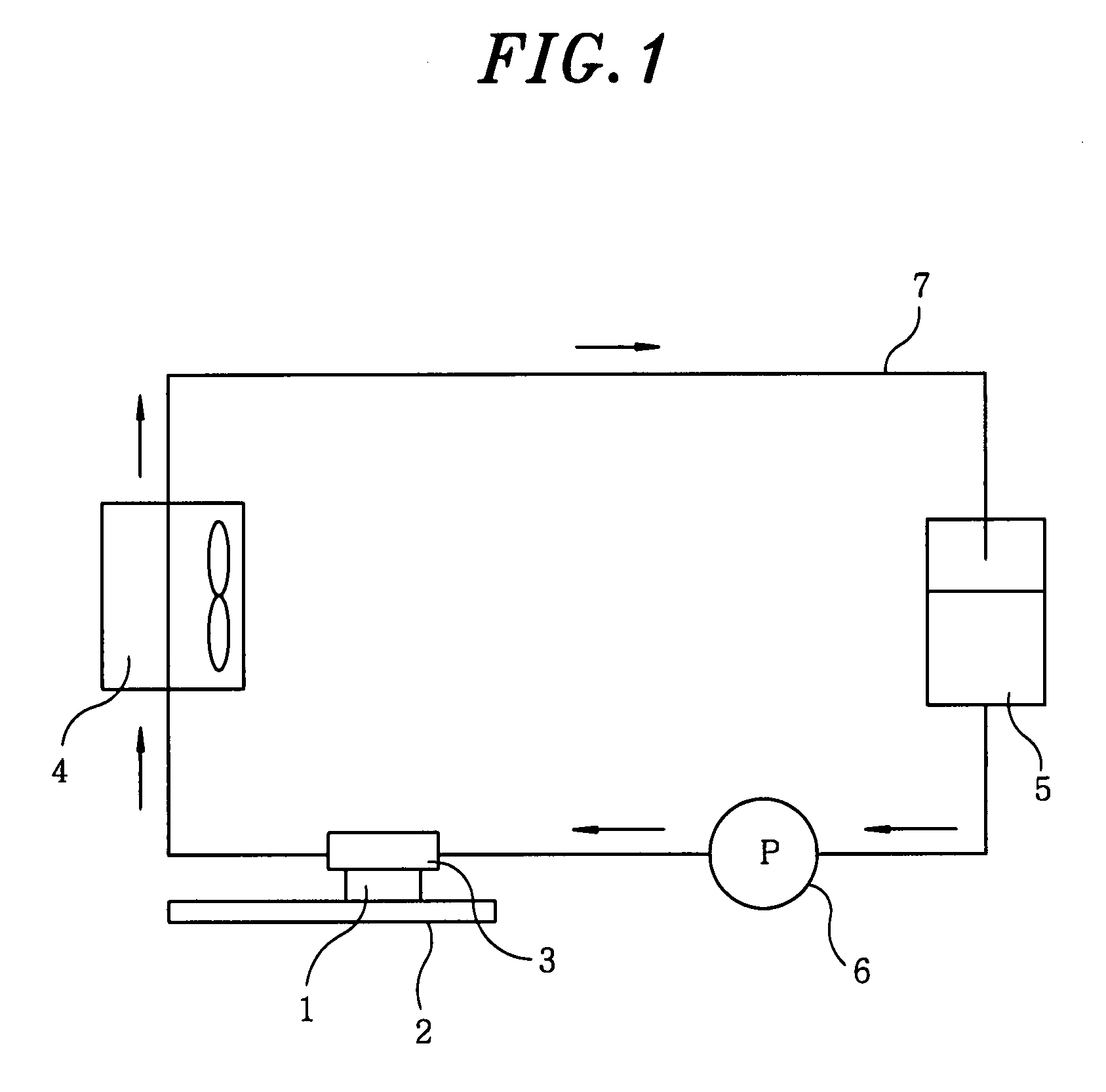

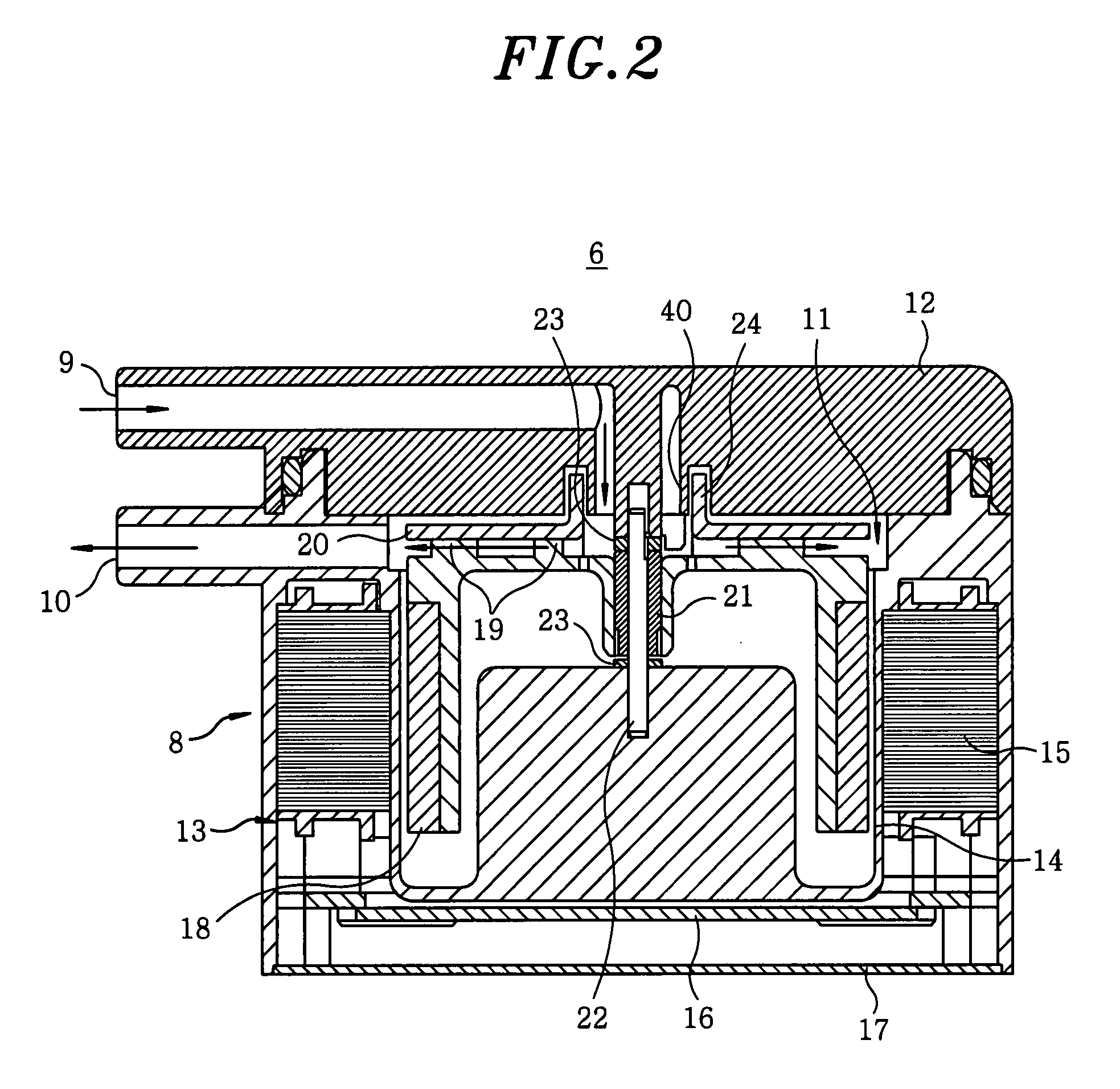

[0027]Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings, which forms a part hereof.

