Sport fisherman's ice chest with integrated cutting board

a technology for ice chest coolers and fisherman's ice chests, which is applied in the field can solve the problems of cutting on fingers and hands, dangerous to use cutting surfaces, and lack of top/cover lids of ice chest coolers today, and achieves the effect of saving valuable ice and space, increasing the available “walking space” and effectively doubling or tripling the amount of coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Description of the Preferred Embodiment

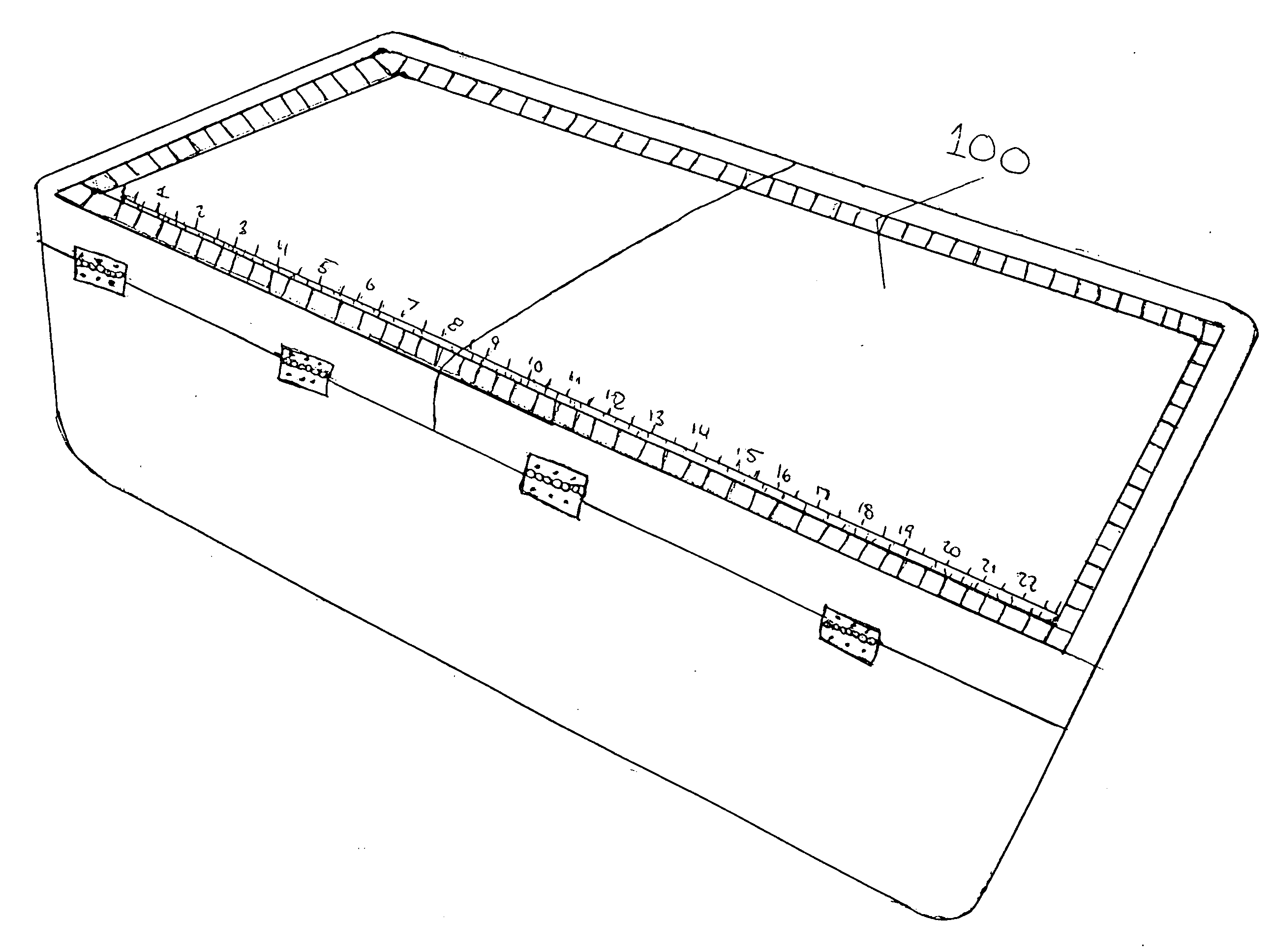

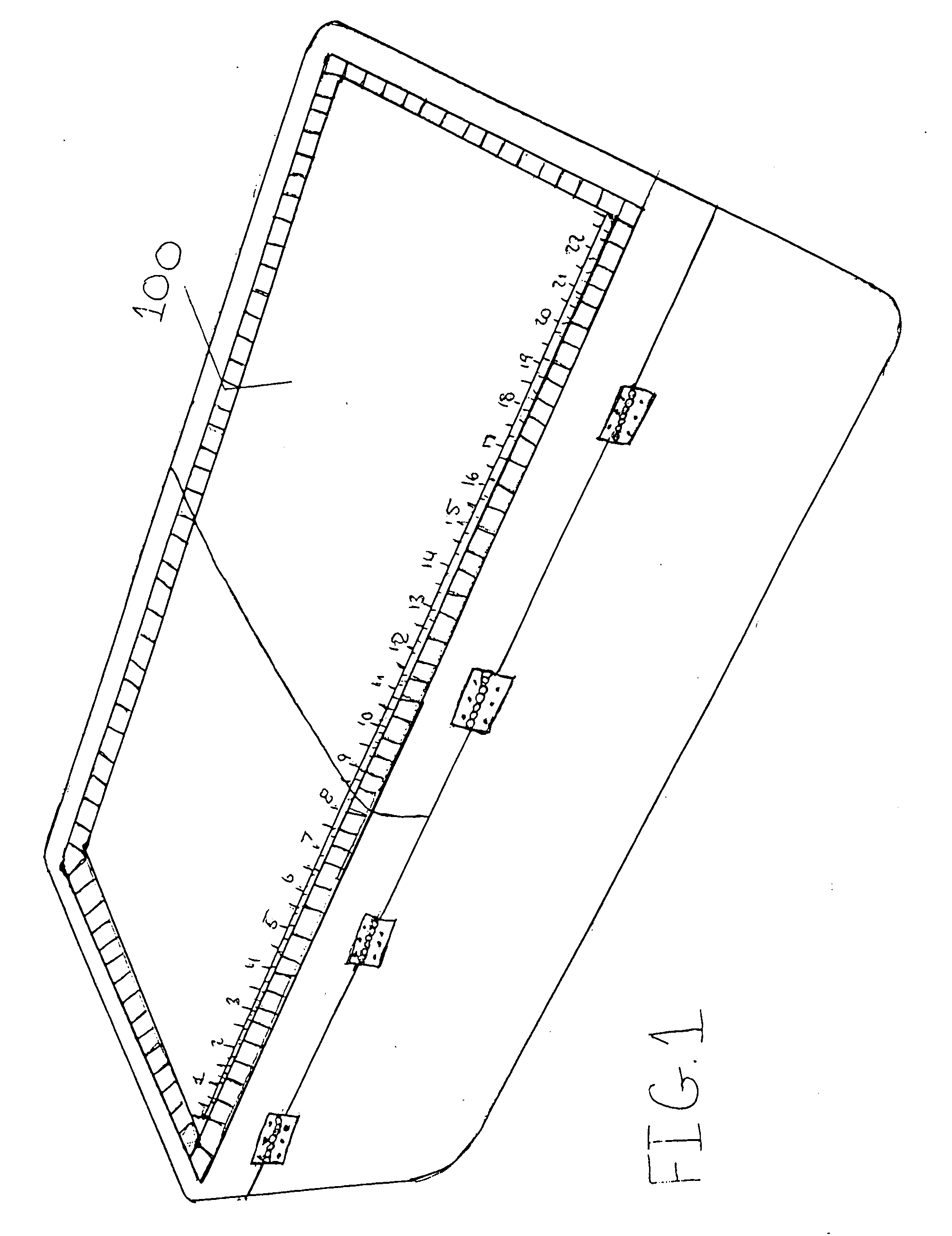

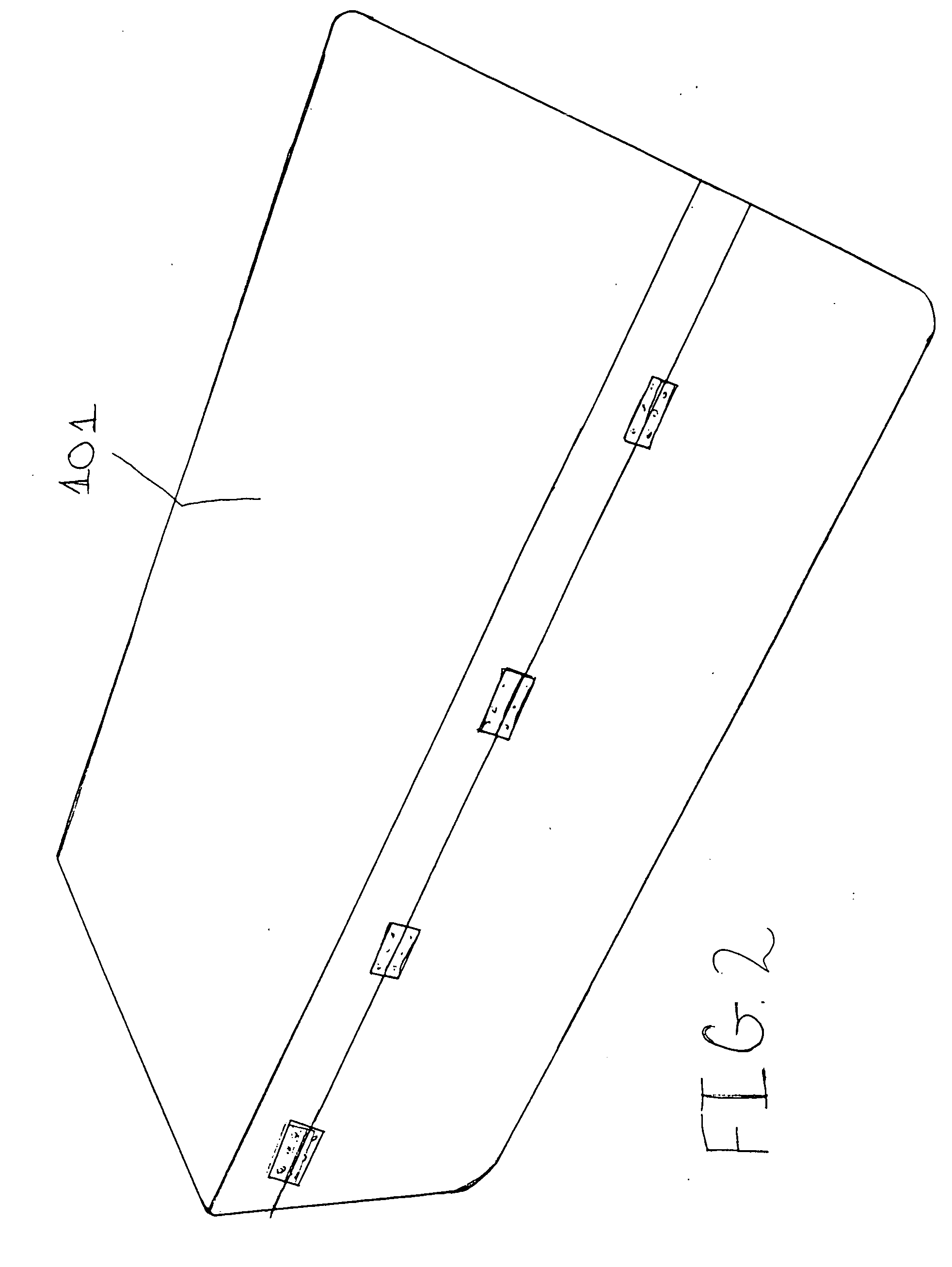

[0010]The embodiment of the cover / top cooler design need only be made perfectly flat and smooth with rounded corners—i.e., without any “lip” to catch the blood which might dry and make clean up more of an effort. No other modification to the cooler's lid is warranted in the preferred embodiment. See drawings FIG. 1 vs. FIG. 2.

[0011]Wash the cooler top clean with your wash down pump or throw a bucket of water on the cooler top, and the blood and fish pieces will go out the boat's “scuppers”. Larger pieces can then be picked out of the boat “scuppers” and thrown into the sea for fish and marine life to feed on.

[0012]There are several reasons why being able to “cut” fish at sea is highly desirable; and highly undesirable at the marina cutting station, or at your dock by your house, or dragging a heavy cooler full of whole fish and much ice home for the “cutting”; and all these heretofore latter methods are highly undesirable—even stupid.

[0013]Biti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com