One-piece, continuoulsy blow molded container with rigid fitment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

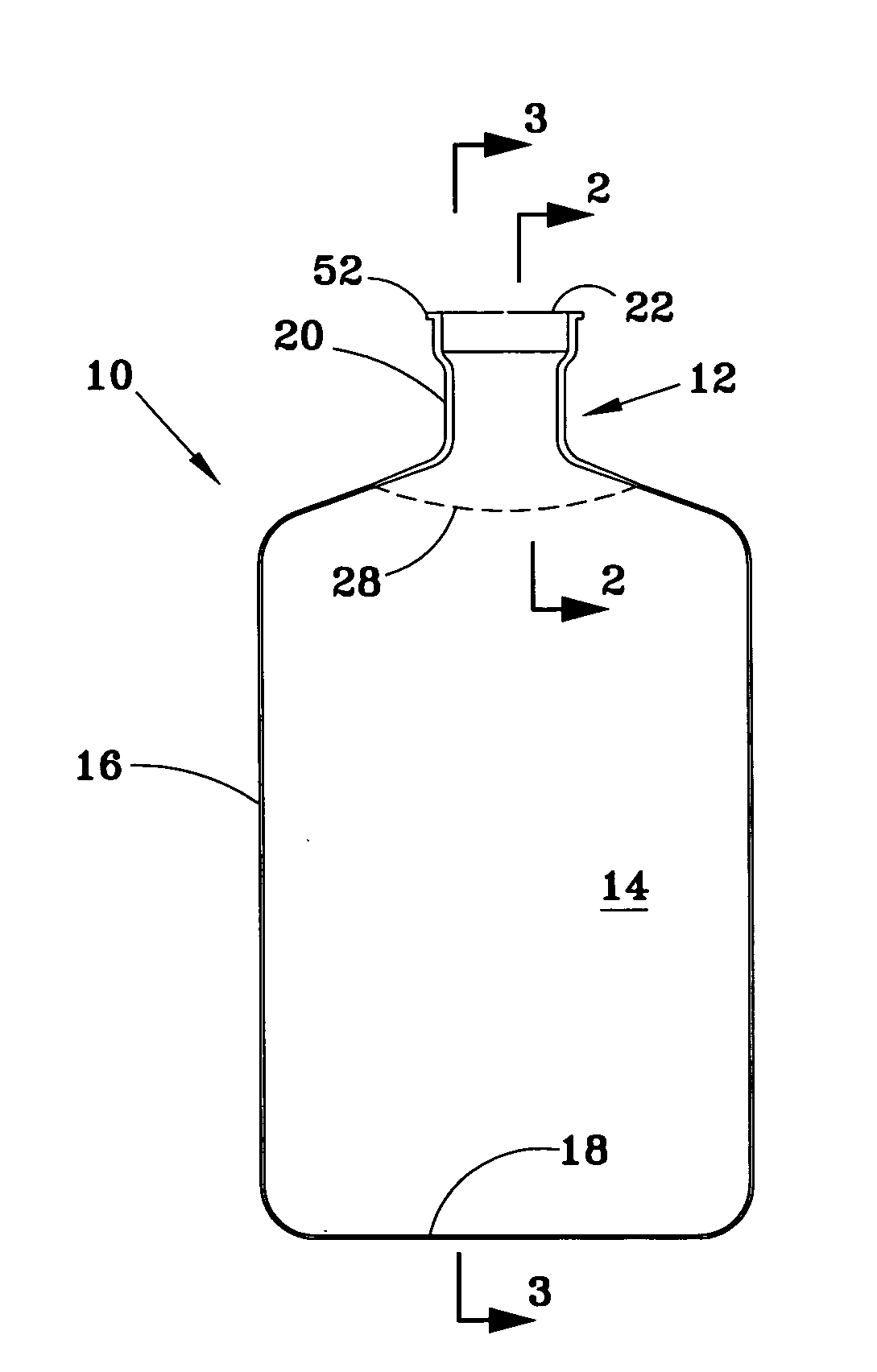

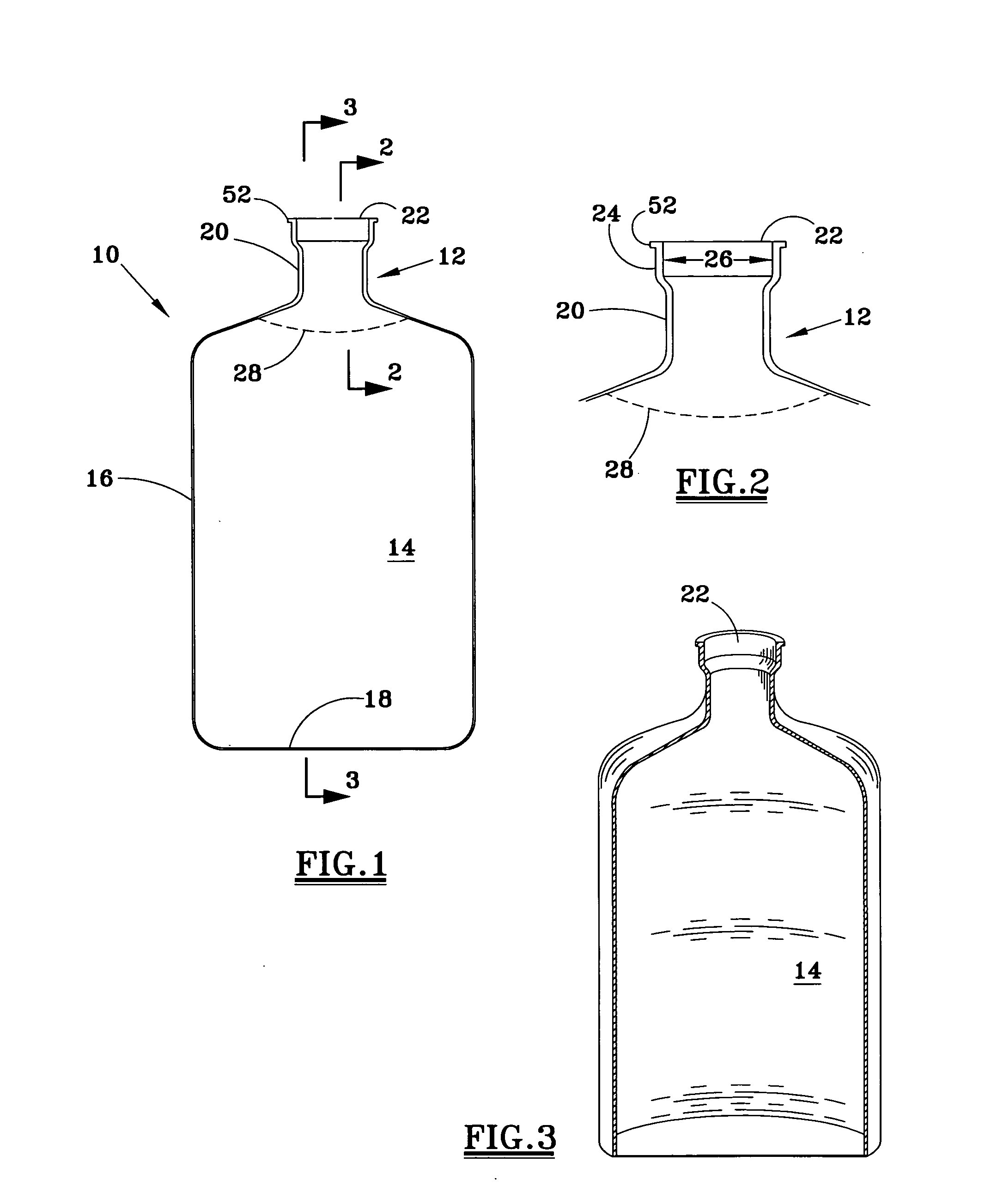

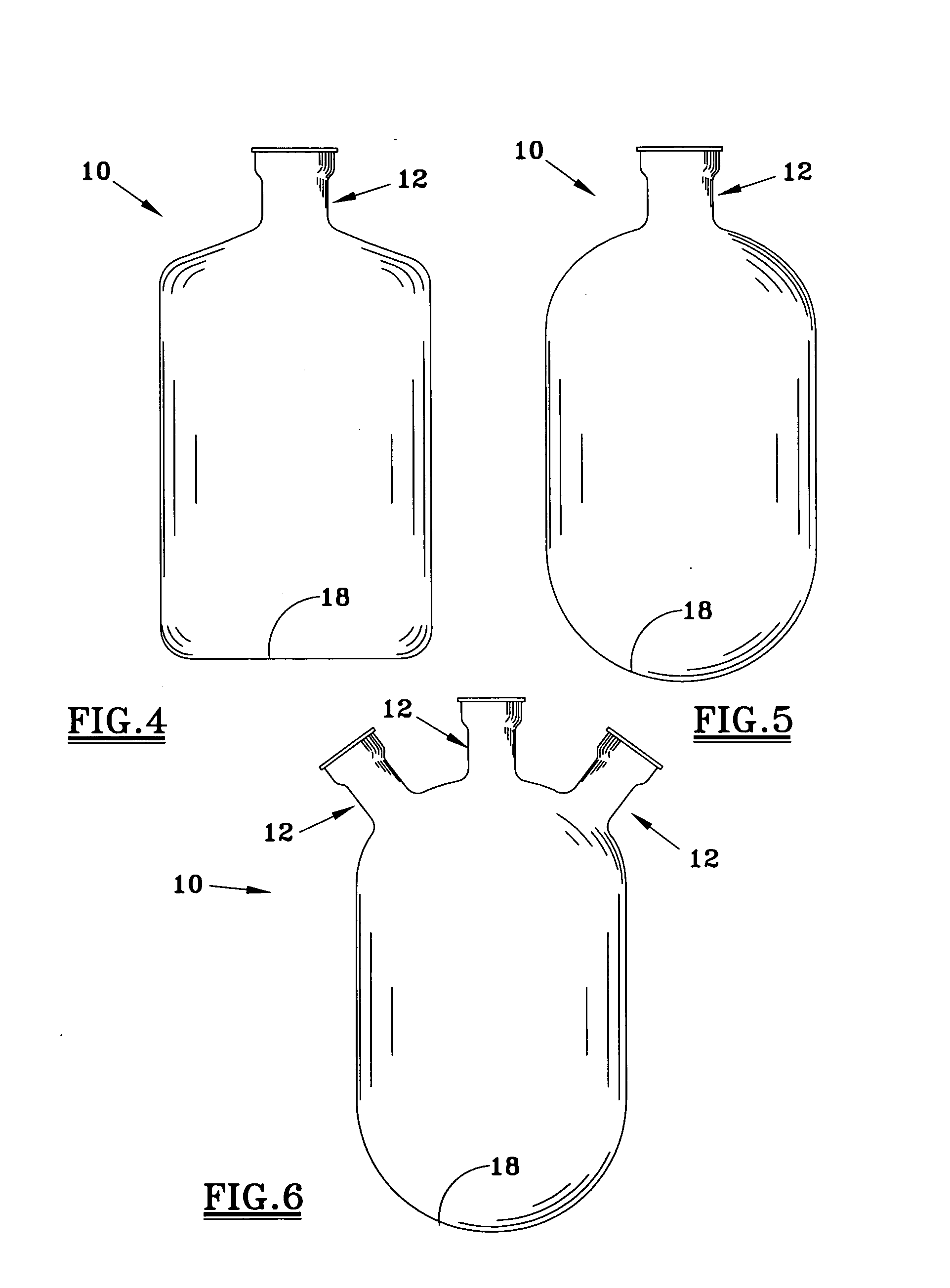

[0030]The present invention one-piece, blow molded container 10 with one or more rigid, thick-walled, fitment 12 and a thin-walled, flexible, film bag portion 14 as depicted in FIGS. 1-6, 9-10 is blow molded from a continuous source of fluoropolymer material, using a single blow molding process, to form the fully integrated, one-piece blow molded container 10 in the absence of any post-molded welds, seams, seals or other mechanical engagement means. The thin-walled, flexible, film bag portion 14 further includes a continuous wall 16 and a bottom portion 18. The bottom portion 18 can selectively be either flat as shown in FIGS. 1 and 4, or can be round as depicted in FIGS. 5 and 6.

[0031]The one or more fitment 12 of the present invention 10, further includes a neck 20 and an orifice 22. The orifice 22 has an outer diameter surface 24 and an inner diameter surface 26. The fitment 12 is blow molded simultaneously with the bag portion 14 as a single piece and the neck 20 is compression ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com