High-performance environmentally friendly building panel and related manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

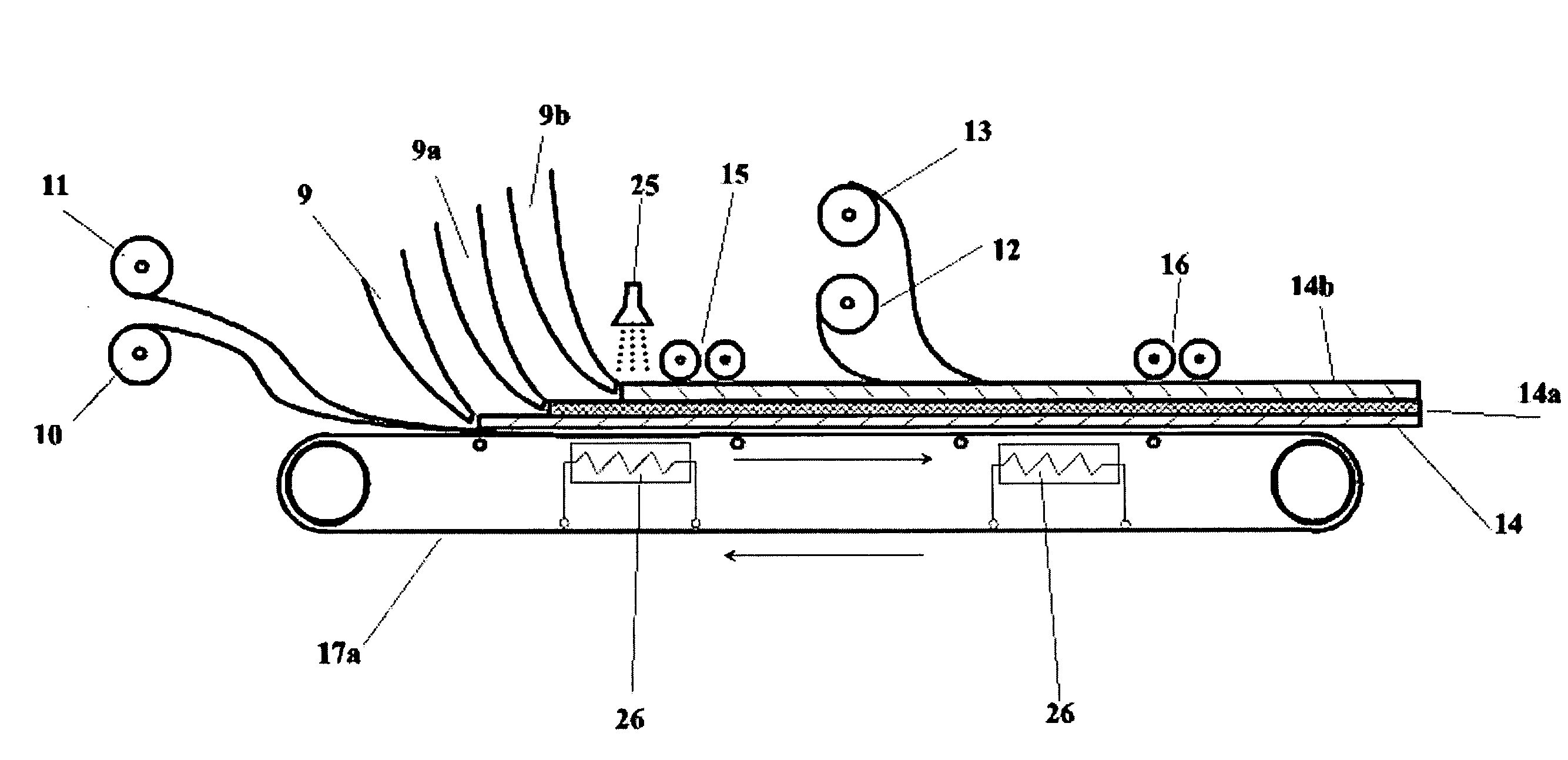

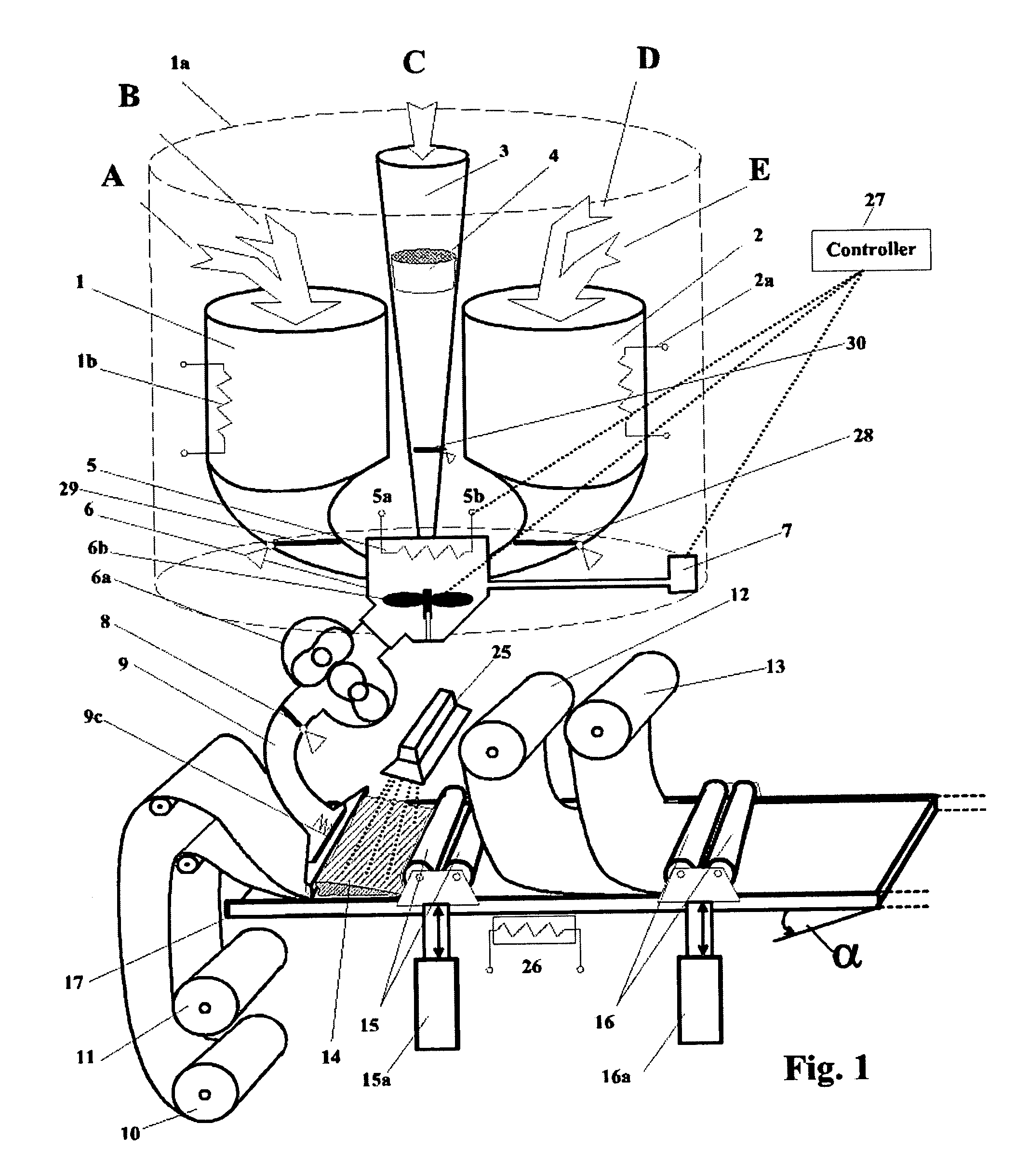

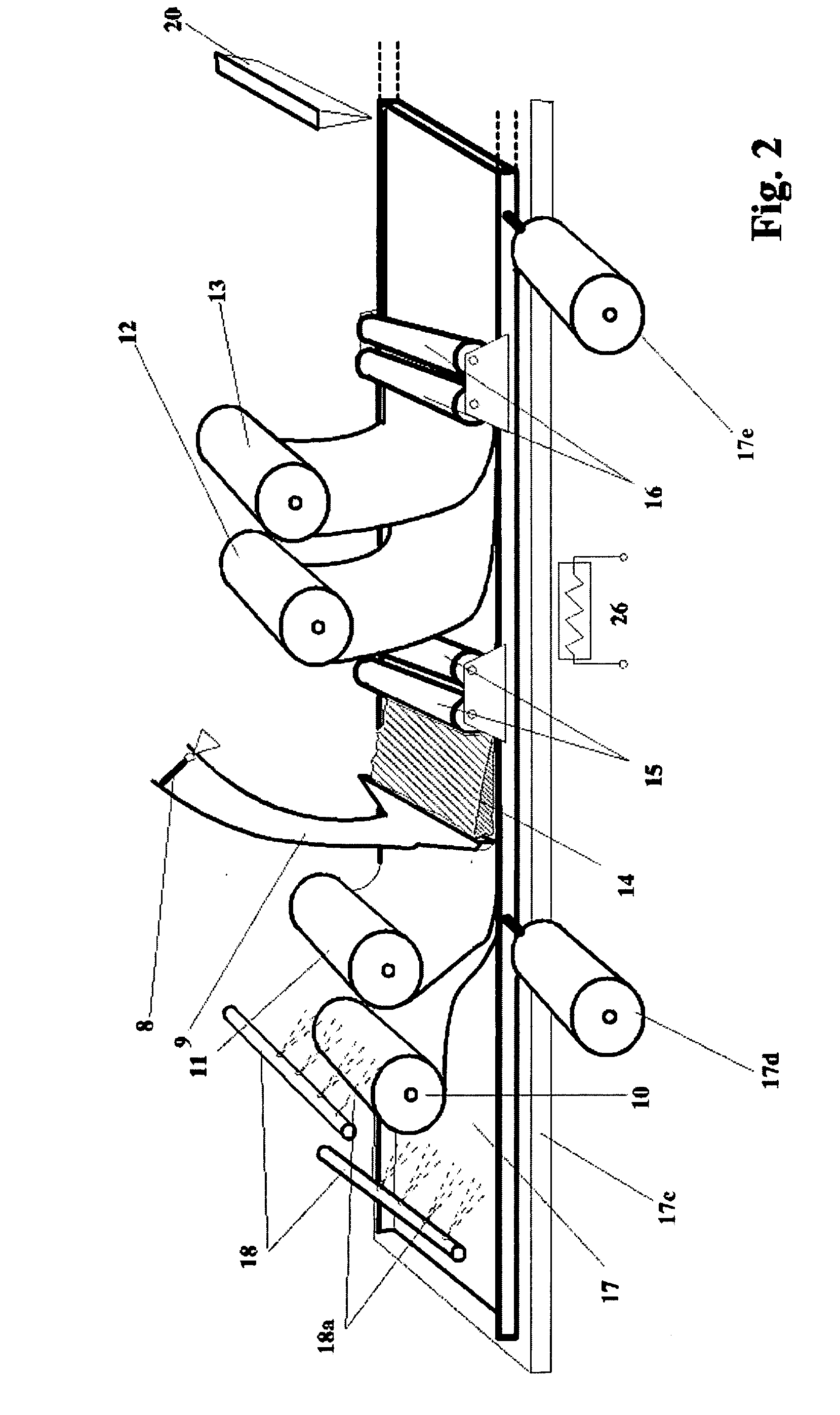

[0028]The following description is provided in relation to several embodiments which may share common characteristics and features. It is to be understood that one or more features of any one embodiment may be combinable with one or more features of the other embodiments. In addition, any single feature or combination of features in any of the embodiments may constitute additional embodiments. 100291 Referring now more particularly to the drawings in which like reference numerals indicate like parts throughout the several views, FIGS. 1-6 are schematic illustrations of a high-performance environmentally friendly building panel and related manufacturing methods in accordance with an example embodiment.

[0029]In FIG. 1, a preferential manufacturing method for the high-performance environmentally friendly building panel is shown. In this Figure a main reactor I a represents a controlled chemical system wherein different chemical compounds may be mixed in distinct tanks 1, 2, and 3. Tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com