Mechanically sealable rapid opening stagger-flush residential toilet

a toilet and rapid opening technology, applied in the direction of flushing devices, water installations, constructions, etc., can solve the problems of corroded parts of the inside of the bowl, the corroded parts of the waste passageway, and the water evaporates,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

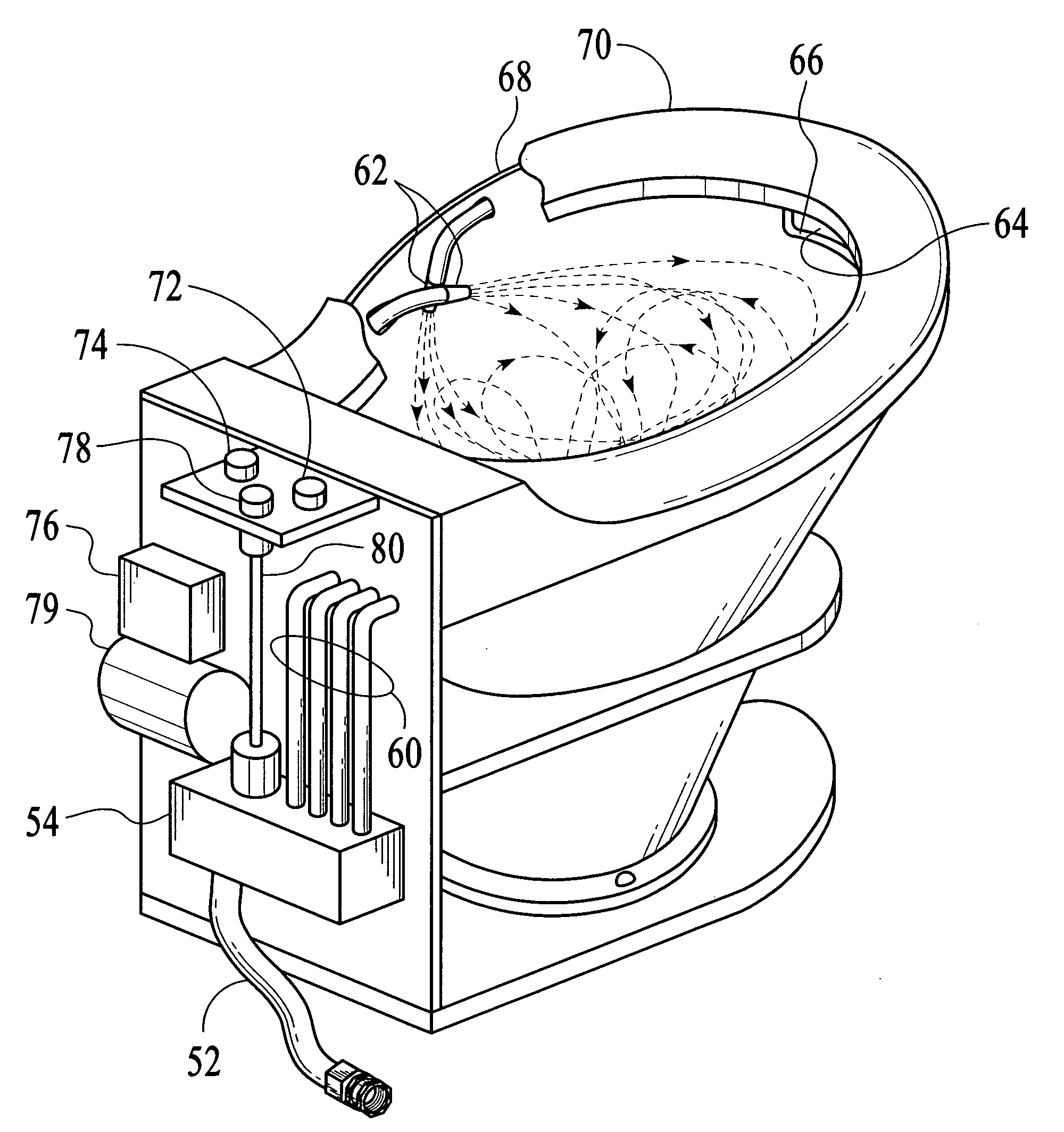

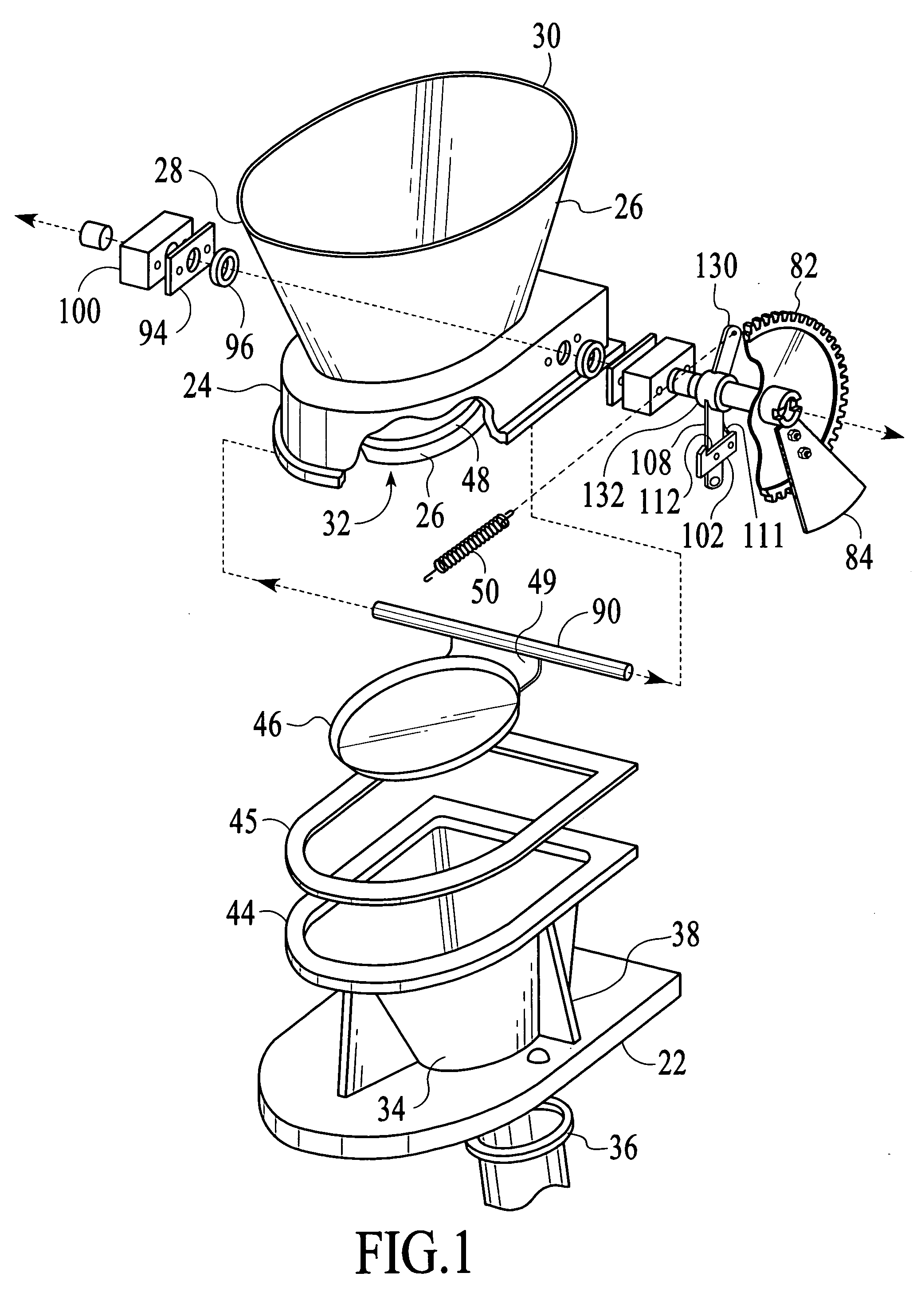

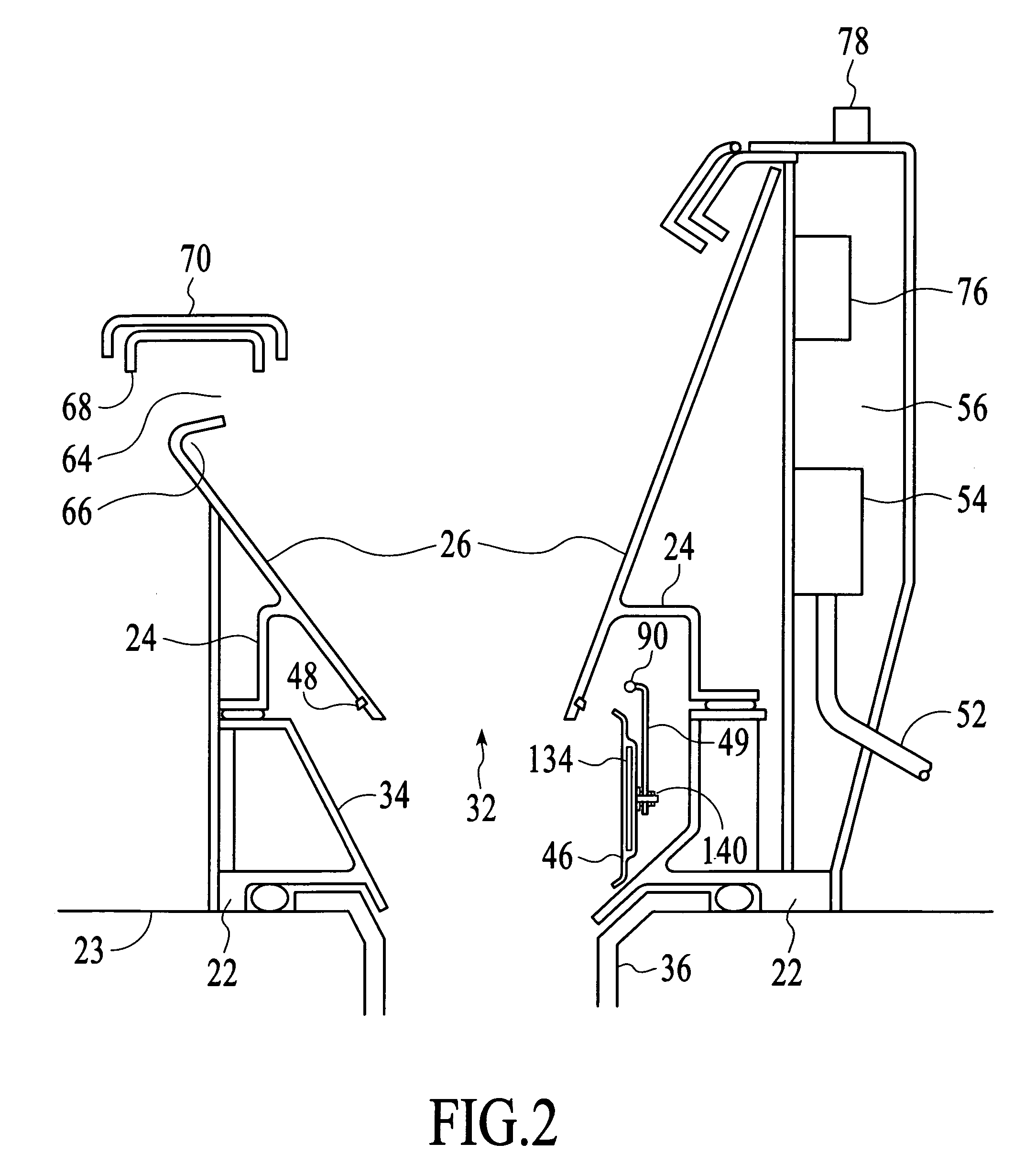

Structures And Connections—FIG. 1

[0138]As shown in FIG. 1, a mechanical-trap toilet according to a first embodiment comprises a lower structure 22 that supports the toilet. The lower support structure sits on a bathroom floor 23 and is connected to a conventional adjoining drain line 36.

[0139]A gasket 45 is sandwiched between an upper support structure 24 and a flange 44 of a waste passageway 34. The waste passageway is an integral part of the lower structure

[0140]A bowl 26 is an integral part of the upper support structure. The bowl has a frustum shape. It resembles an inverted cone that lacks an apex.

[0141]The bowl has a bottom outlet 32. A sealing ring 48 is press fitted into a groove that surrounds an outside part of the bowl above the bottom outlet. Reinforcing ribs 38 help support the waste passageway, the bowl, and lower support structure 22.

[0142]A saucer-pivoting shaft 90 extends from the right and left sides of upper support structure 24. The saucer-pivoting shaft is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com