Powder classifying device

a classifying device and powder technology, applied in the direction of gas current separation, solid separation, chemistry apparatus and processes, etc., can solve the problems of inability to achieve satisfactory results in terms of classification accuracy and operability (or particle size controllability), complicated structure of the device, etc., to achieve easy particle size control and maintenance, high degree of accuracy, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0121]A specific example is described below.

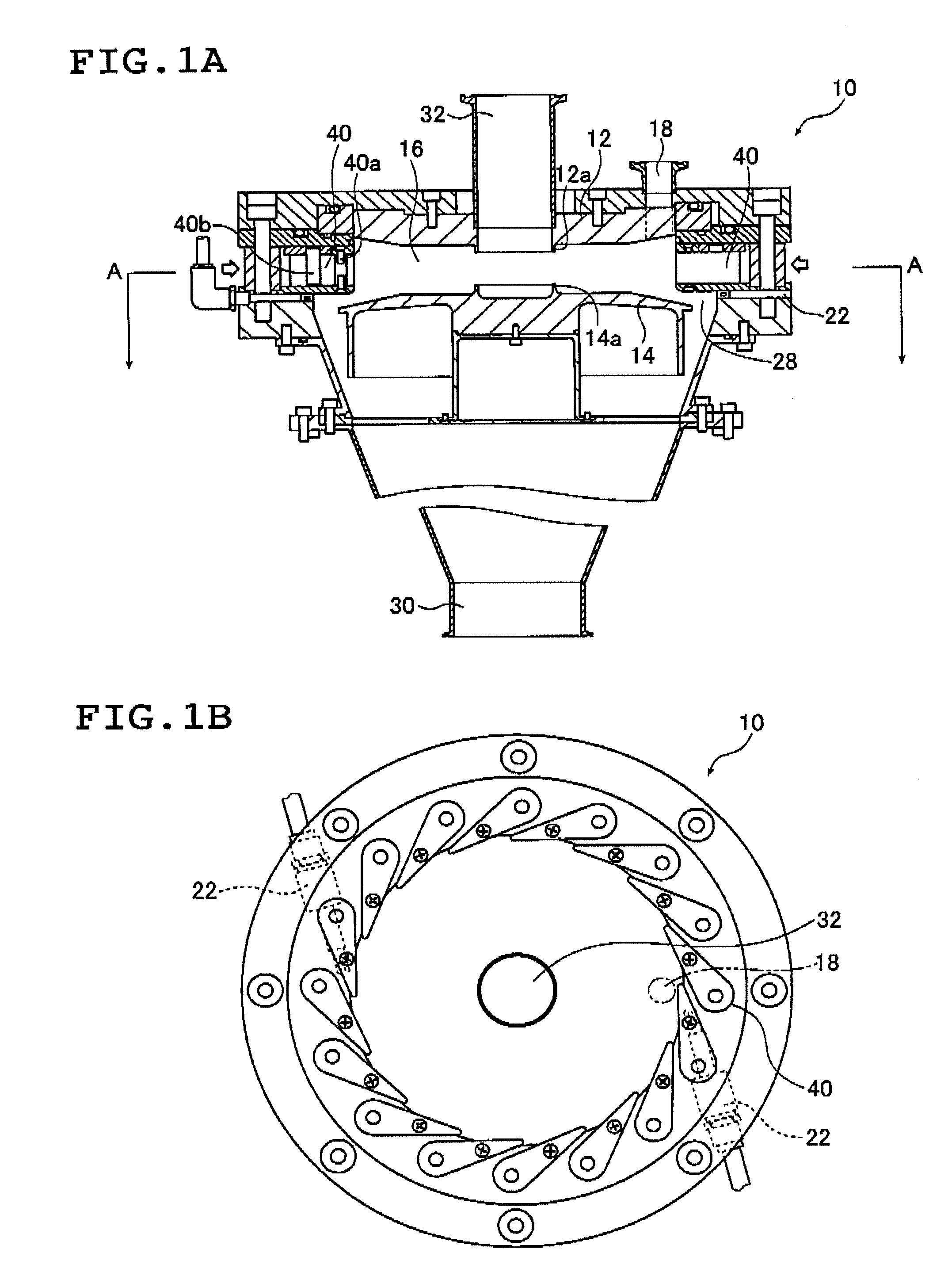

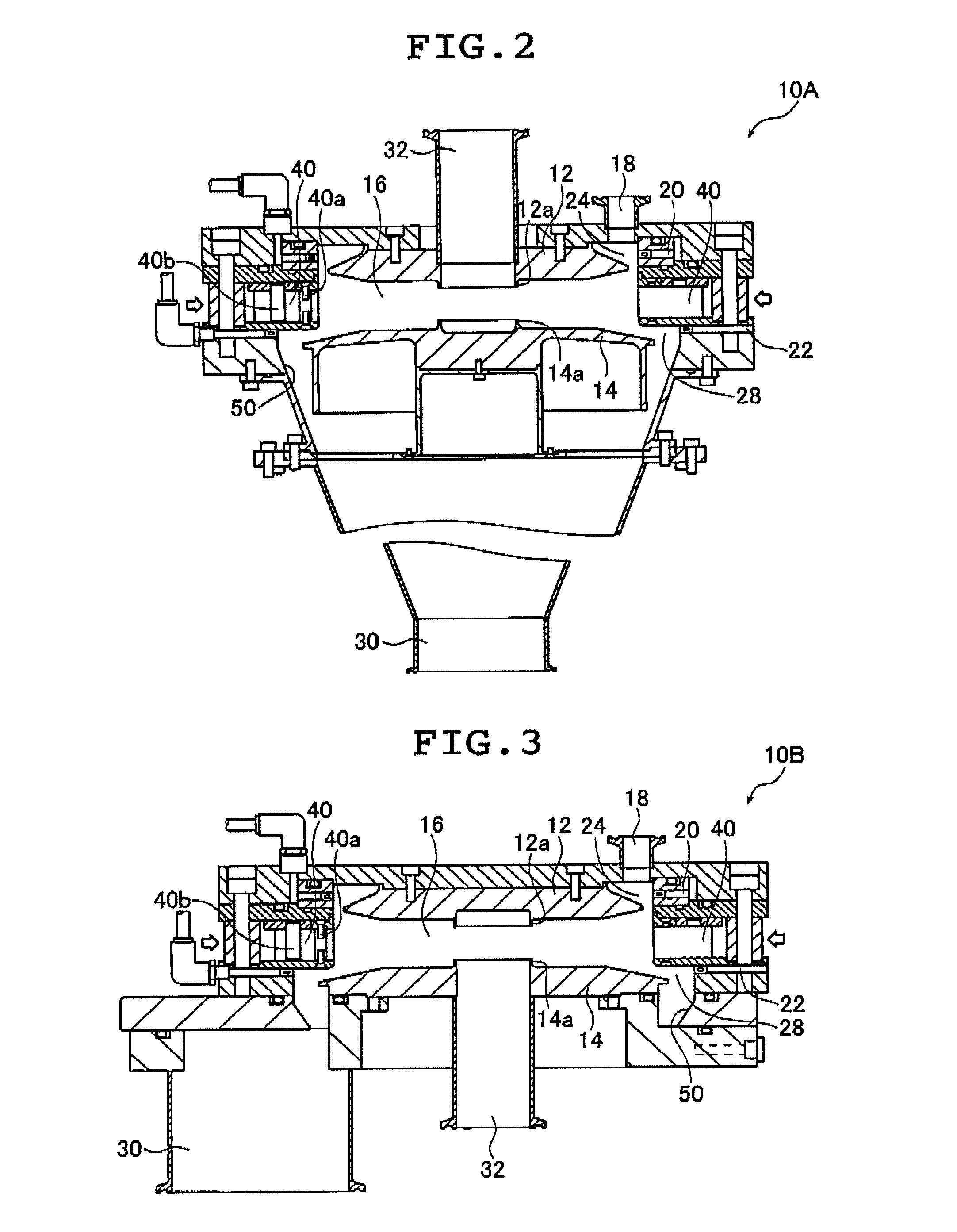

[0122]The powder classifying device 10A having the configuration shown in FIG. 2 was used in Example 1, and a powder classifying device obtained by removing the two types of nozzles including the first and second discharge nozzles 20 and 22 and the ring-like edges 12a and 14a provided on the upper side and the lower side of the centrifugal chamber 16 from the powder classifying device 10A having the configuration shown in FIG. 2 was used as a conventional powder classifying device in Comparative Example 1.

