Burner assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

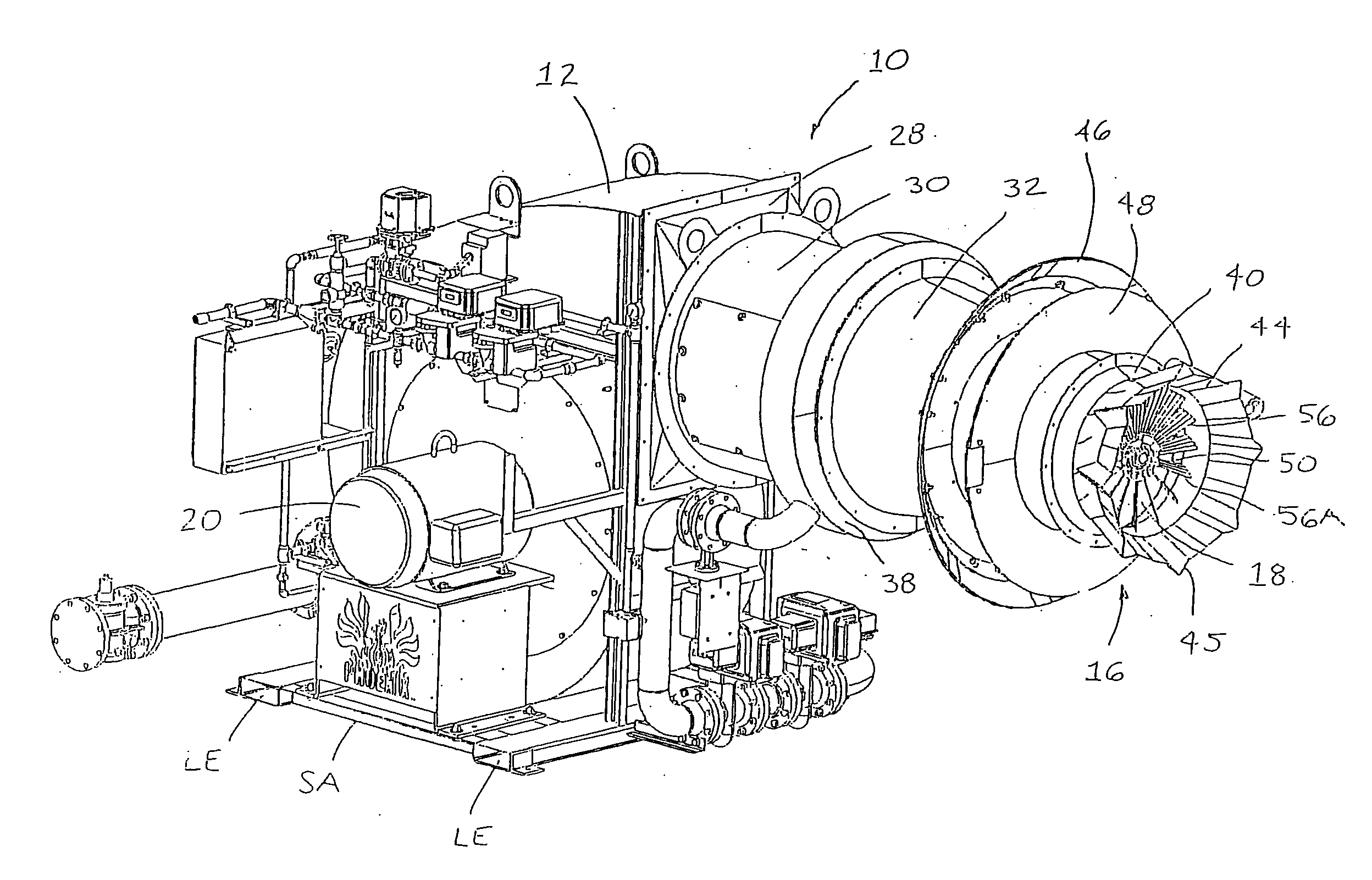

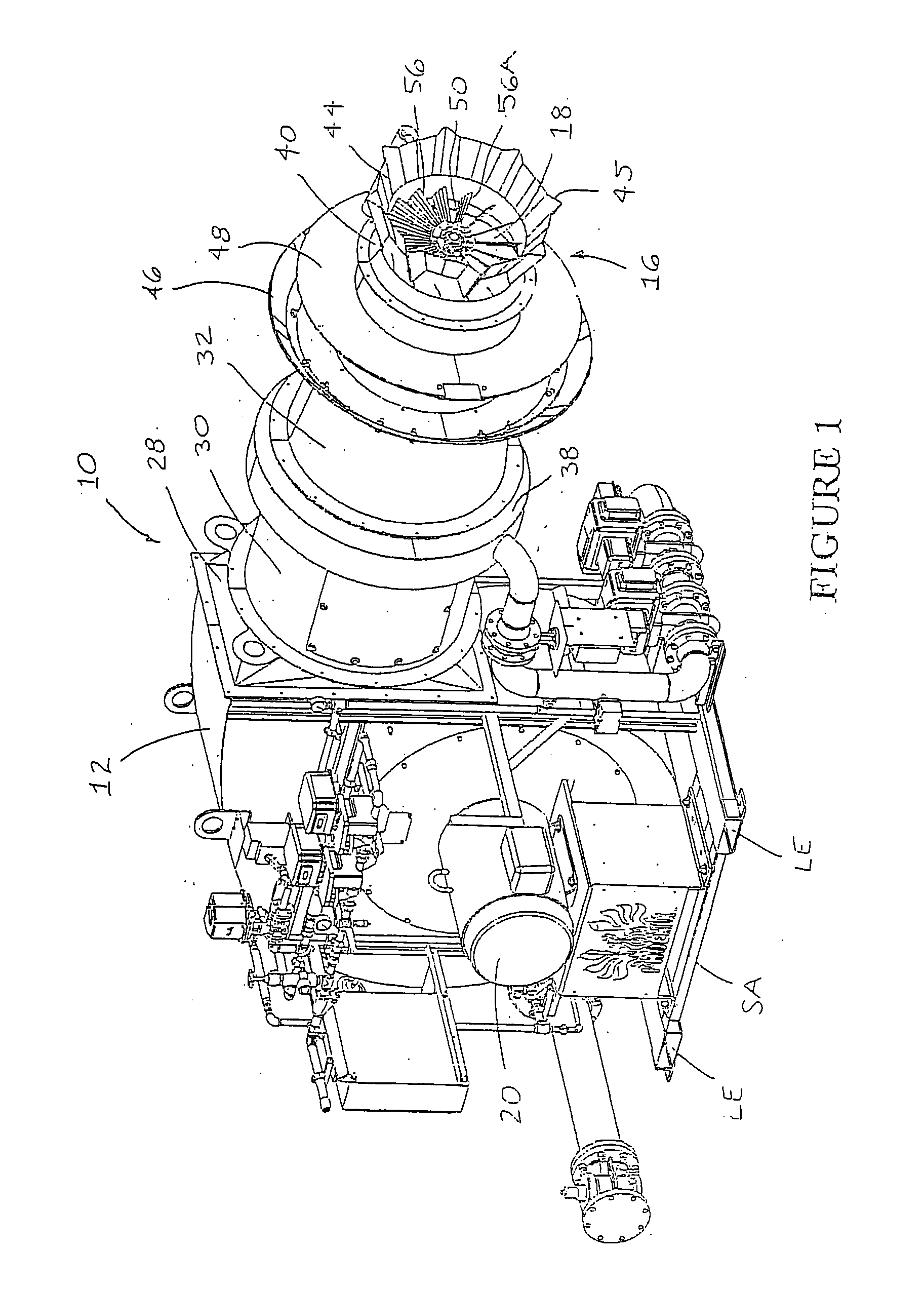

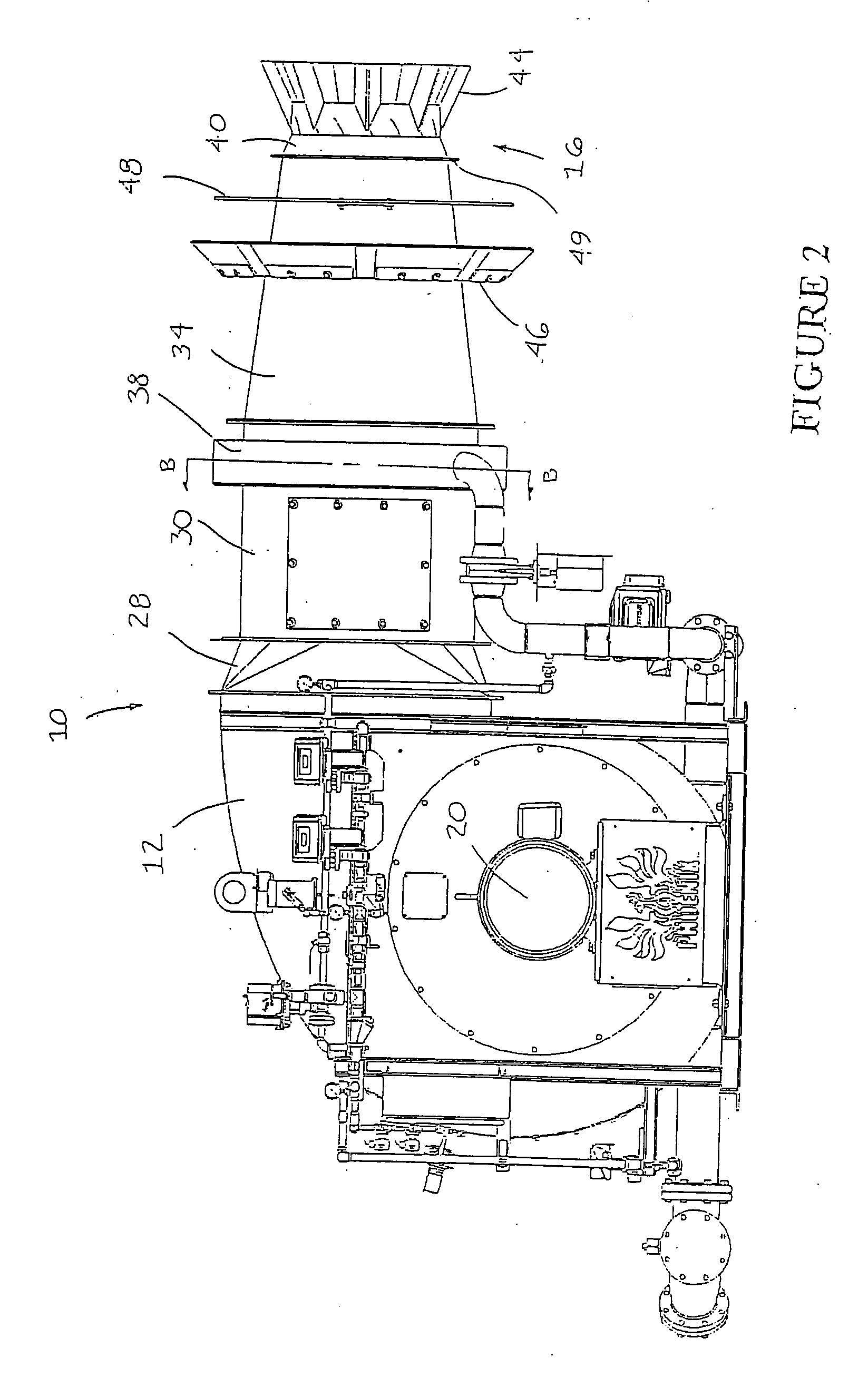

[0005]Accordingly, it is an advantage of the preferred embodiments of the invention described and claimed herein to provide an apparatus capable of selectively firing on gaseous fuel, liquid fuel, or both gaseous and liquid fuel. It is also an advantage of the preferred embodiments of the invention described and claimed herein to provide an apparatus capable of firing on gaseous and / or liquid fuels without physically altering the components of the apparatus, changing the firing rate of the apparatus, or shutting down the apparatus. It is a further advantage of the preferred embodiments of the invention described and claimed herein to provide an apparatus adapted to fire on oil or liquid propane without changing the atomizing nozzle. It is another advantage of the preferred embodiments of the invention described and claimed herein to provide an apparatus that is capable of supplying natural gas or propane to the atomizing nozzle for use as pilot fuel. It is also an advantage of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com