Exhaust gas recirculation line holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

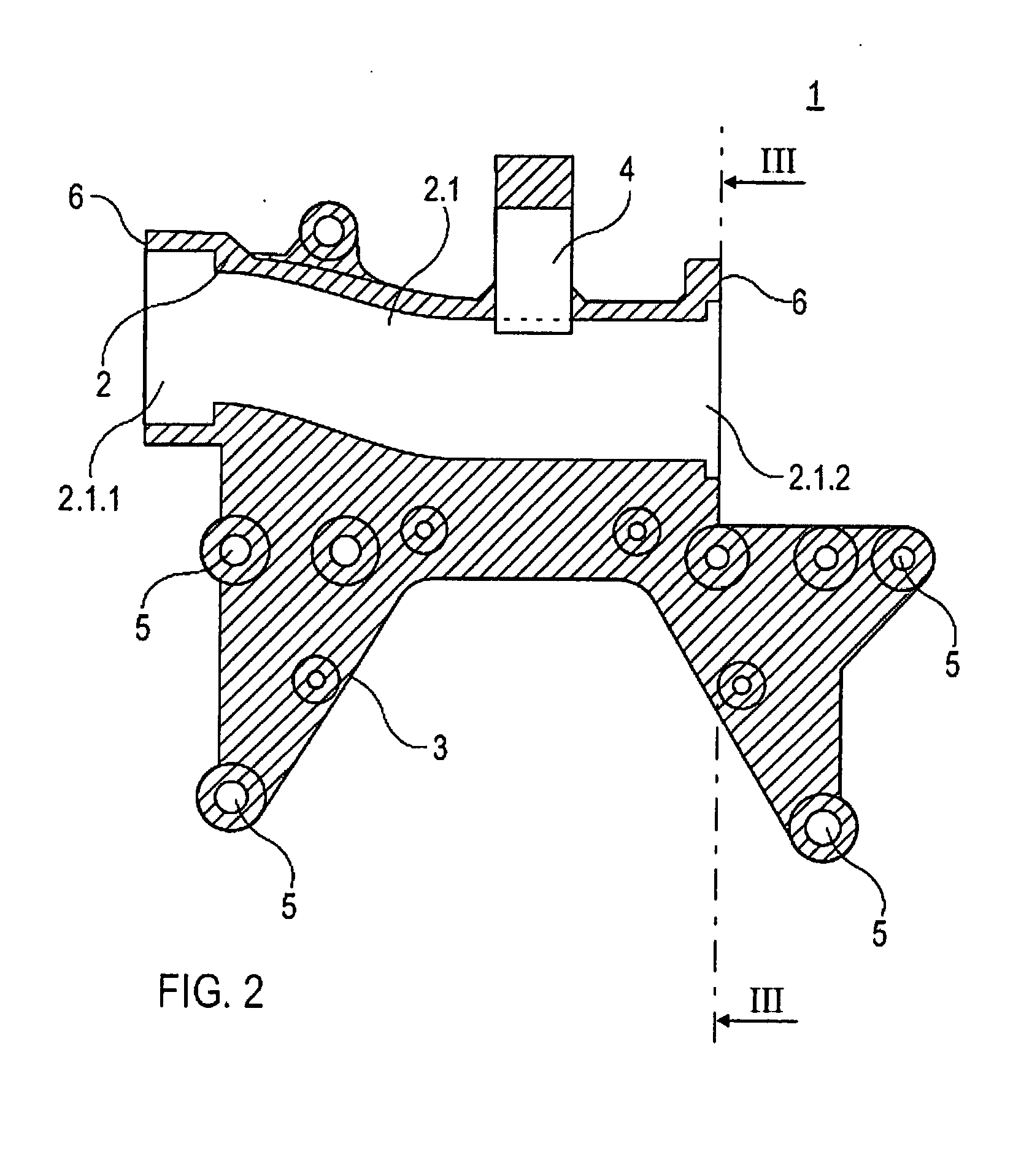

[0014]Parts which correspond to one another are provided with the same designations in all the figures.