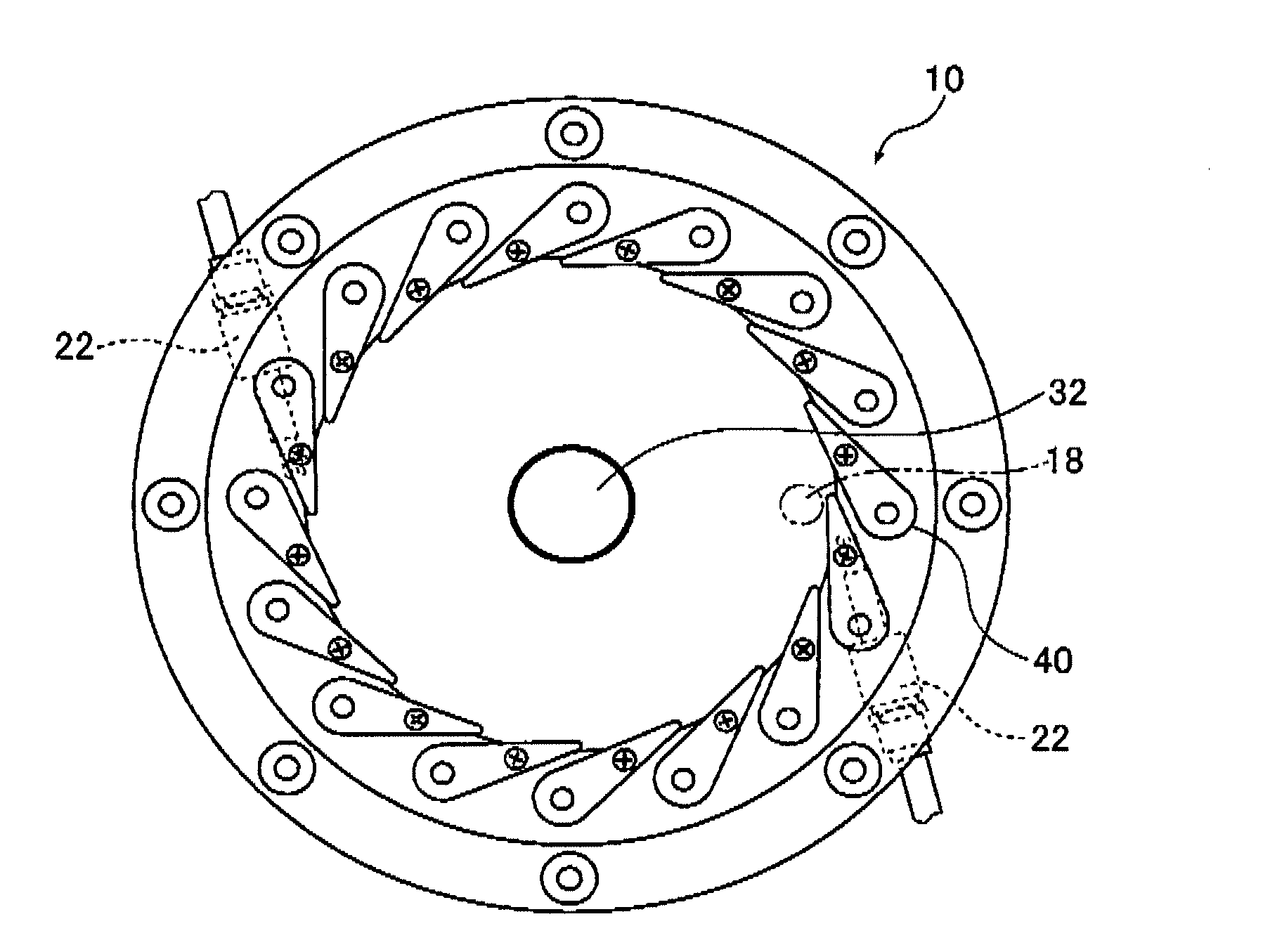

[0123]The inclination angle of the guide vanes 40 from the tangential direction of the outer peripheral wall toward the center of the centrifugal chamber 16 within the powder classifying device was set to 10 degrees in both Example 1 and Comparative Example 1.

[0124]In Example 1, the pressure of air discharged from the upper and lower discharge nozzles 20 and 22 was set to 0.5 MPa and the flow rate of air discharged per nozzle was set to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inclination angle | aaaaa | aaaaa |

| inclination angle | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com