Method for making an optical preform

a manufacturing method and optical taper technology, applied in glass production, glass making equipment, manufacturing tools, etc., can solve problems such as optical taper, and achieve the effects of reducing the stress that is built into the deposited glass layers during the vapor deposition process, and increasing the usable preform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

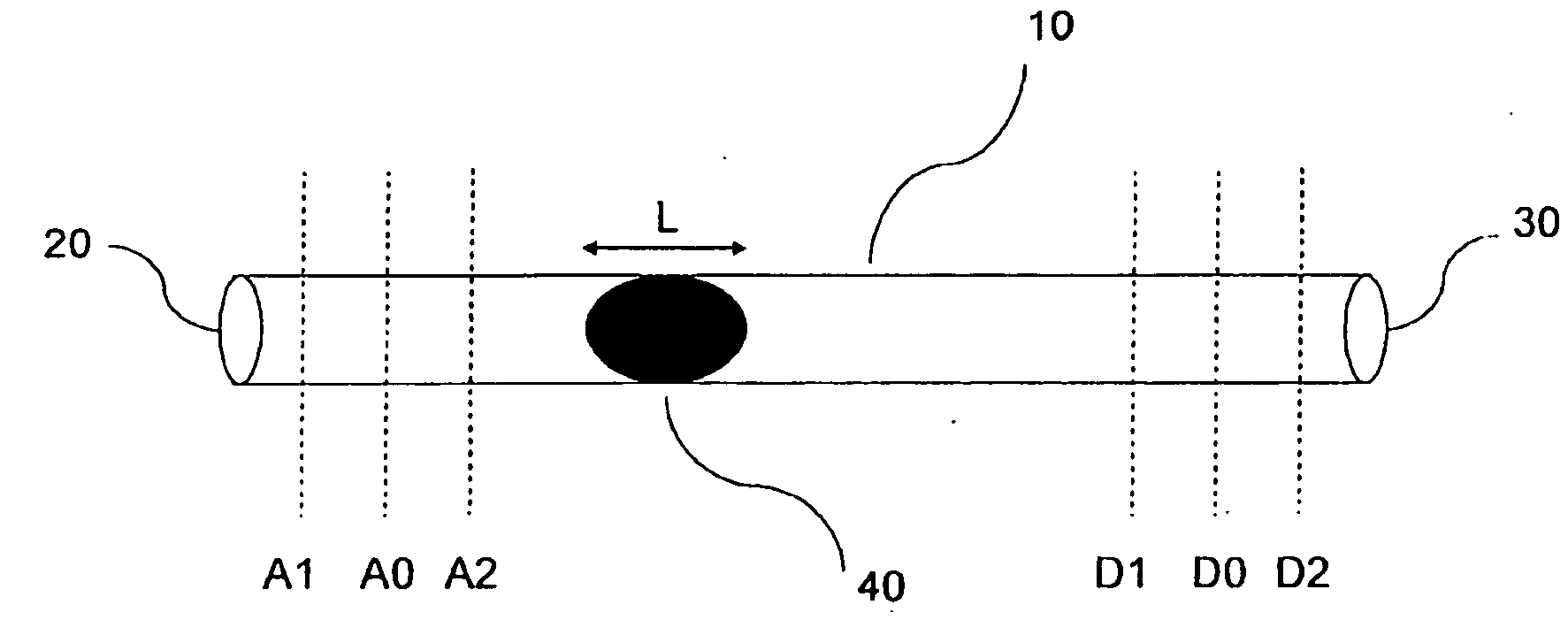

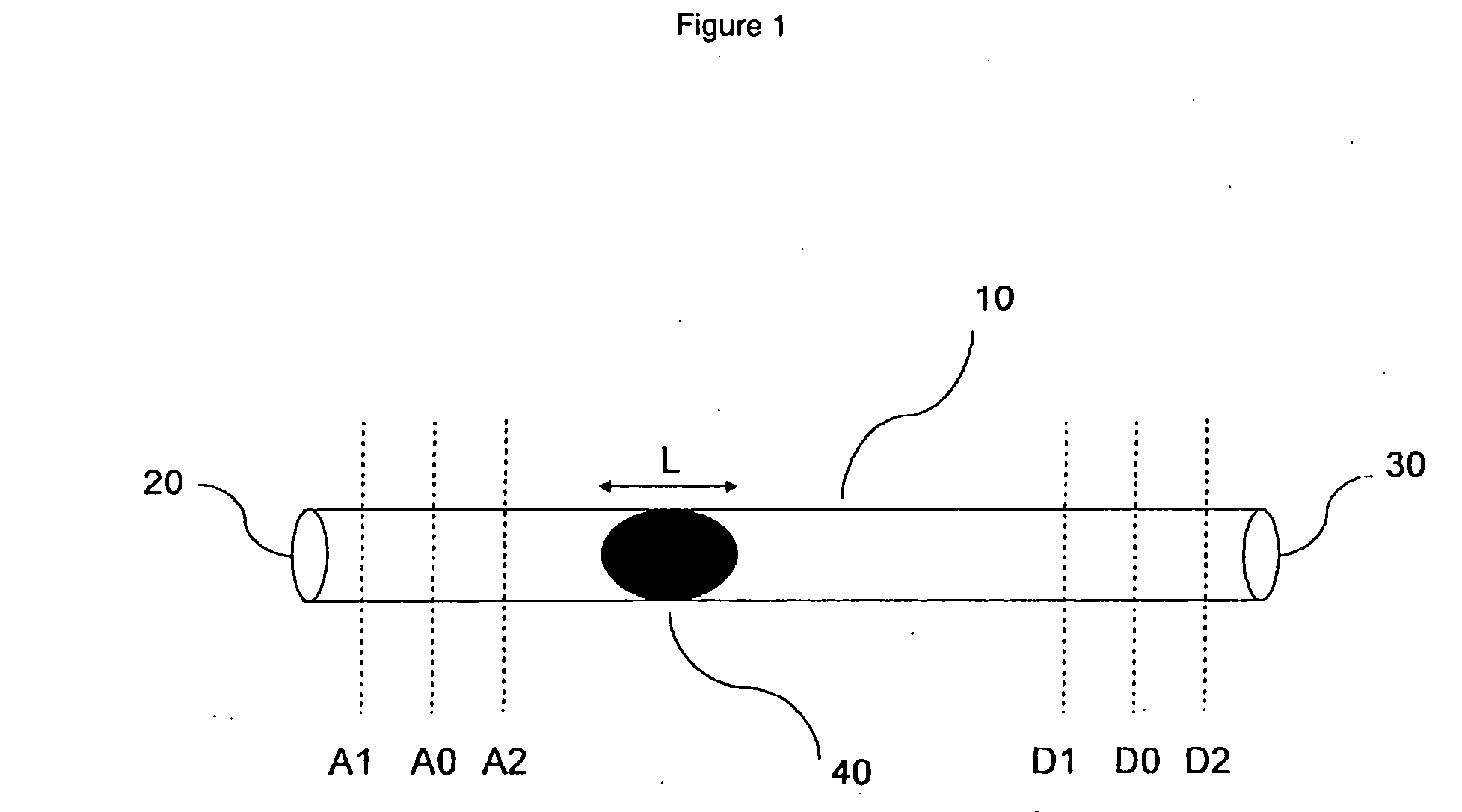

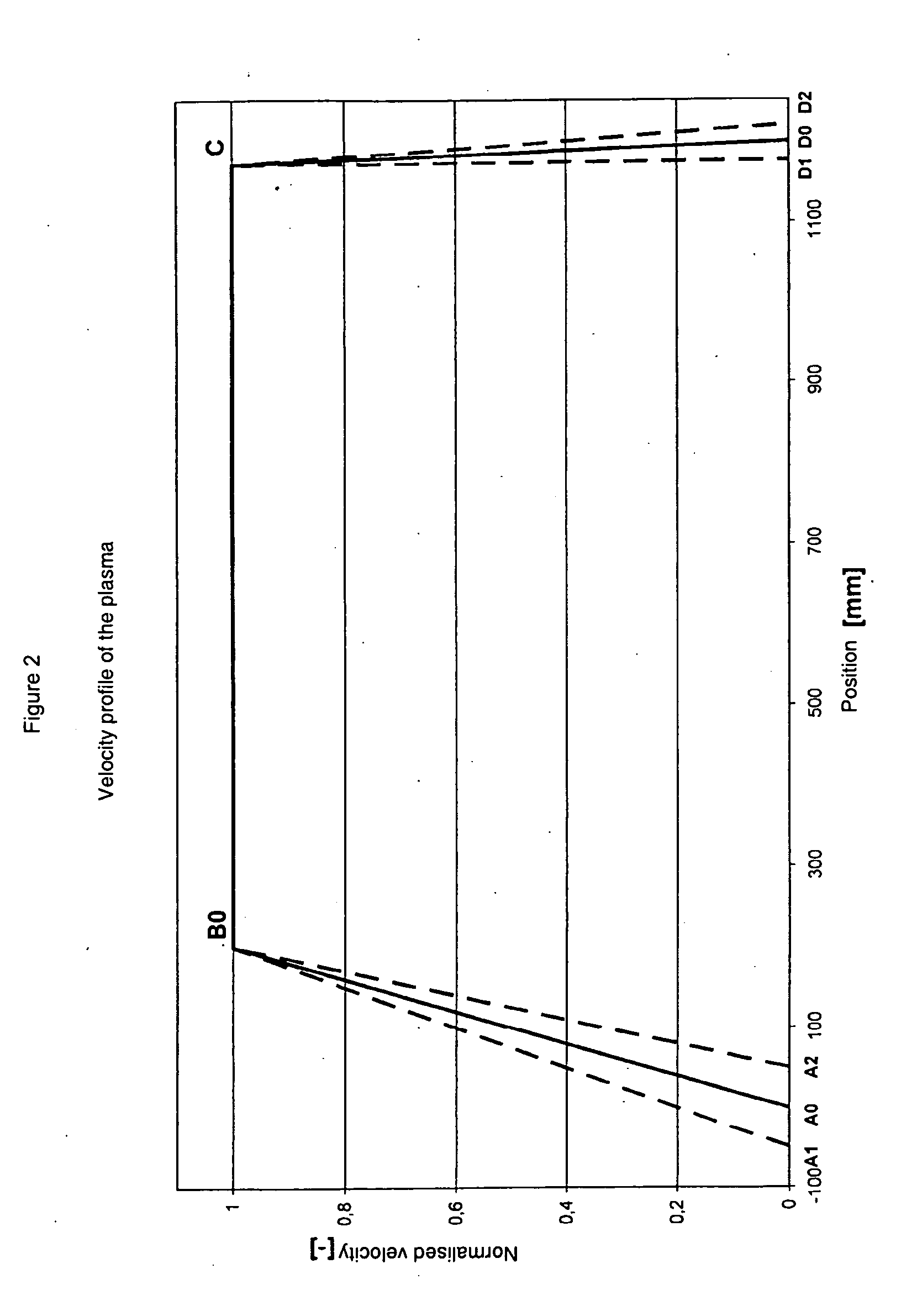

[0060]Preforms for forming optical fibers having a radial refractive index profile as shown in FIG. 4 are manufactured via the method according to the present invention. The reversal point near the supply side shifts in the direction away from the discharge side during the entire step (iii). In FIGS. 1 and 2, this means that the reversal point near the supply side shifts from A0 to A1 during step (iii). The plasma length L is about 200 millimeters, and the shift takes place linearly with time. The total shift is varied, and the effect thereof on the usable preform length is determined.

TABLE 1exampletotal shift (mm)usable preform length (mm)No shift01000I201010II501030III701050IV1001050V110980

[0061]It has been observed that preforms manufactured according to the present invention exhibit a reduction of about five percent with respect to layer cracking. By way of example, such a five percent reduction might represent an improvement in the incidence of layer cracking from seven percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com