Submerged type hollow fiber membrane module

A manufacturing method and fiber membrane technology, applied in the field of submerged hollow fiber membrane modules and their packaging process, can solve the problems of low sealing strength and low sealing strength, and achieve the effects of preventing cost increase, preventing separation, and minimizing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

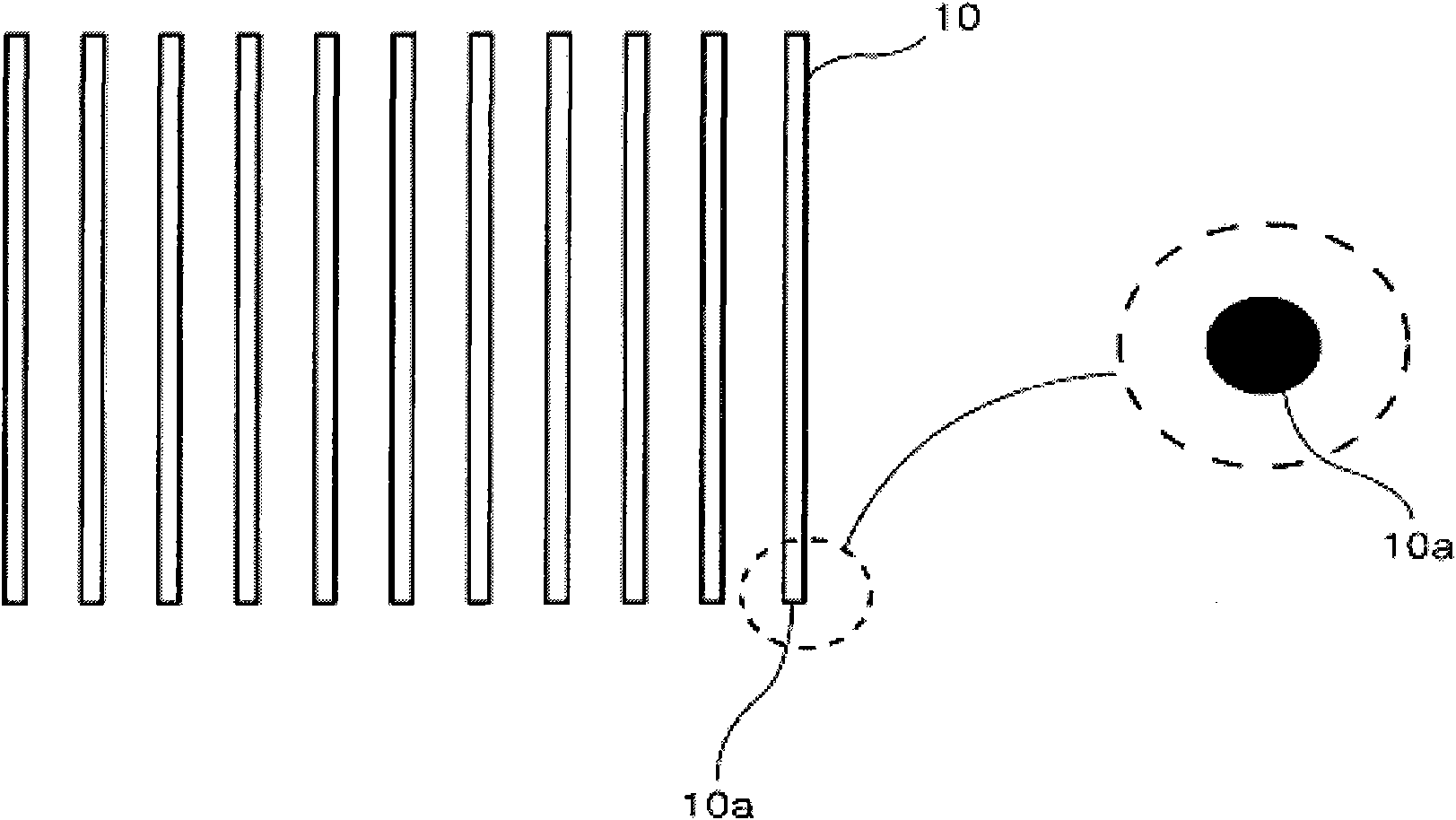

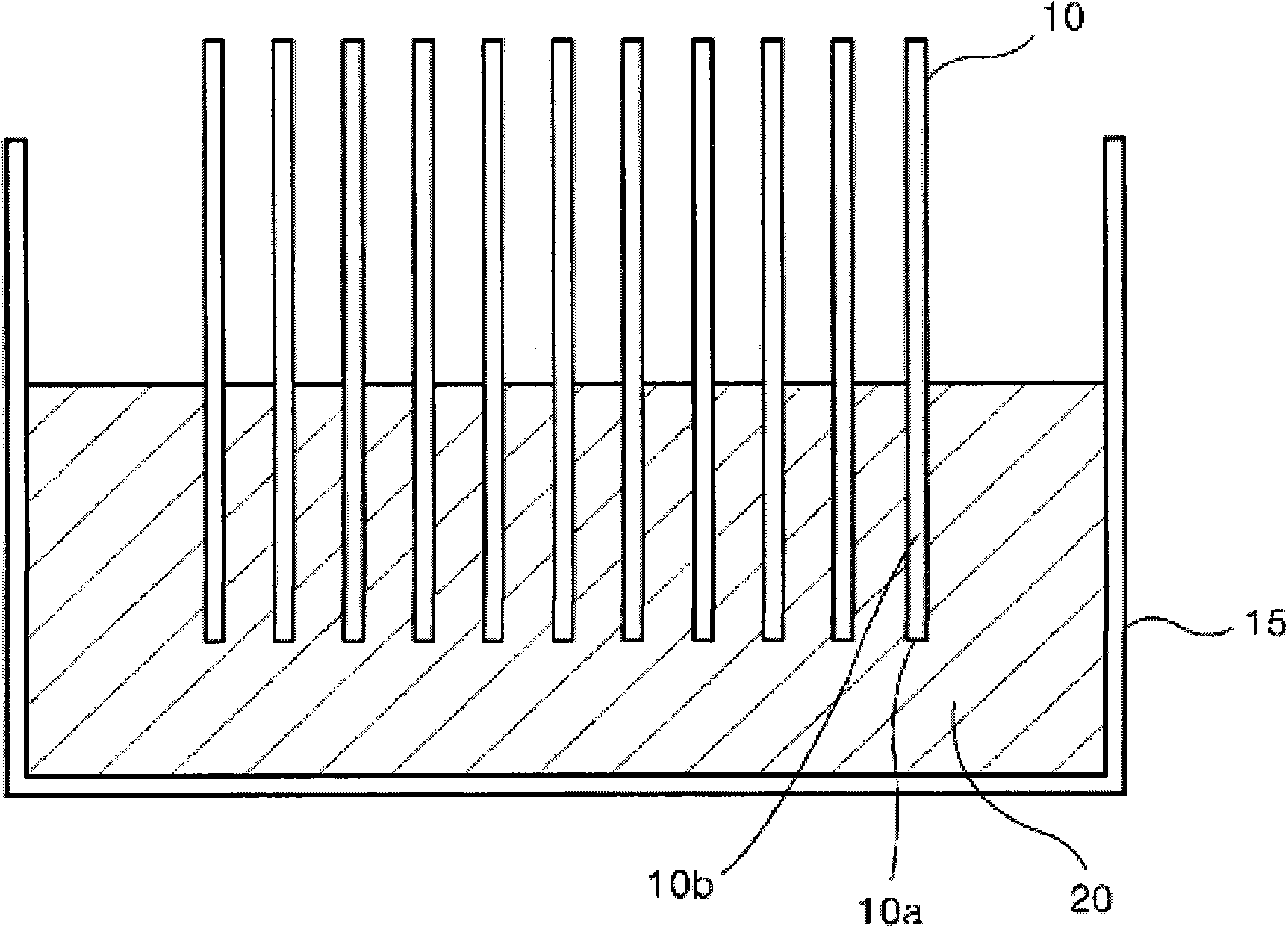

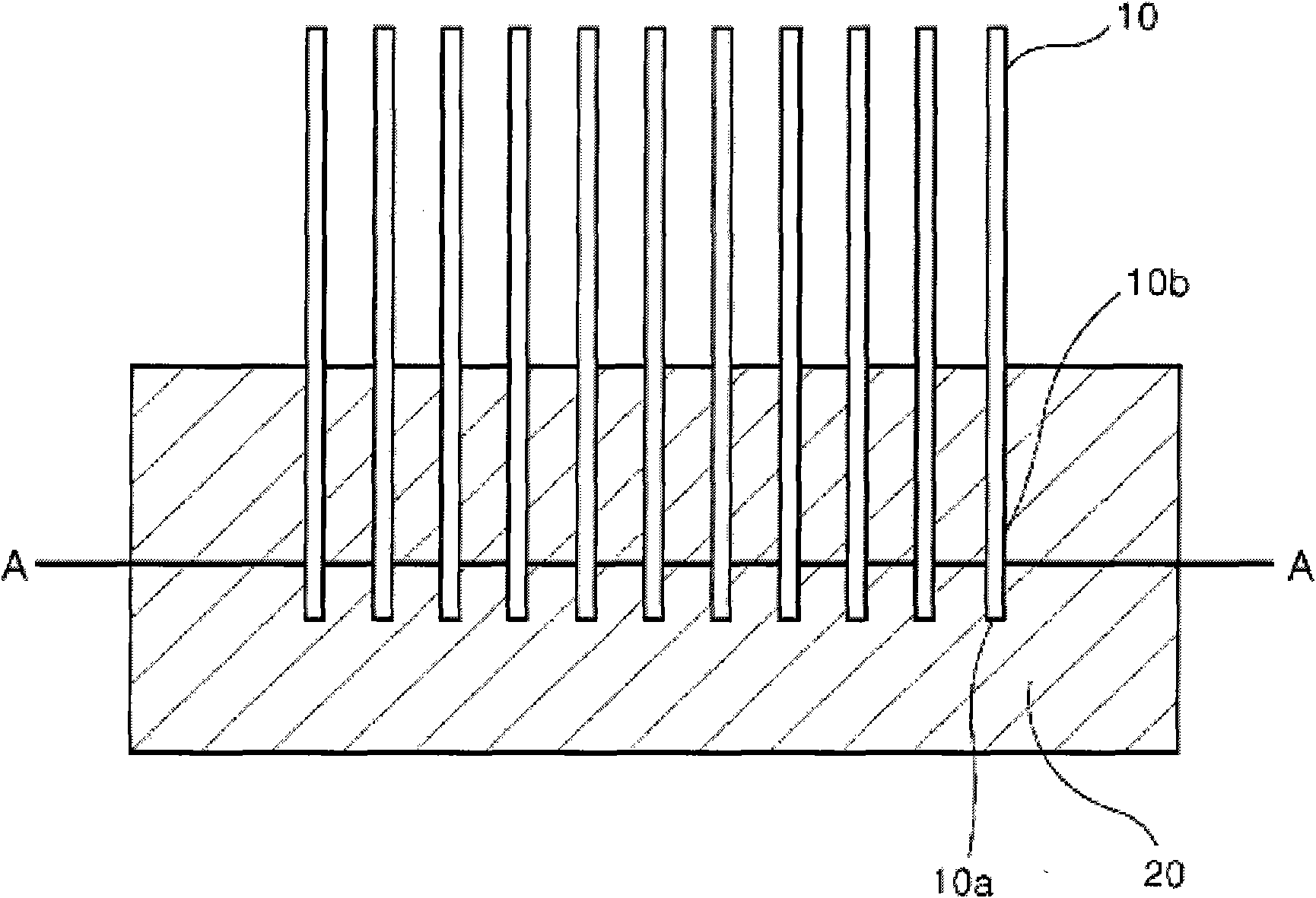

[0046] Figure 1 to Figure 6 is a sectional view schematically showing a method of manufacturing a submerged hollow fiber membrane module according to a first embodiment of the present invention.

[0047] First, if figure 1 As shown, a plurality of hollow fiber membranes 10 were prepared, wherein one end 10a of each hollow fiber membrane 10 was sealed.

[0048] The hollow fiber membranes 10 can use different kinds of materials and forms generally known to those skilled in the art.

