Variable area turbine vane arrangement

a turbine and variable area technology, applied in the direction of machines/engines, reaction engines, liquid fuel engines, etc., can solve the problems of reducing the structural integrity and durability of the nozzle segments, reducing the pressure loss of the turbine, and leaking, etc., to reduce the cost and weight, the effect of reducing the loss of the turbine pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

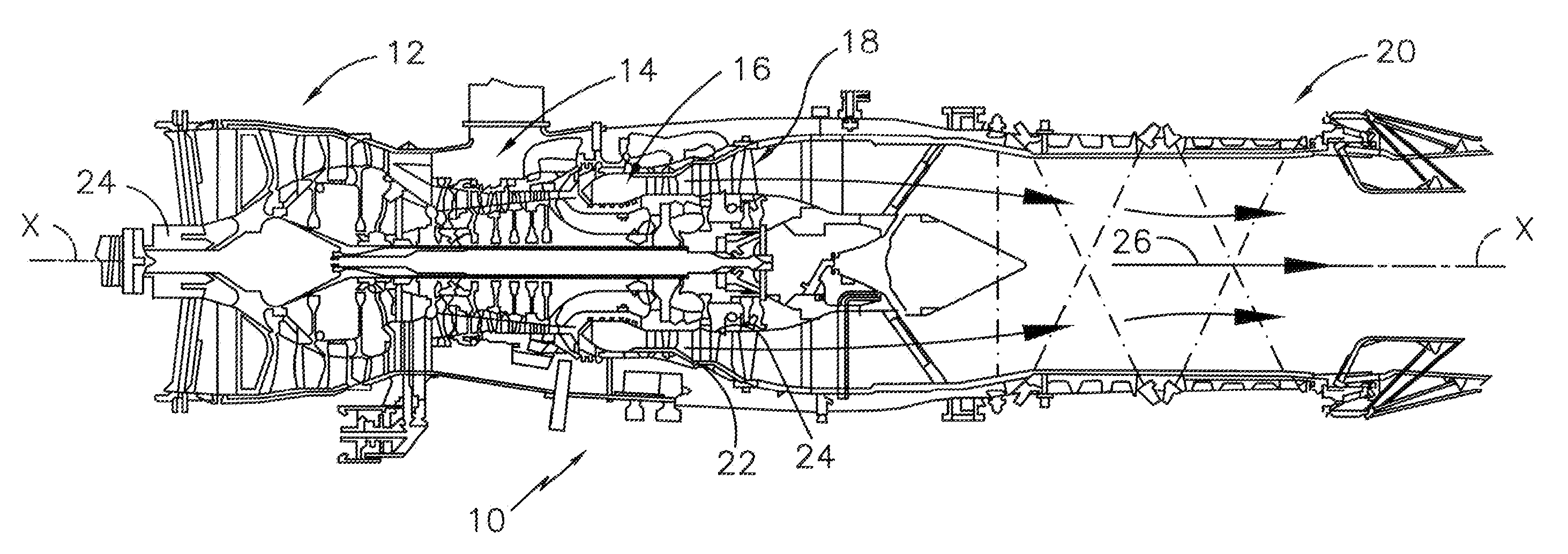

[0013]FIG. 1 schematically illustrates a gas turbine engine 10 which generally includes a fan section 12, a compressor section 14, a combustor section 16, a turbine section 18, and a nozzle section 20 along a longitudinal axis X. The gas turbine engine 10 of the disclosed embodiment is a relatively low bypass gas turbine engine. Although the disclosed embodiment illustrates a 3-stage fan, a 6-stage compressor, an annular combustor, a single stage high-pressure turbine, and a 2-stage low pressure turbine, various other gas turbine engines will benefit from the present invention.

[0014]The engine 10 is configured to provide a variable area turbine nozzle to selectively control the flow of the combustion gas 12 from the combustor section 16 through the turbine section 18. The engine 10 is also referred to as including a Controlled Area Turbine Nozzle (CATN).

