Applications of degradable polymers for delayed mechanical changes in wells

a technology of degradable polymers and mechanical changes, applied in the direction of fluid removal, borehole/well accessories, construction, etc., can solve the problems of no longer effective, no longer having mechanical strength, and directional or horizontal problems,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

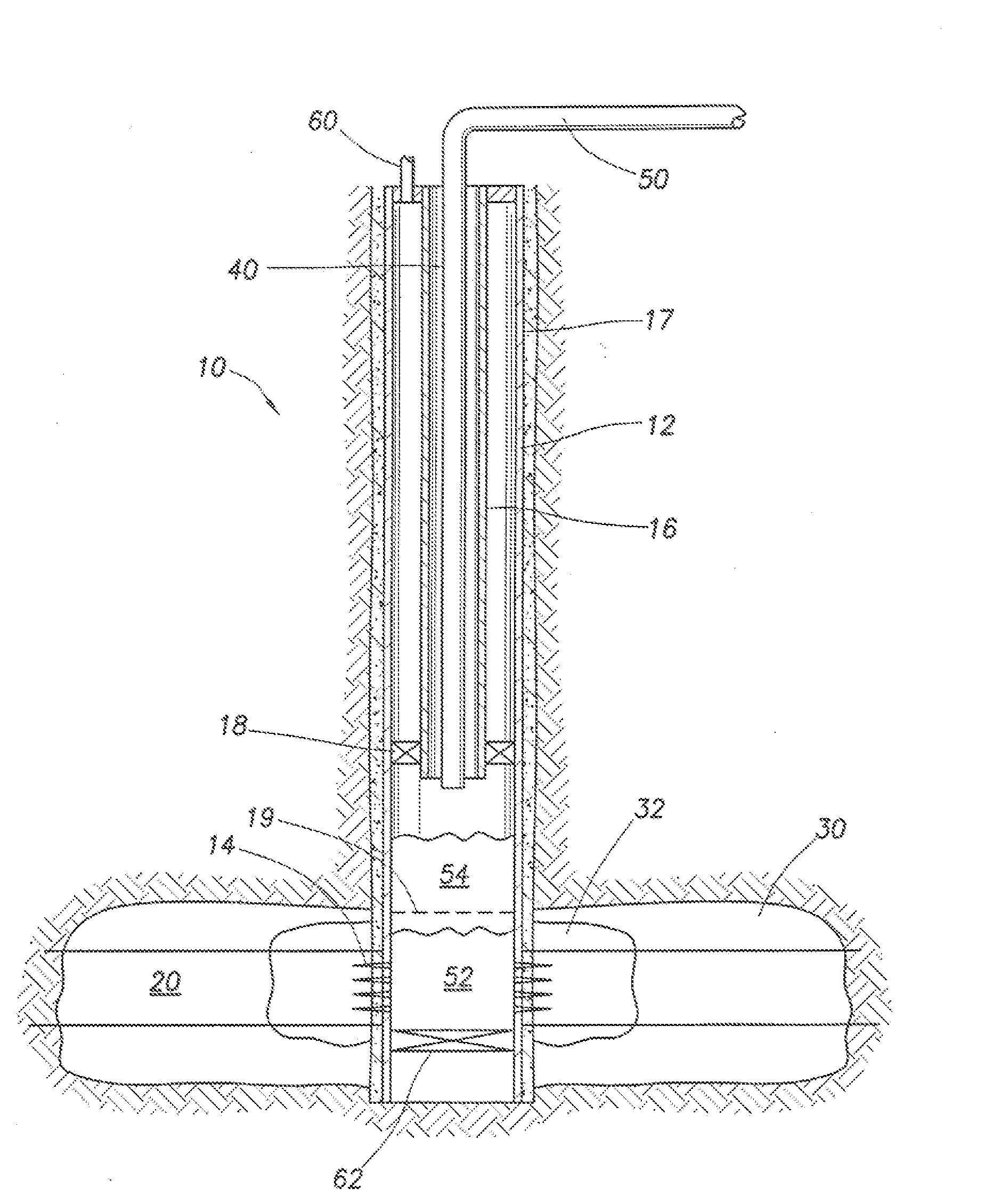

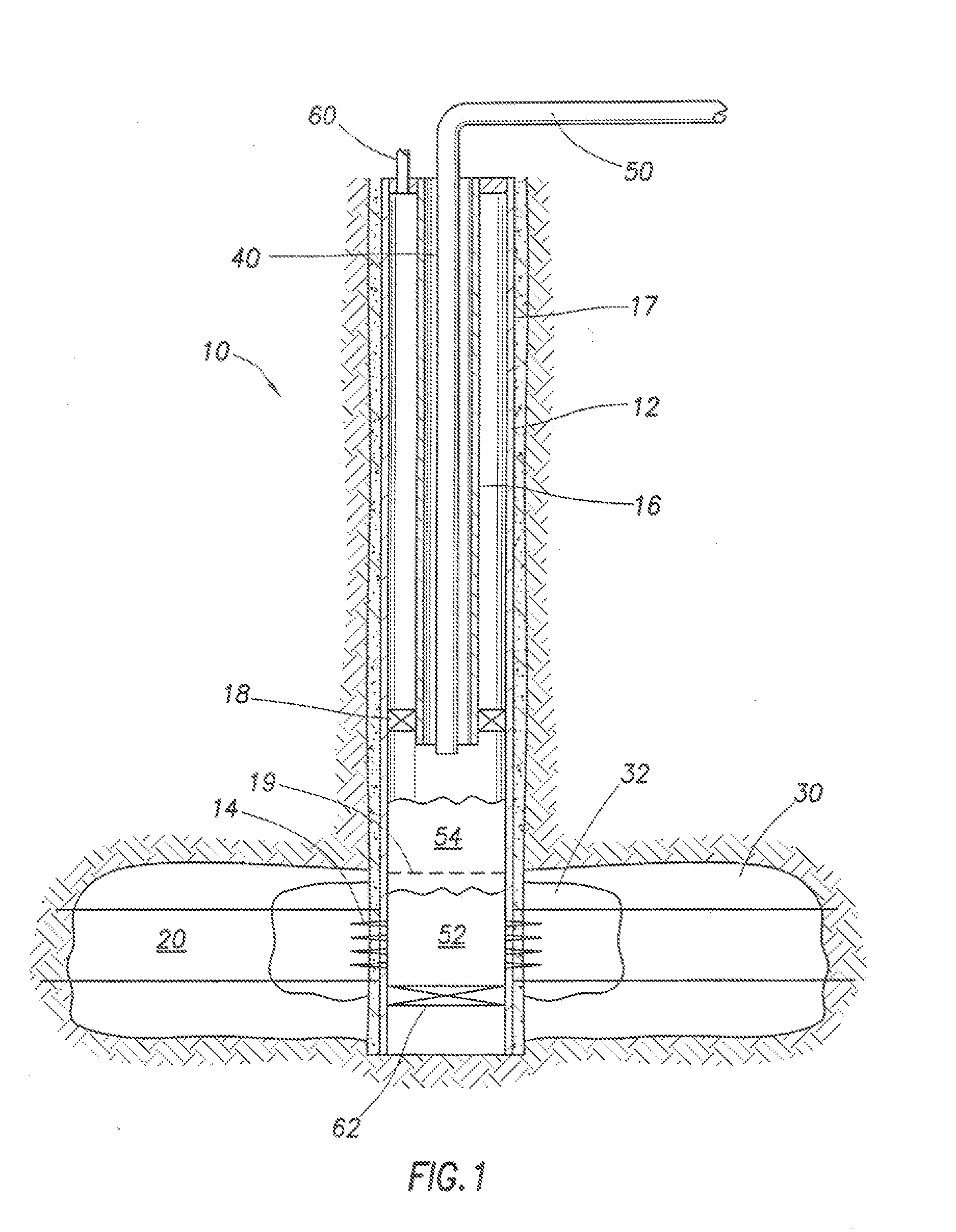

[0016]Referring to FIG. 1, wellbore 10 penetrates formation 20 where fluid is to be produced or injected. Wellbore 10 has casing 12 extending through formation 20, casing 12 being cemented in place by cement sheath 17. Perforations 14 have been formed through the wall of casing 12 and cement sheath 17 into formation 20. Perforations 14 may extend over the entire thickness of formation 20 or may extend only over a selected interval of formation 20 less than the total thickness surrounding wellbore 10. In some wells, hydraulic fracture 30 may have been formed around wellbore 10 by a previous treatment employing conventional fracturing fluid and proppant, using techniques well-known in industry. Alternatively, fracture 30 may not be present. Tubing 16 may have been suspended inside casing 12 and packer 18 may have been set near the bottom of tubing 16 to seal the annulus between tubing 16 and casing 12. Packer 18 may not be present in some wells, tubing 16 may not be present in some we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com