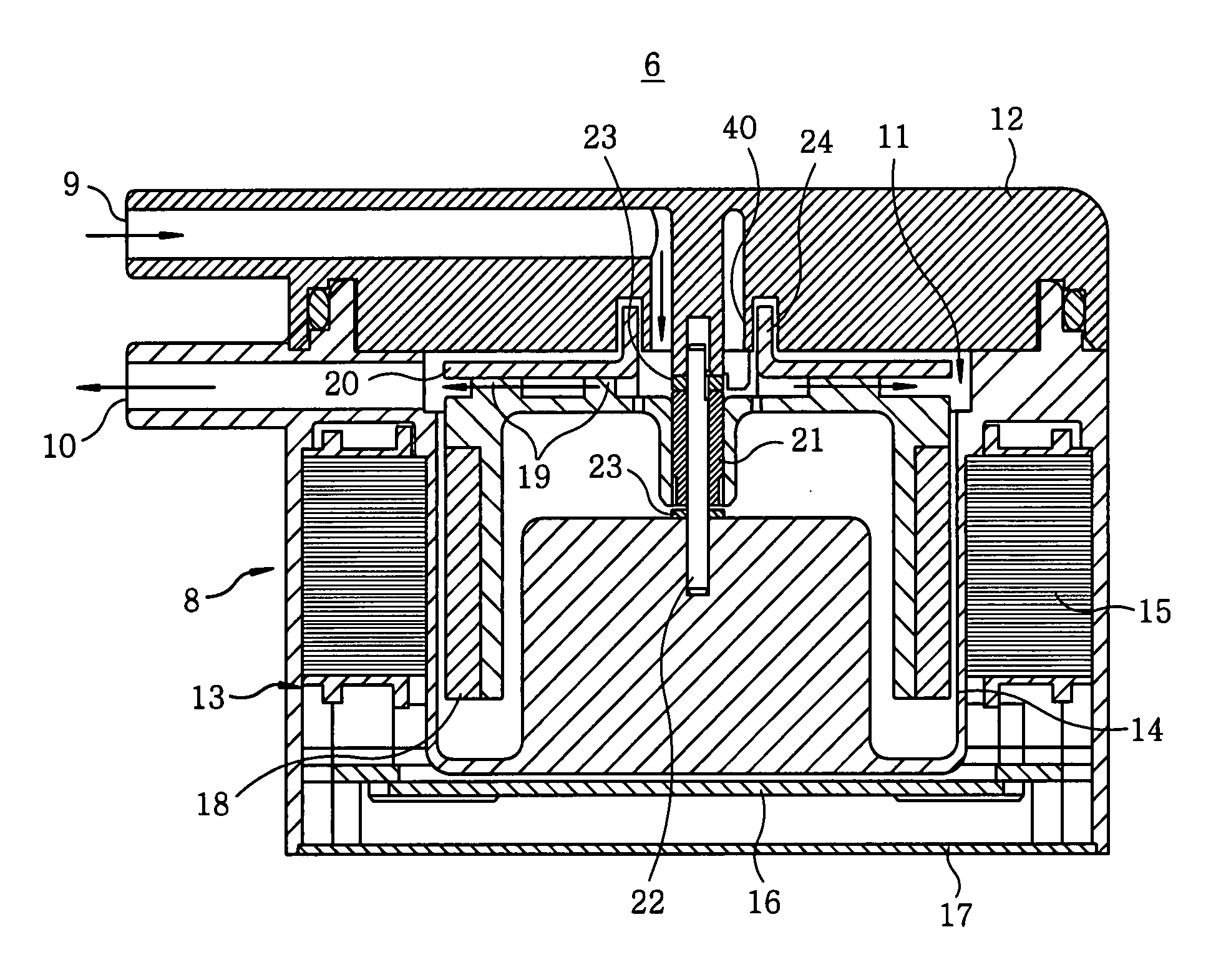

[0028]As shown in FIG. 1, a coolant circulation system includes a heat generation element 1 installed on a substrate 2; and a heat sink unit 3 such as a heat spreader, for cooling the heat generation element 1 by performing a heat exchange with the heat generation element 1 using a coolant (e.g., water).

[0029]The coolant circulation system further includes a radiator 4 for taking heat from the coolant; a reservoir tank 5 for storing the coolant therein; a pump for circulating the coolant; and a pipeline 7 connecting the heat sink unit 3, the radiator 4, the reservoir tank 5 and the pump 6.

[0030]The coolant in the reservoir tank 5 is discharged from the pump 6 to flow into the heat sink unit 3 via the pipeline 7. In the heat sink unit 4, heat is transferred from the heat generation element 1 to the coolant, whereby the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com