Double-effect adsorption refrigeration device

a refrigeration device and double-effect technology, applied in refrigeration machines, climate sustainability, refrigeration safety arrangements, etc., can solve the problems of adsorption cycle technology, heat source temperature needed in refrigeration devices, low coefficient of performance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The present invention proposes a double-effect adsorption refrigerating device having a high Coefficient of Performance (COP) close to 1 while a COP of the conventional device is around 0.7.

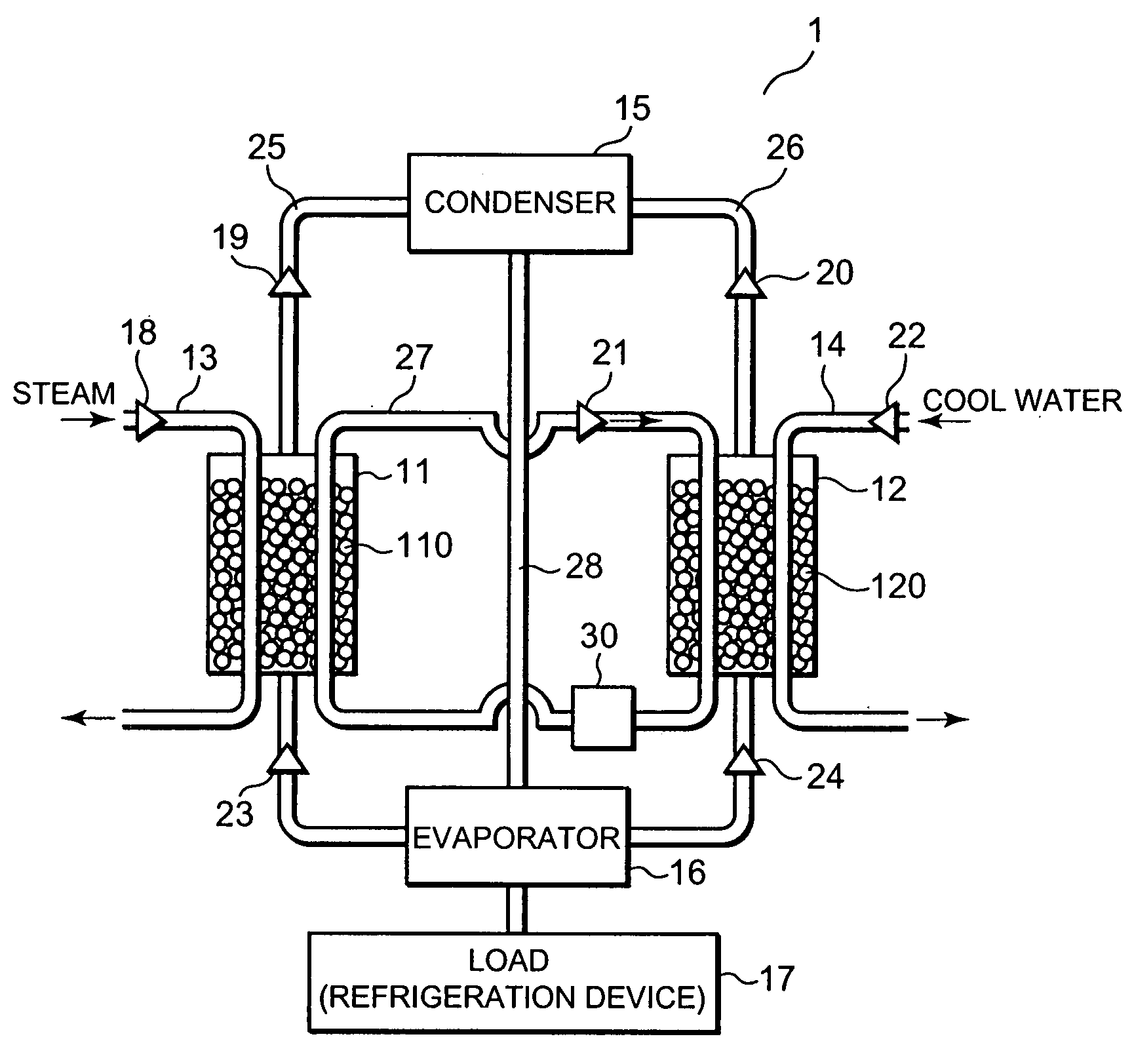

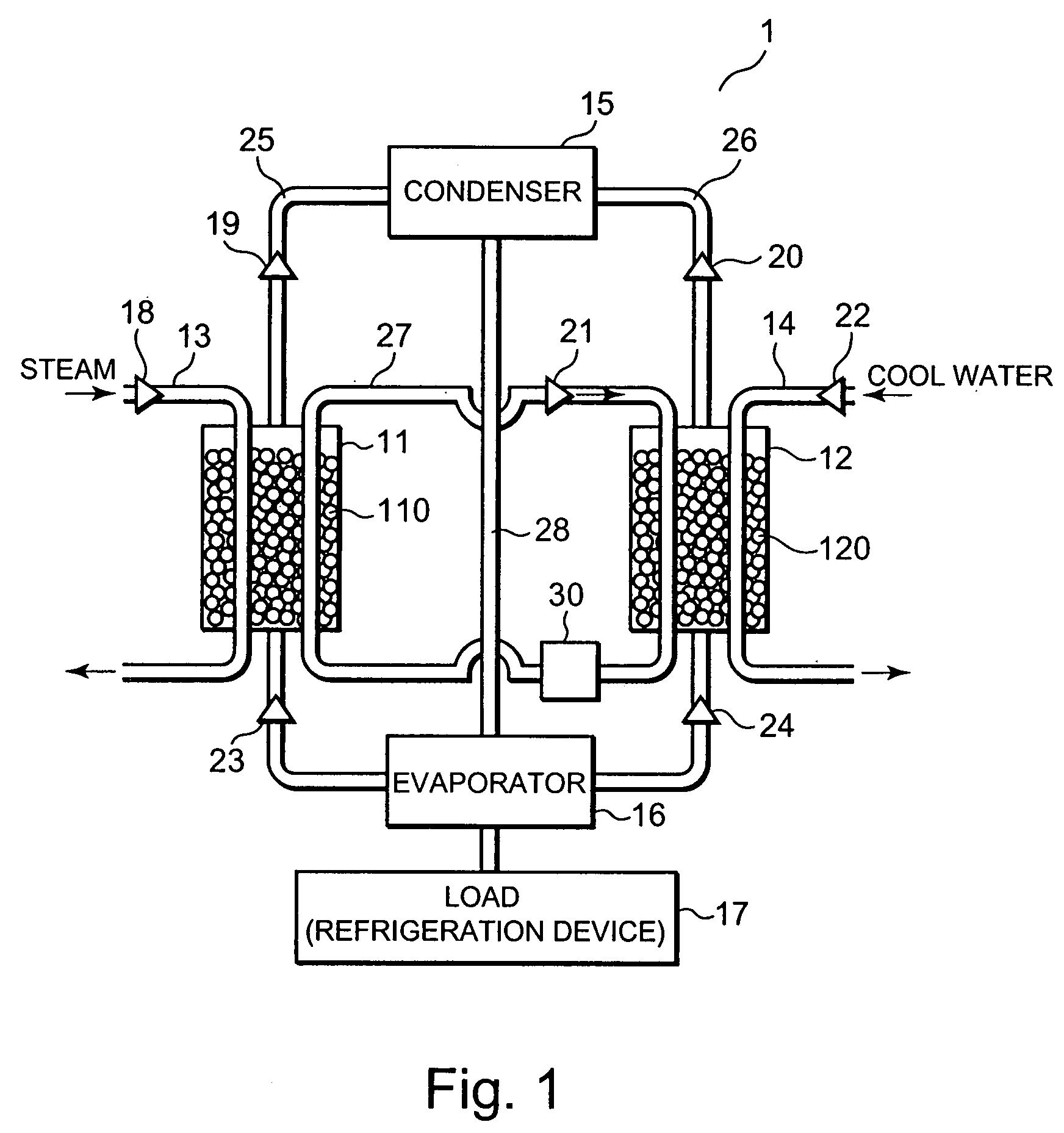

[0019]FIG. 1 shows an example of double-effect adsorption refrigerating device 1 of the present invention in a simple manner but a person skilled in this art could easily understand an actual refrigerating device from the description of the present invention.