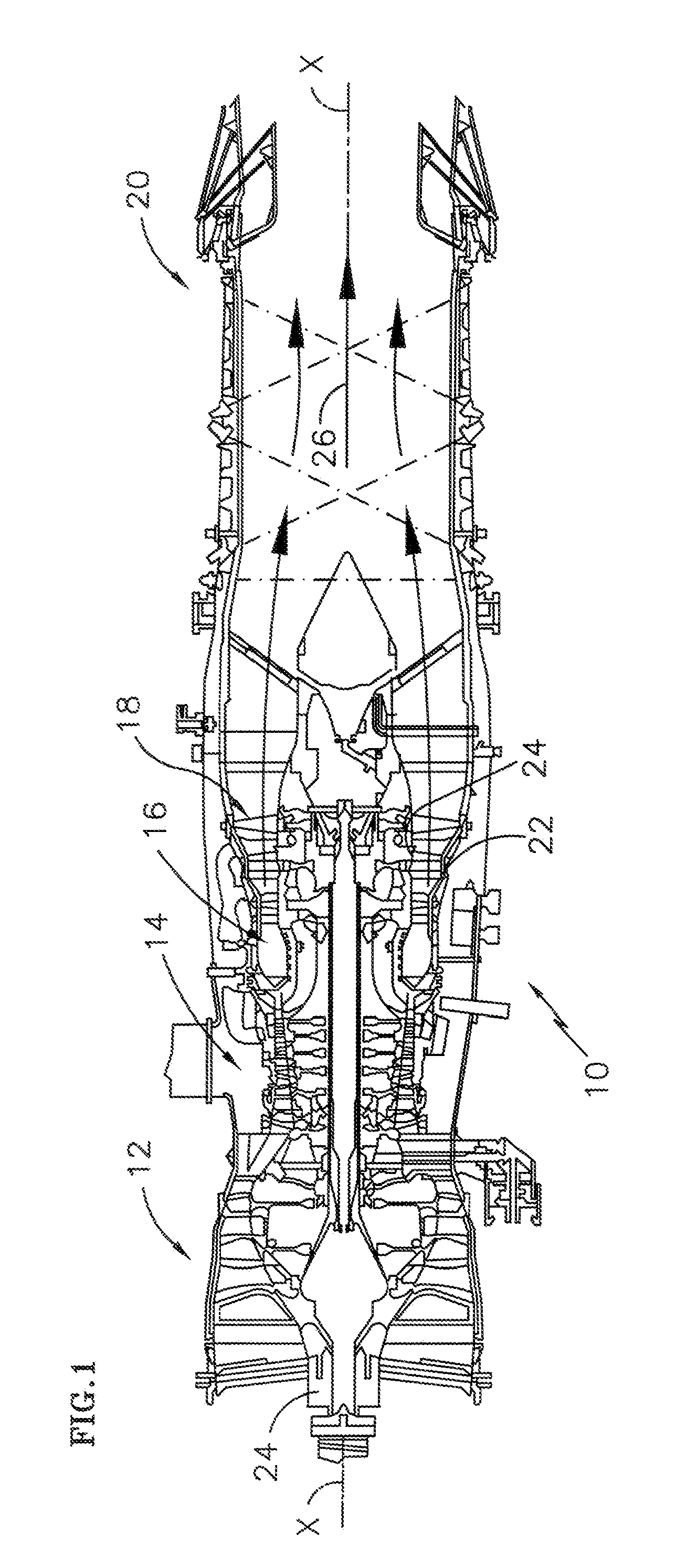

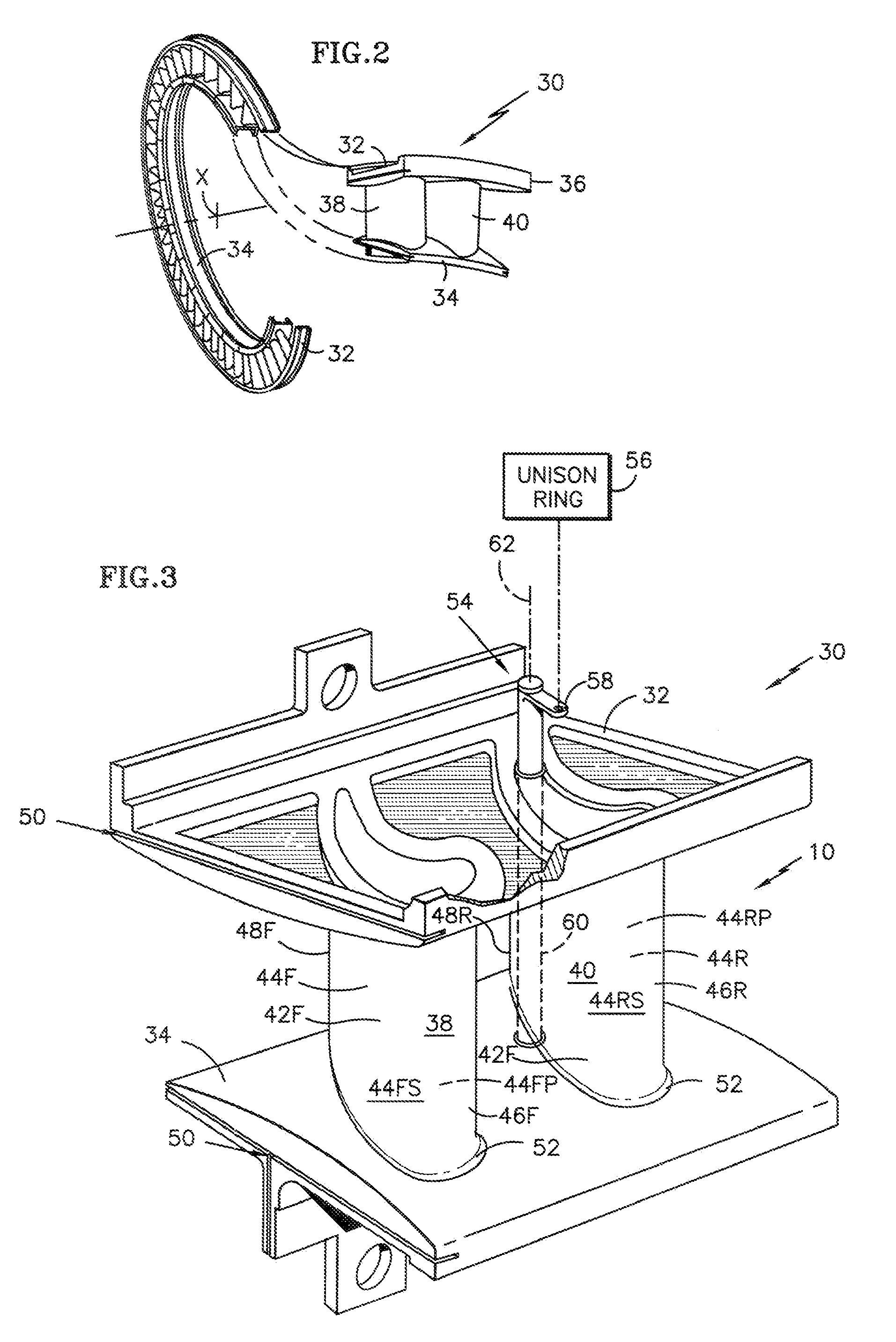

[0015]Referring to FIG. 2, a turbine nozzle segment 30 includes an arcuate outer vane platform segment 32 and an arcuate inner vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com