Transport container system for goods, especially for fruit and vegetables

a technology for transporting containers and goods, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of varying the size of goods, not being able to quickly change the size of transport containers, and being expensive to produce, so as to facilitate the stacking of transport containers and reduce the volume, the effect of preventing the system from shifting during transpor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

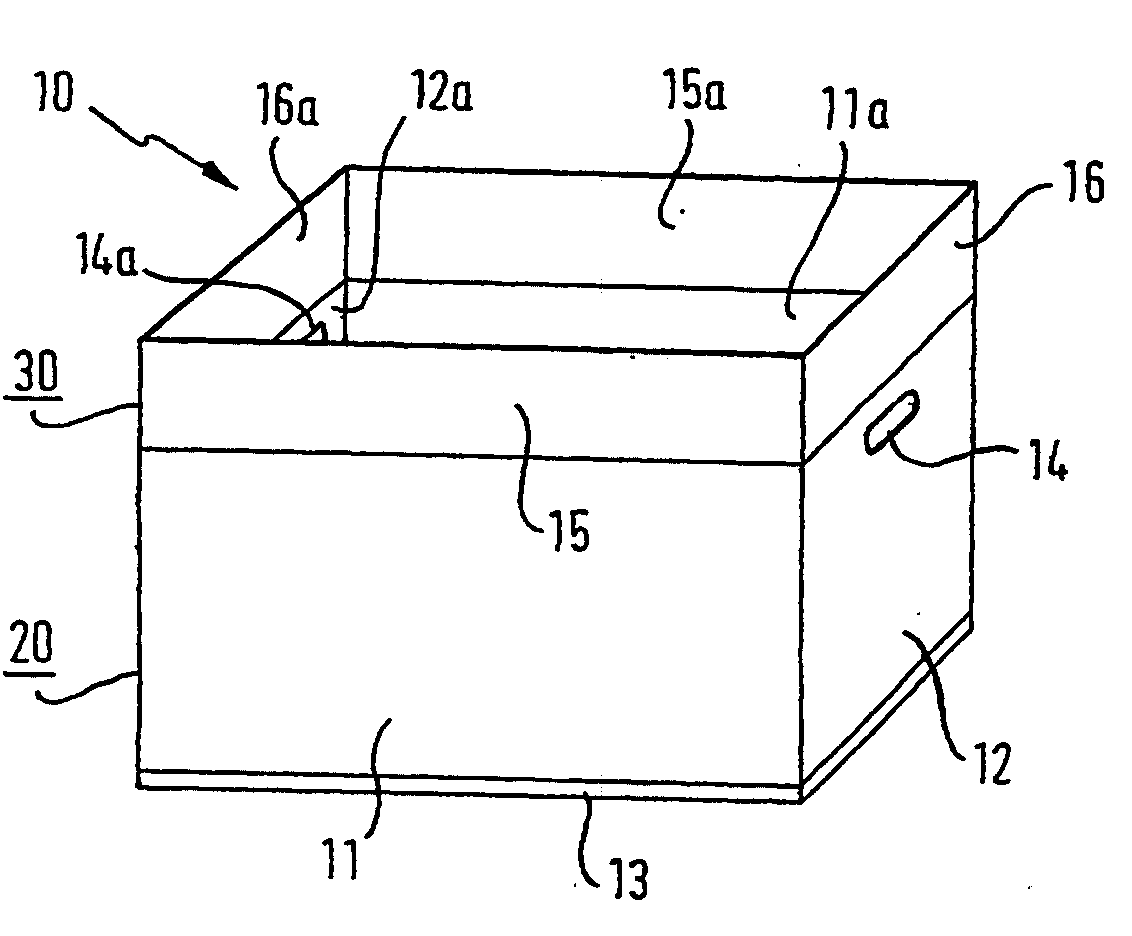

