Cavitation-deterring energy-efficient fluid pump system and method of operation

a fluid pump and energy-saving technology, applied in the direction of positive displacement liquid engines, auxilaria, machines/engines, etc., can solve the problems of increased displacement pumps generally suffering from reduced cavitation speeds, application often represents significant challenges, and the arrangement is much more costly and space-consuming. , to achieve the effect of increasing the fluid pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

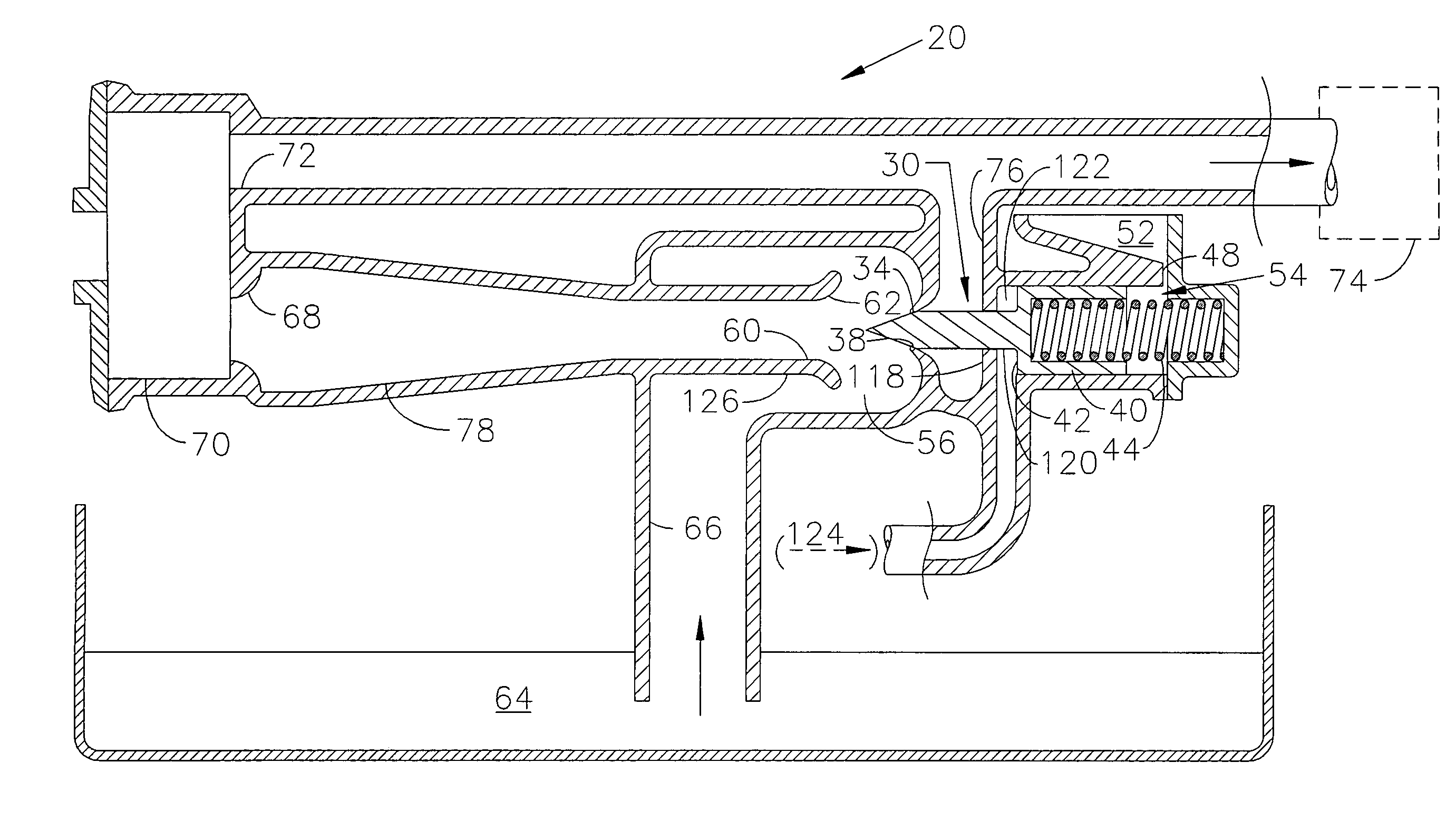