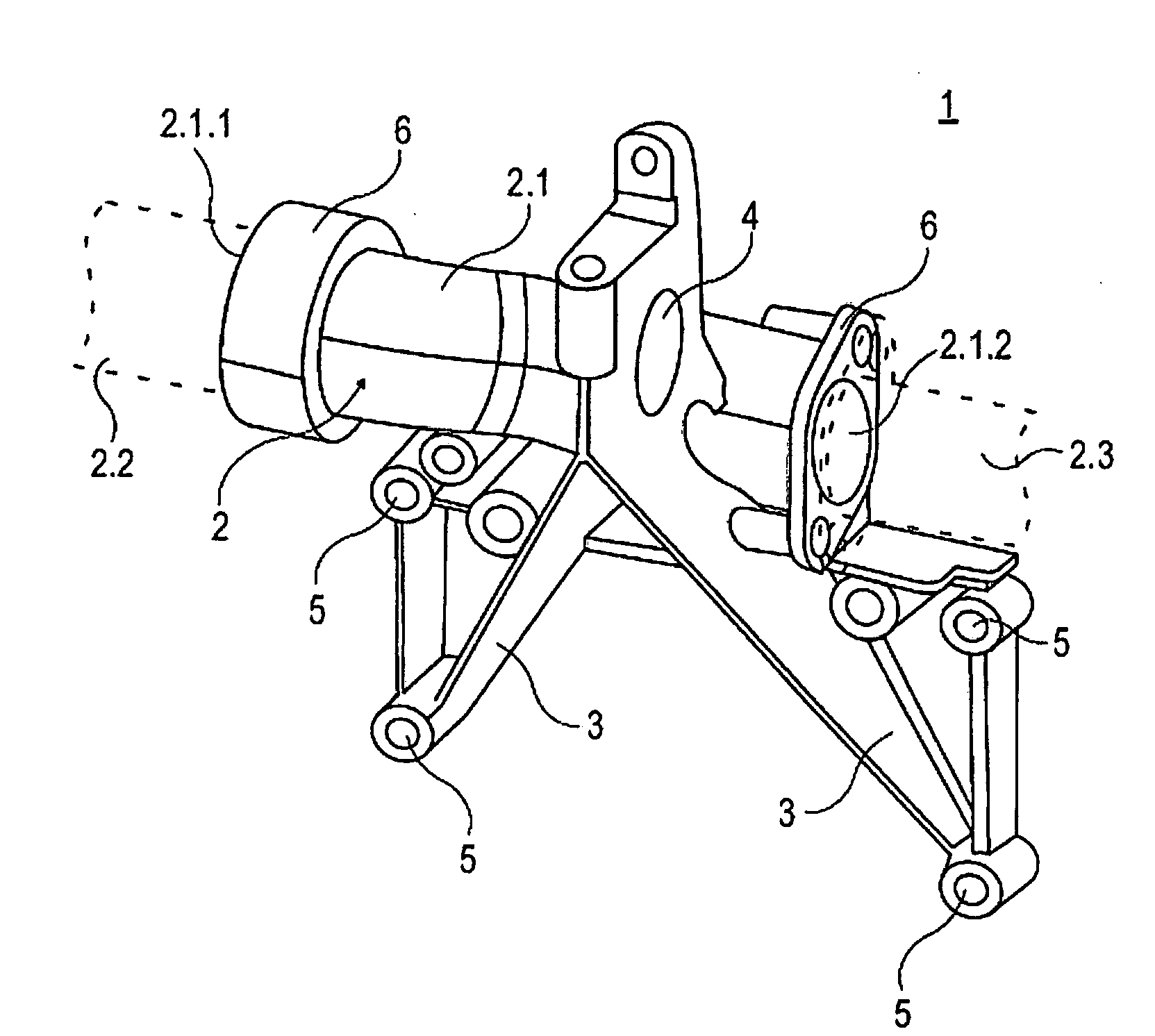

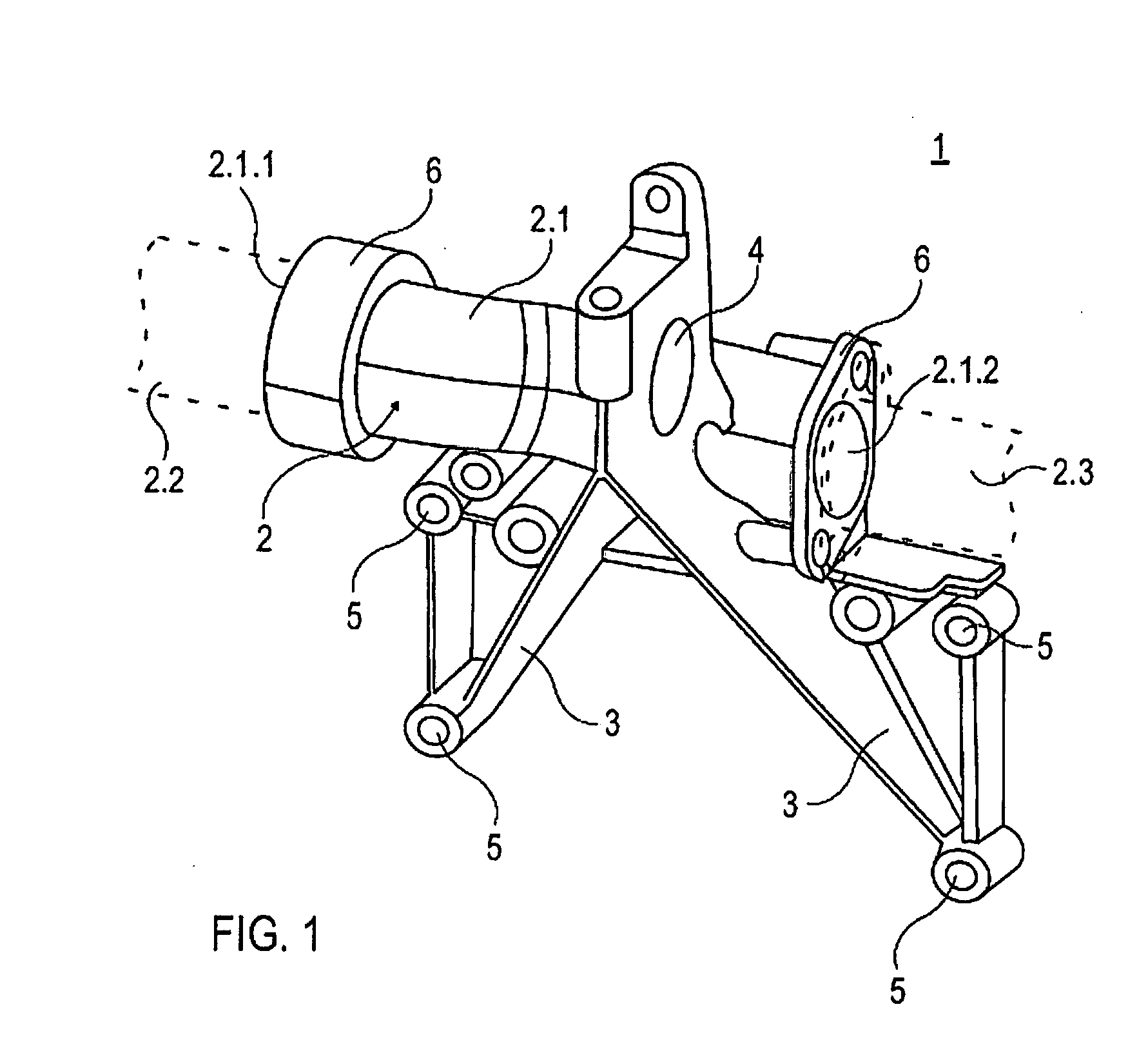

[0015]FIG. 1 shows a holder 1 of a partially integrated exhaust gas recirculation line 2 for an internal combustion engine (not shown).

[0016]The holder 1 is arranged in the form of a connecting component between an engine block (not shown) and a vehicle frame (not shown). In the following text, the holder 1 will be described in detail using the connecting component which is denoted in the following text by the reference numeral 1.

[0017]In order to hold and fasten the holder 1 on the engine block and / or on the vehicle frame, the holder 1 in the exemplary embodiment has two reinforcing elements 3 (also called a support) which are formed as a single piece and are in the form of fastening flanges. The holder 1 is firstly supported on the engine block or vehicle frame via said reinforcing elements 3. Secondly, the holder 1 is fastened via the reinforcing elements 3 by screw- or threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com