[0049] The process of sealing the one end 10a of each hollow fiber membrane 10 may include: sealing the one end 10a of each hollow fiber membrane 10 by immersing the one end 10a of each hollow fiber membrane 10 in a sealant such as paraffin; One end 10a of each hollow fiber membrane 10 is used to seal one end 10a of each hollow fiber membrane 10. exist figure 2 In the following steps, when the hollow fiber membranes 10 are immersed in the first packaging material 20, one end 10a of each hollow...

no. 2 example

[0064] Figure 7 to Figure 10 is a sectional view schematically showing a method of manufacturing a submerged hollow fiber membrane module according to a second embodiment of the present invention. The method according to the second embodiment of the present invention is the same as the method according to the first embodiment of the present invention except that the third encapsulating material is disposed on the second encapsulating material 40 .

[0065] First, if Figure 7 As shown, a plurality of hollow fiber membranes 10 whose one ends 10c are open are fixed by a first packaging material 20, thereby forming a hollow fiber membrane bundle.

[0066] The bundle of hollow fiber membranes is formed such that one end 10 c of each hollow fiber membrane 10 is flush with the cutting plane 20 c of the first encapsulating material 20 . The process of forming hollow fiber membrane bundles and Figure 1 to Figure 4 The formation process is the same.

[0067] Such as Figure 8 As...

no. 3 example

[0077] Figure 11 to Figure 15 is a sectional view schematically showing a method of manufacturing a submerged hollow fiber membrane module according to a third embodiment of the present invention. The method according to the third embodiment of the present invention is the same as the method according to the first embodiment of the present invention, except that a third encapsulating material 50 is also disposed and semi-cured on the second encapsulating material 40 .

[0078] First, if Figure 11 As shown, a plurality of hollow fiber membranes 10 with one end 10c open are fixed by a first packaging material 20, thereby forming a hollow fiber membrane bundle.

[0079] The bundle of hollow fiber membranes is formed such that one end 10 c of each hollow fiber membrane 10 is flush with the cutting plane 20 c of the first encapsulating material 20 . The process of forming hollow fiber membrane bundles and Figure 1 to Figure 5 The process is the same.

[0080] Then, if Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com