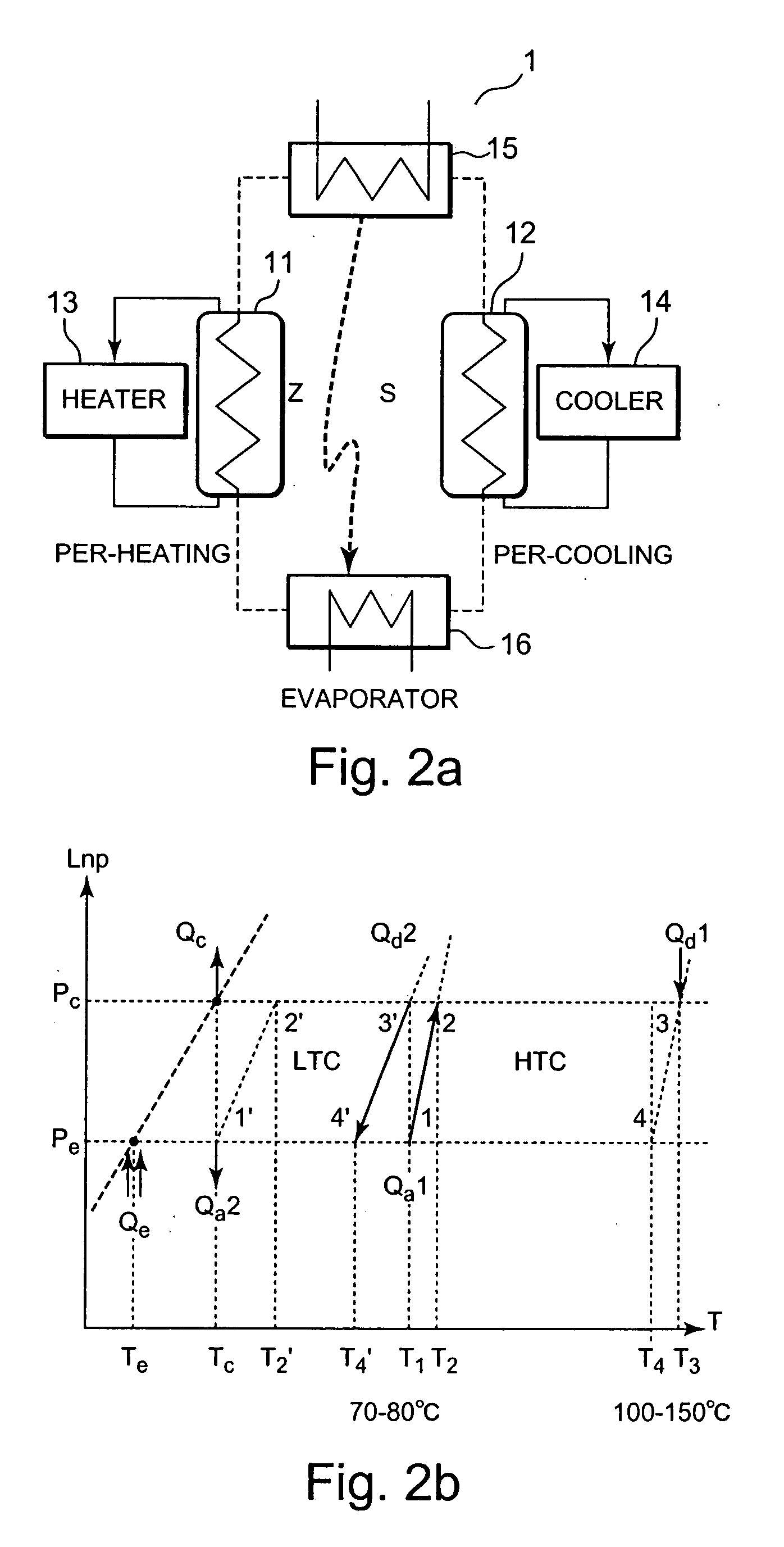

[0020]Referring to FIG. 1, the refrigerating device of the present invention includes a first and second bed 11 and 12 consisting of adsorbent materials of zeolite 110 and silica gel 120 respectively. First bed 11 is designed and used in a high temperature adsorption cycle (HTC), while the second bed 12 is designed and used in a low temperature adsorption cycle (LTC).

[0021]In the double-effect cycle, the high temperature adsorption cycle (HTC) is used as the driving heat for the low temperature adsorption cycle (LTC).

[0022]Back to the F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com