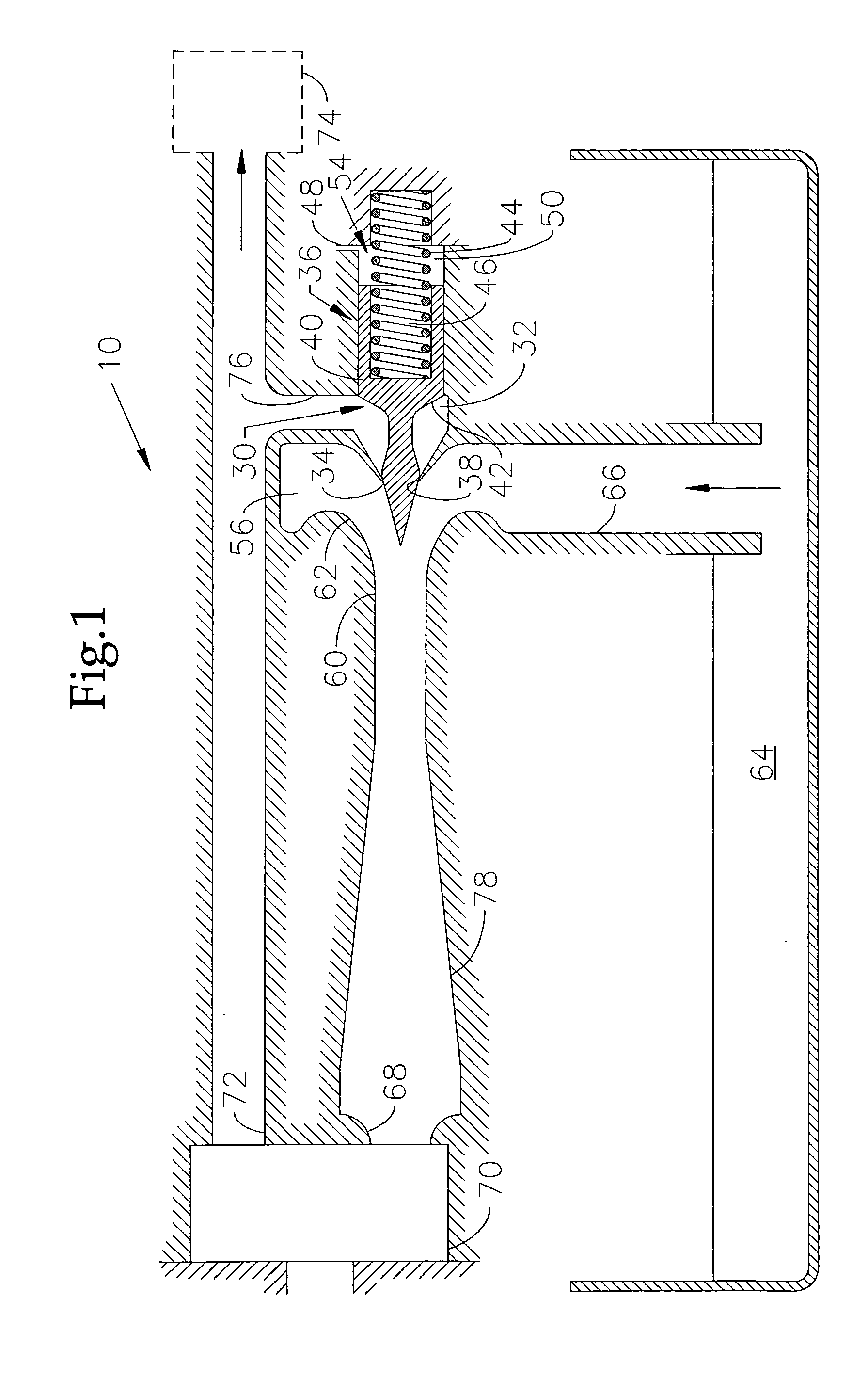

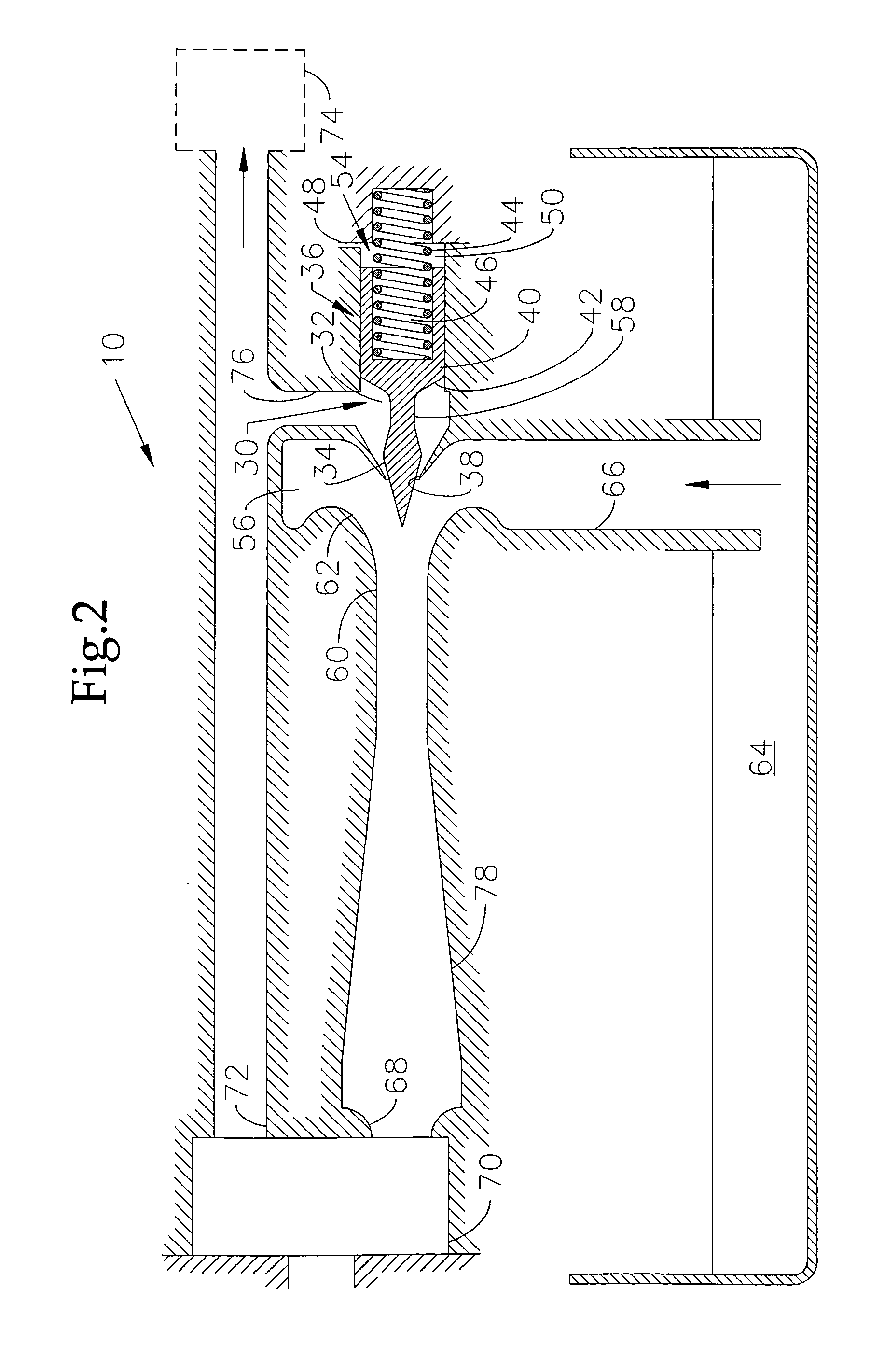

[0029]Adjustable nozzle jet pumps are known for substantially extended efficiency range in comparison with fixed nozzle area jet pumps. In the exemplary embodiment, a consistently high velocity of nozzle exit flow enables an automatically-adjusted variable nozzle area jet pump to provide this performance advantage more or less continually in the case of variable operating conditions. Substantial further efficiency range advantages are gained over fixed area ratio jet pump-assisted positive displacement pumping systems by means of the exemplary embodiment's low cost, compact integration of normally non-passing pressure control valve functionality with an adjustable nozzle-type jet pump.

[0030]The exemplary embodiment utilizes this simple normally non-passing pressure-controlling adjustable nozzle jet pump valve (hereafter referred to as a “Jet Pump Valve” or “JPV”) to captively recirculate unused flow volumes back to a positive displacement pump's inlet with pressure boost (or reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com