Continuous steam pyrolysis apparatus and pyrolysis furnace therefor

a technology of pyrolysis furnace and continuous steam, which is applied in the direction of charging-distribution device combination, products, educts, etc., can solve the problems of low resource utilization factor, poor quality of recycled rubber, inappropriateness, etc., and achieve limited processing speed and low resource utilization factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

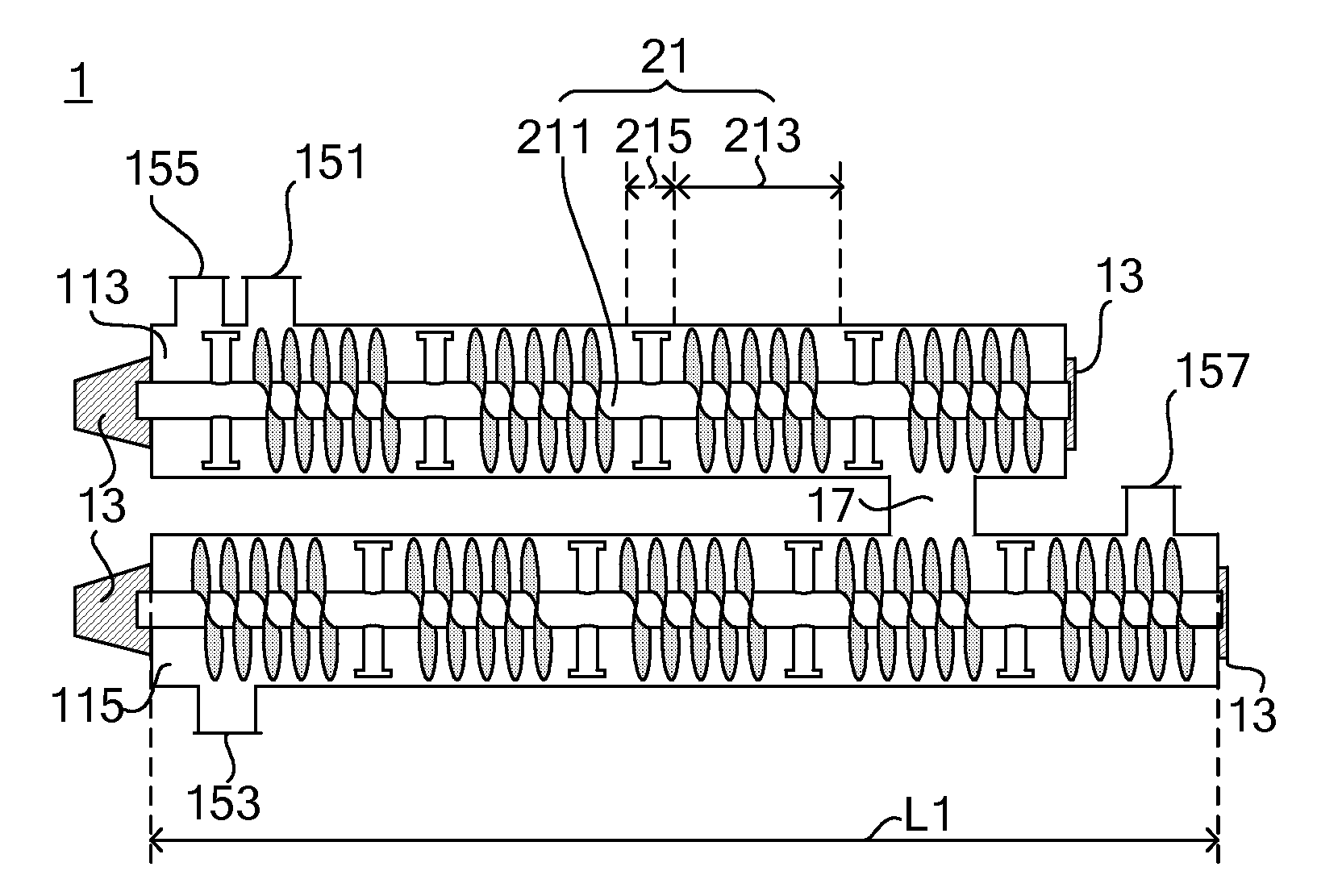

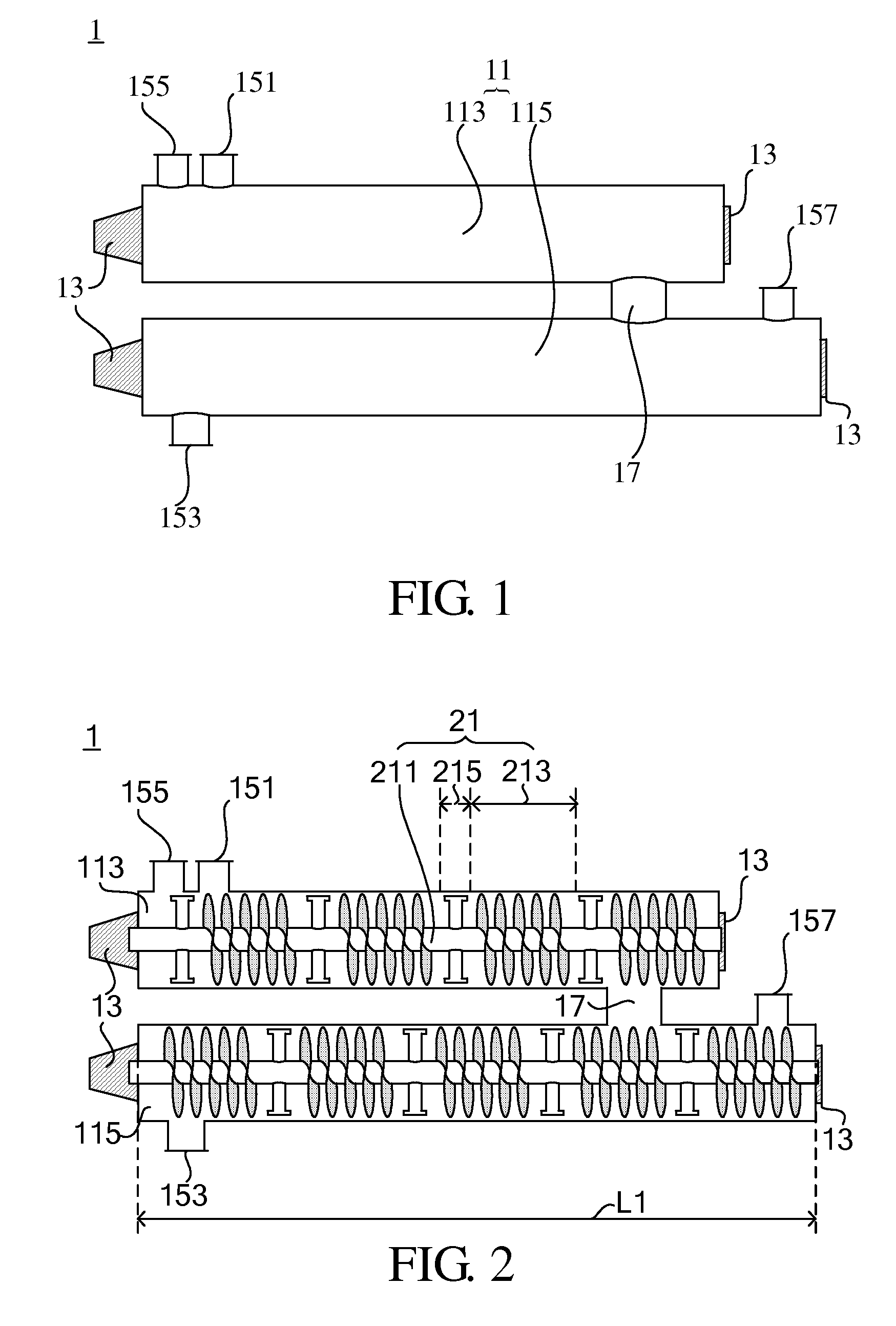

