Motor direct drive air pump and related applications thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

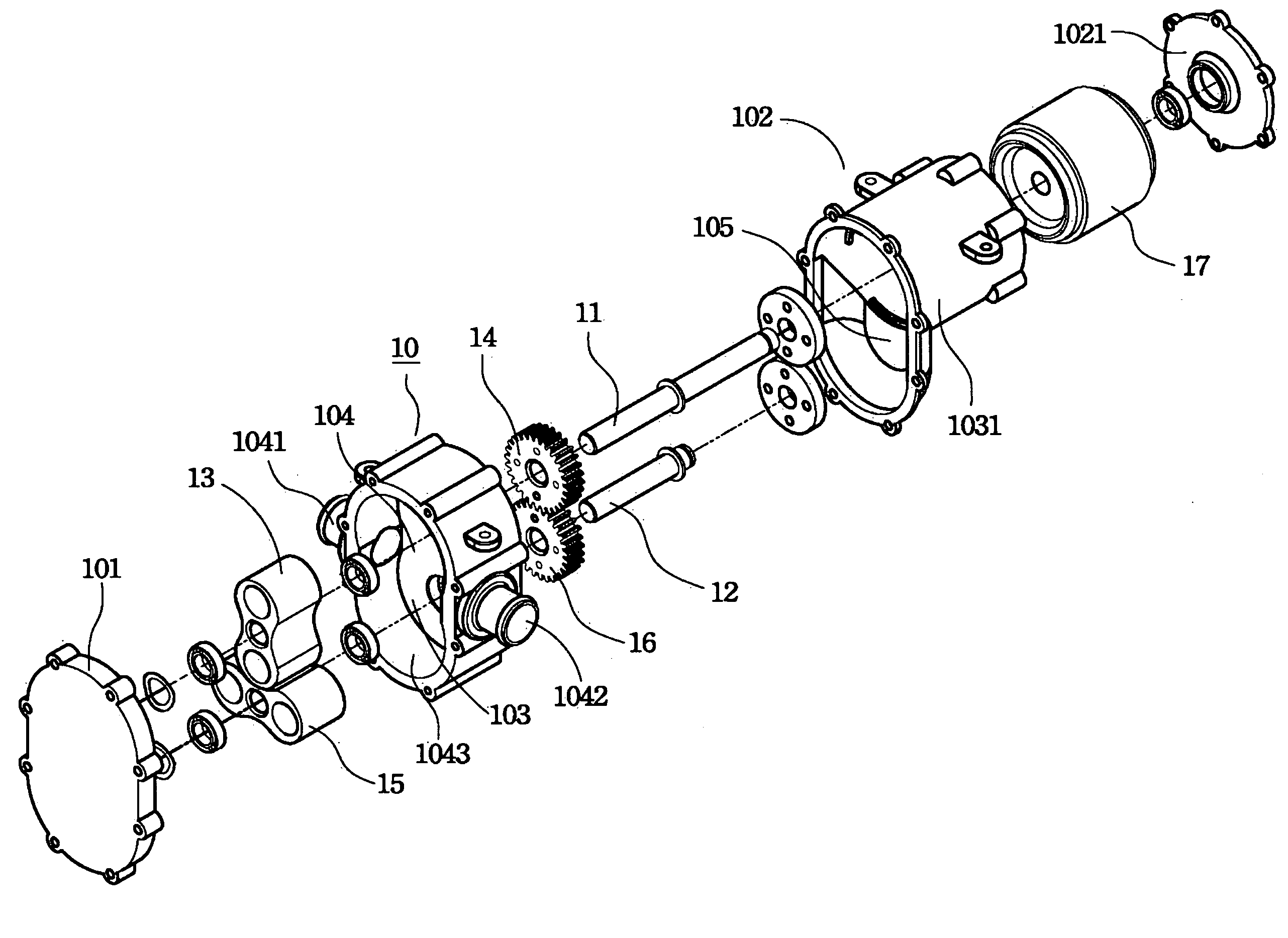

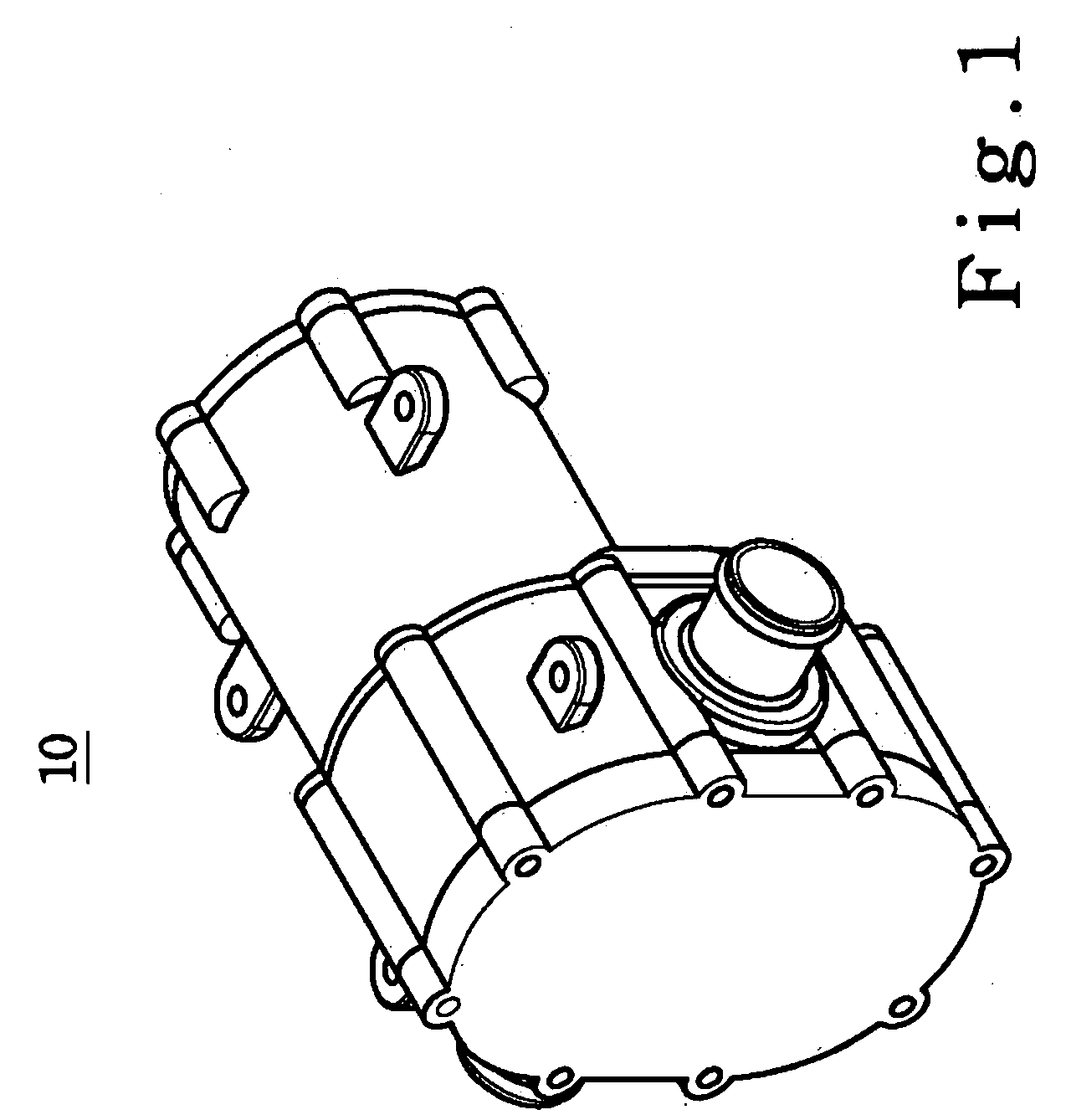

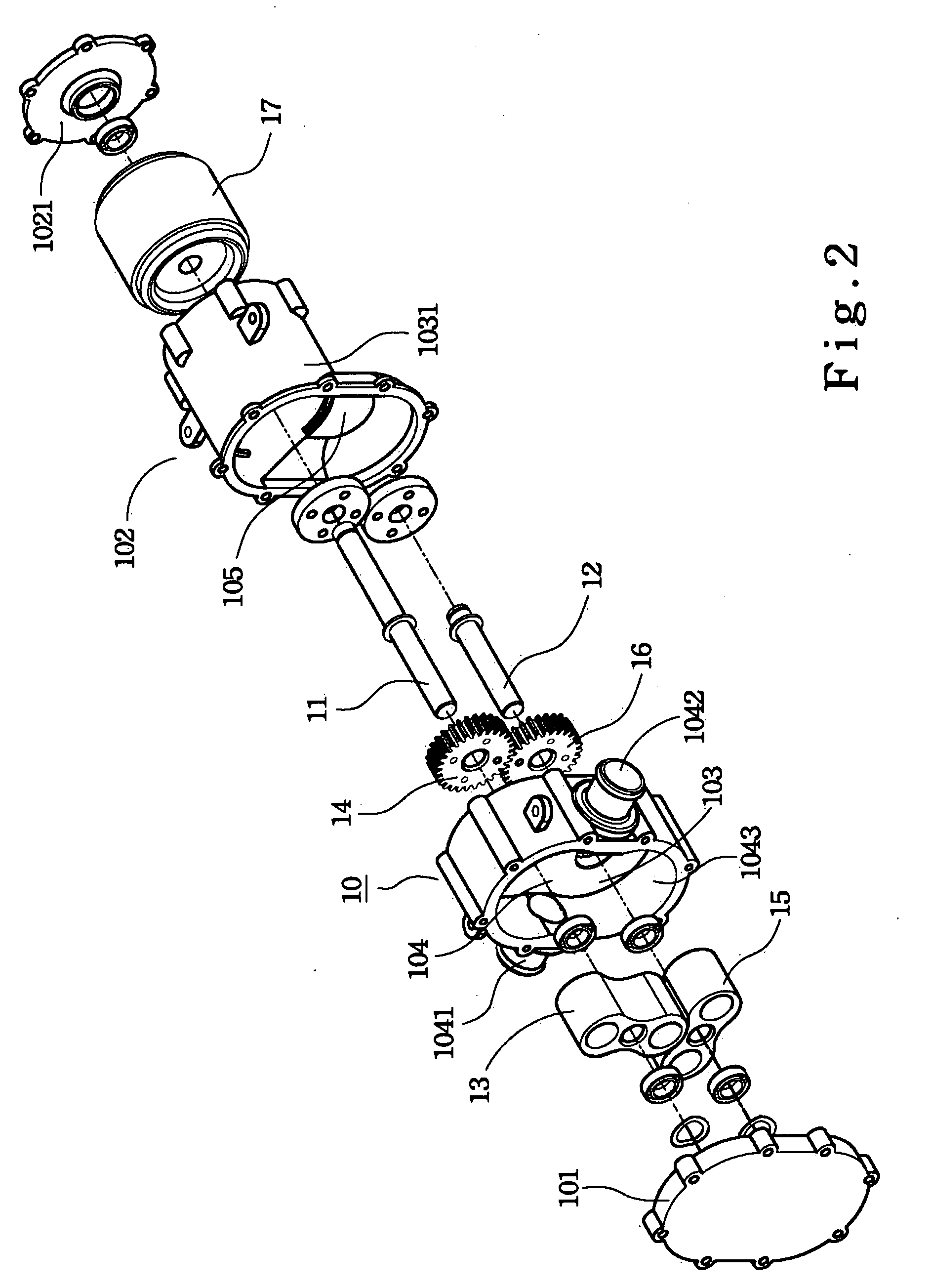

Image

Examples

first embodiment

[0039]A third preferred embodiment is shown in FIG. 6, which is a sectional view of a motor direct drive compressor having identical characteristics as the aforesaid However, a compressor requires higher air impermeability than that of an air pump in order to provide compressed air of higher pressure. Therefore, seals 20 such as O-shaped rings are disposed at where the first shaft 11 and the second shaft 12 are fittingly disposed through the central partition 103 in this embodiment, and thinly-formed airtight rings 1011 may also be disposed at where the left cover 101 and the central partition 103 are joined if required. As a result, a power outputted from a motor may directly drive the first impeller and the second impeller in the compression chamber without going through an additional coupling, and allow the compressor to output compressed air from the air outlet.

The Fourth Preferred Embodiment

third embodiment

[0040]A fourth preferred embodiment is shown in FIG. 7, which is a sectional view of a motor direct drive compressor having identical characteristics as the aforesaid However, a compressor requires higher air impermeability than that of an air pump in order to provide compressed air of higher pressure. Therefore, seals 20 such as O-shaped rings are disposed at where the first shaft 11 and the second shaft 12 are fittingly disposed through the central partition 103 in this embodiment, and thinly-formed airtight rings 1021 may also be disposed at where the right cover 102 and the central partition 103 are joined if required. As a result, a power outputted from a motor may directly drive the first impeller and the second impeller in the compression chamber without going through an additional coupling, and allow the compressor to output compressed air from the air outlet.

The Fifth Preferred Embodiment

[0041]The invention further proposes a fifth preferred embodiment, which is a motor di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com