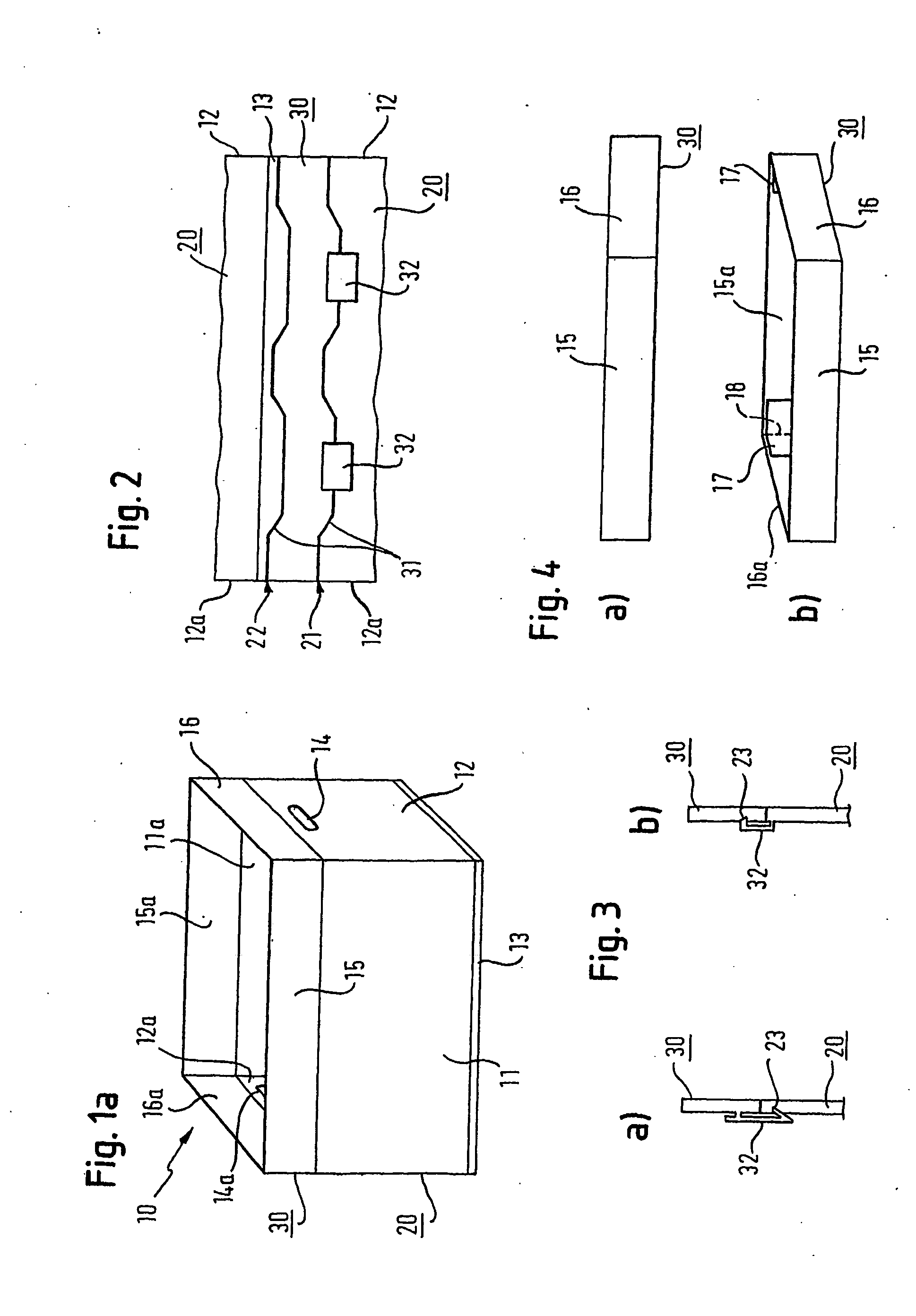

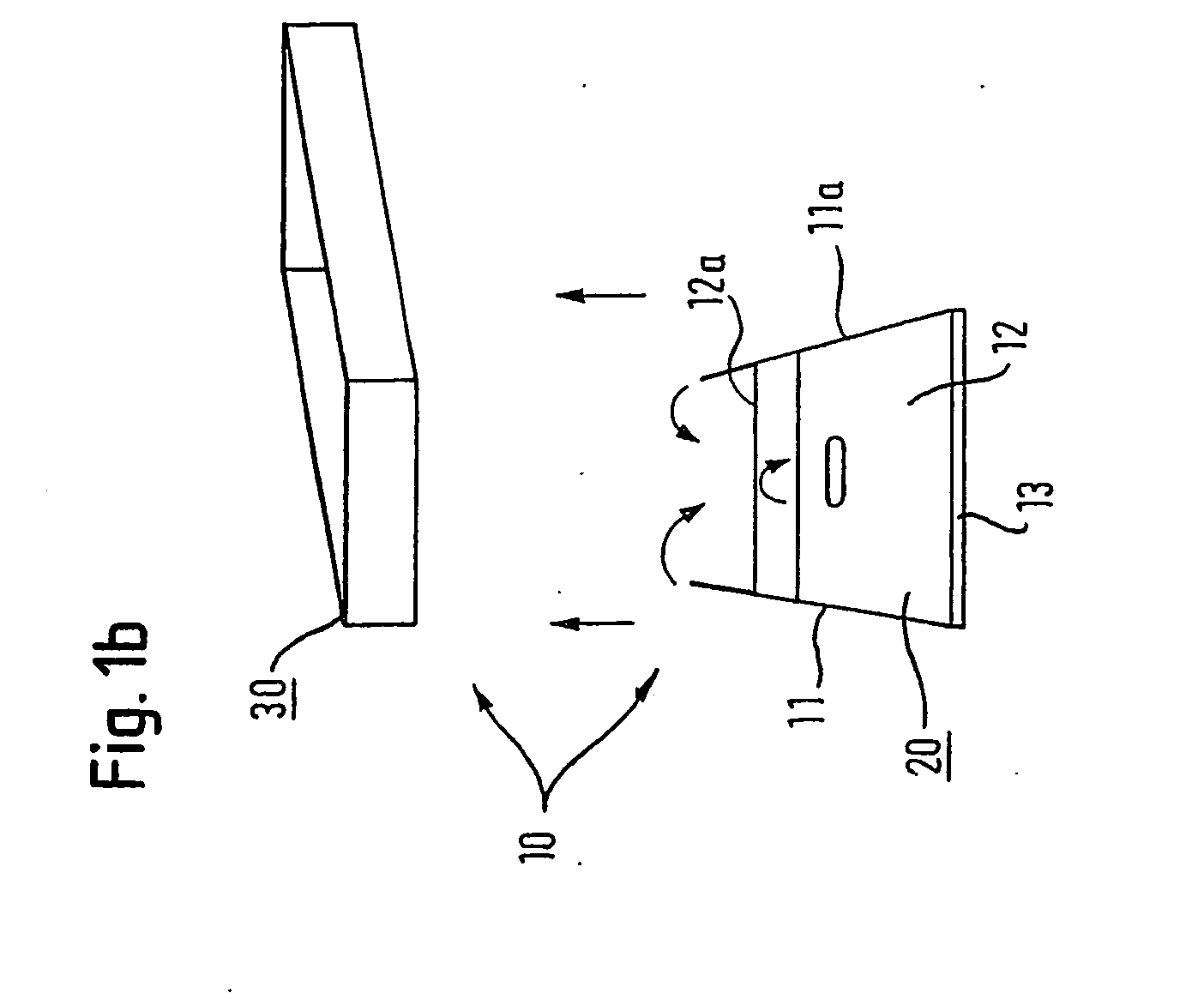

[0025]FIG. 1a is a perspective representation of an embodiment of an inventive transport container system 10. The transport container system 10 illustrated in FIG. 1a comprises a non-foldable or foldable transport container 20 and a top 30. The transport container 20 of the inventive transport container system 10 has a rectangular bottom 13 and two largely parallel lateral wall parts 11 and 11a as well as two largely parallel lateral walls 12 and 12a. The lateral wall parts 11, 11a, 12, 12a are foldable relative to the interior surface of the bottom 13 of the transport container 20, as illustrated in FIG. 1b.

[0026]FIG. 1a illustrates a non-foldable or the unfolded condition of a foldable transport container 20, whereby the lateral wall parts 11, 11a, 12, 12a are at a 90° angle to the interior surface of the bottom 13 of the transport container 20. In the upper area the two lateral wall parts 12 and 12a have handle recesses 14, 14a that facilitate ease of transport for the transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com