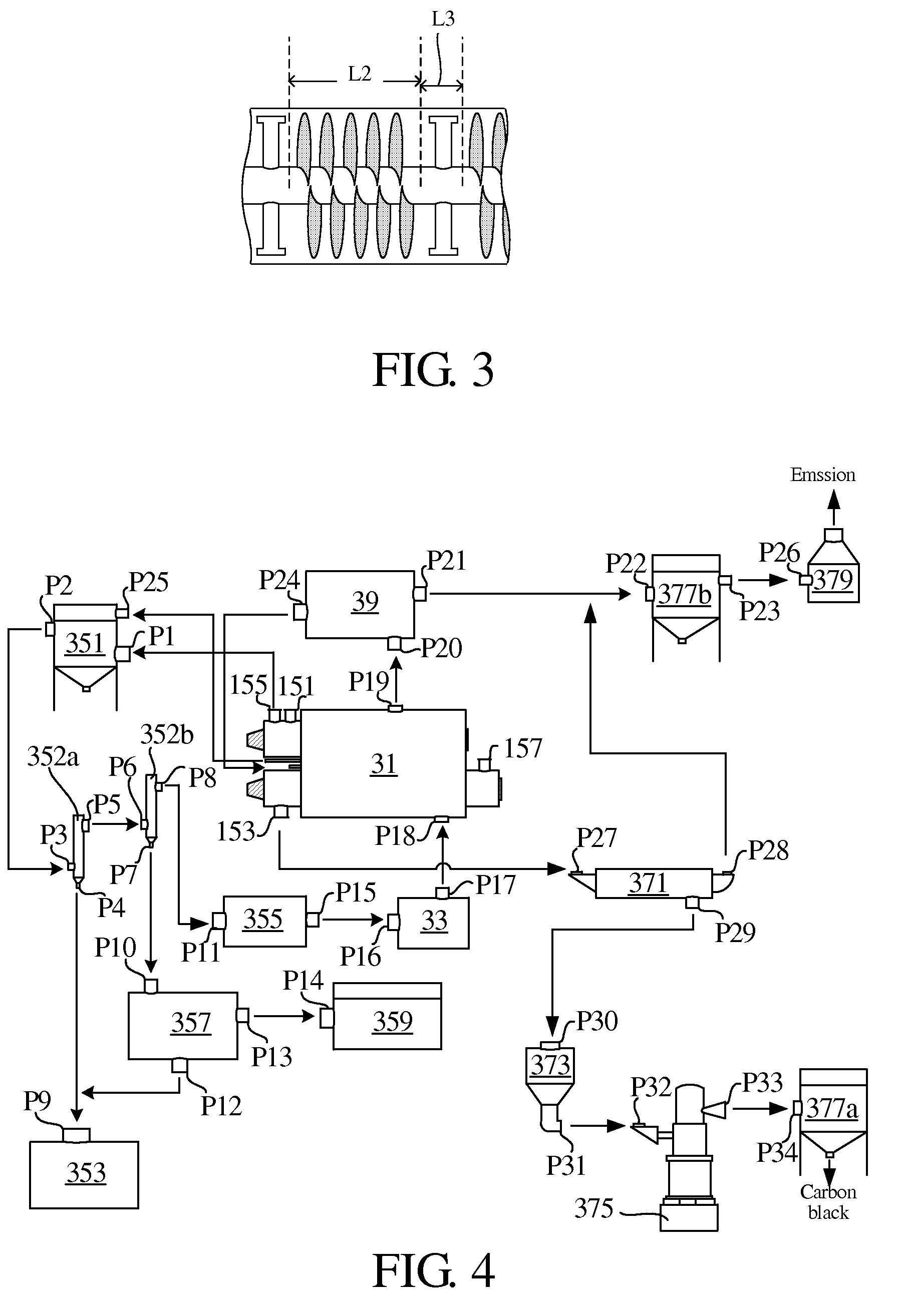

[0019]The pyrolysis furnace of the present invention comprises a reaction chamber with a charge opening and a discharge opening, and one or more axial transporting structures installed in the reaction chamber. Each of the transporting structures has a central axis, and comprises a plurality of spiral structures and a plurality of paddle structure disposed along the central axis direction. Accordingly, one or more spiral segments consisting of the screw structures and one or more paddle segments consisting of the paddle structures are formed. Each of the spiral / paddle structures has the same or different spacing from neighboring spiral / paddle structures. Preferably, each of the paddle segments is substantially identical in length, and each of the spiral segments is substantially identical in length. In an embodiment, each of the transporting structures comprises a plurality of spiral segments and a plurality of paddle segments that are alternately arranged with each other.

[0020]The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com