Polyester Prepolymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

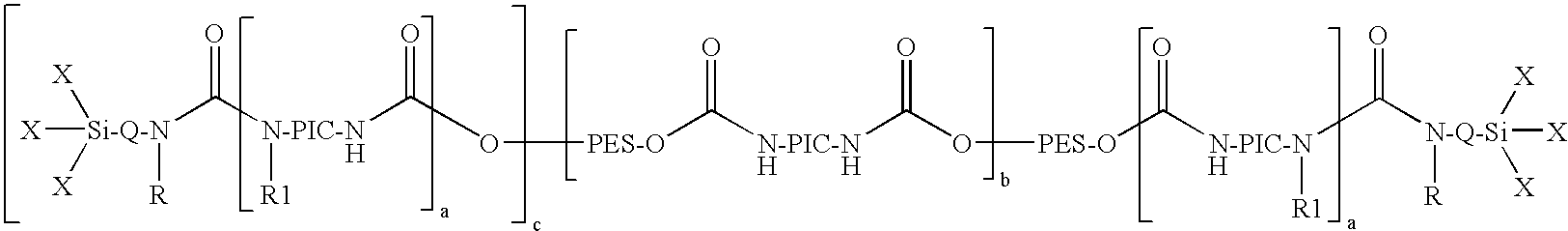

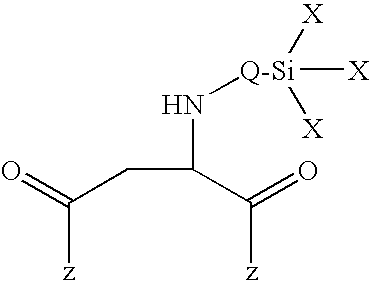

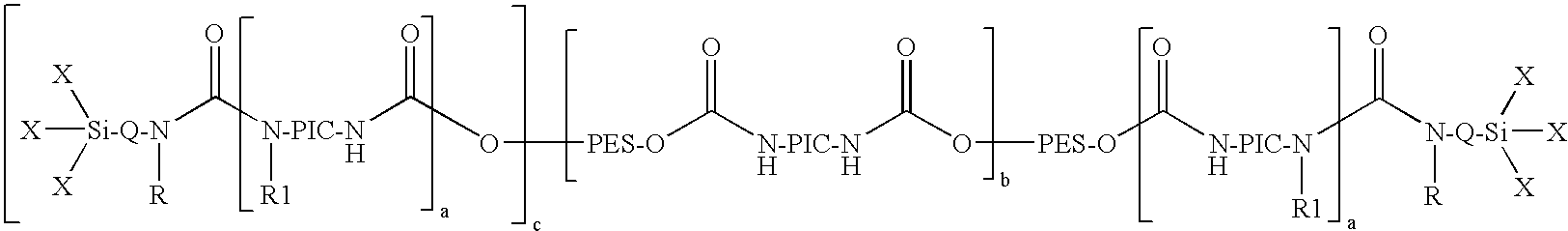

Method used

Image

Examples

example 1 (

According to the Invention)

[0065]In a 5 l sulfonating beaker with a lid, stirrer, thermometer and nitrogen flow, 0.6 g dibutyltin dilaurate (Desmorapid Z®, Bayer MaterialScience AG, Leverkusen, Del.) were added to 2197.92 g of the polyester diol A and the mixture was heated to 60° C. 814.3 g isocyanatopropyltrimethoxysilane (Geniosil® GF40, Wacker AG, Burghausen) were then added dropwise over three hours and stirring was continued until an NCO content could no longer be detected by titration. The alkoxysilyl end group-containing polyurethane prepolymer obtained had a viscosity of 6,450 mPas (23° C.).

example 2 (

According to the Invention)

[0066]In a 10 l reactor with a lid, stirrer, thermometer and nitrogen flow, 0.5 g dibutyltin dilaurate (Desmorapid Z®, Bayer MaterialScience AG, Leverkusen, Del.) were added to 4470.2 g of the polyester diol B and the mixture was heated to 60° C. 529.3 g isocyanatopropyltrimethoxysilane (Geniosil® GF40, Wacker AG, Burghausen) were then added dropwise over half an hour and stirring was continued until an NCO content could no longer be detected by titration. The alkoxysilyl end group-containing polyurethane prepolymer obtained had a viscosity of 90,500 mPas (23° C.).

example 3 (

According to the Invention)

[0067]In a 5 l sulfonating beaker with a lid, stirrer, thermometer and nitrogen flow, 0.2 g dibutyltin dilaurate (Desmorapid® Z, Bayer MaterialScience AG, Leverkusen, Del.) were added to 2387.2 g of the polyester diol A and the mixture was heated to 60° C. Next, 117.6 g hexamethylene diisocyanate (Desmodur H®, Bayer MaterialScience AG, Leverkusen, Del.) were added first over half an hour and 557.1 g isocyanatopropyltrimethoxysilane (Geniosil® GF40, Wacker AG, Burghausen) were then added dropwise over an hour and stirring was continued until an NCO content could no longer be detected by titration. The alkoxysilyl end group-containing polyurethane prepolymer obtained had a viscosity of 25,100 mPas (23° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com