Ducted fan with inlet vanes and deswirl vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

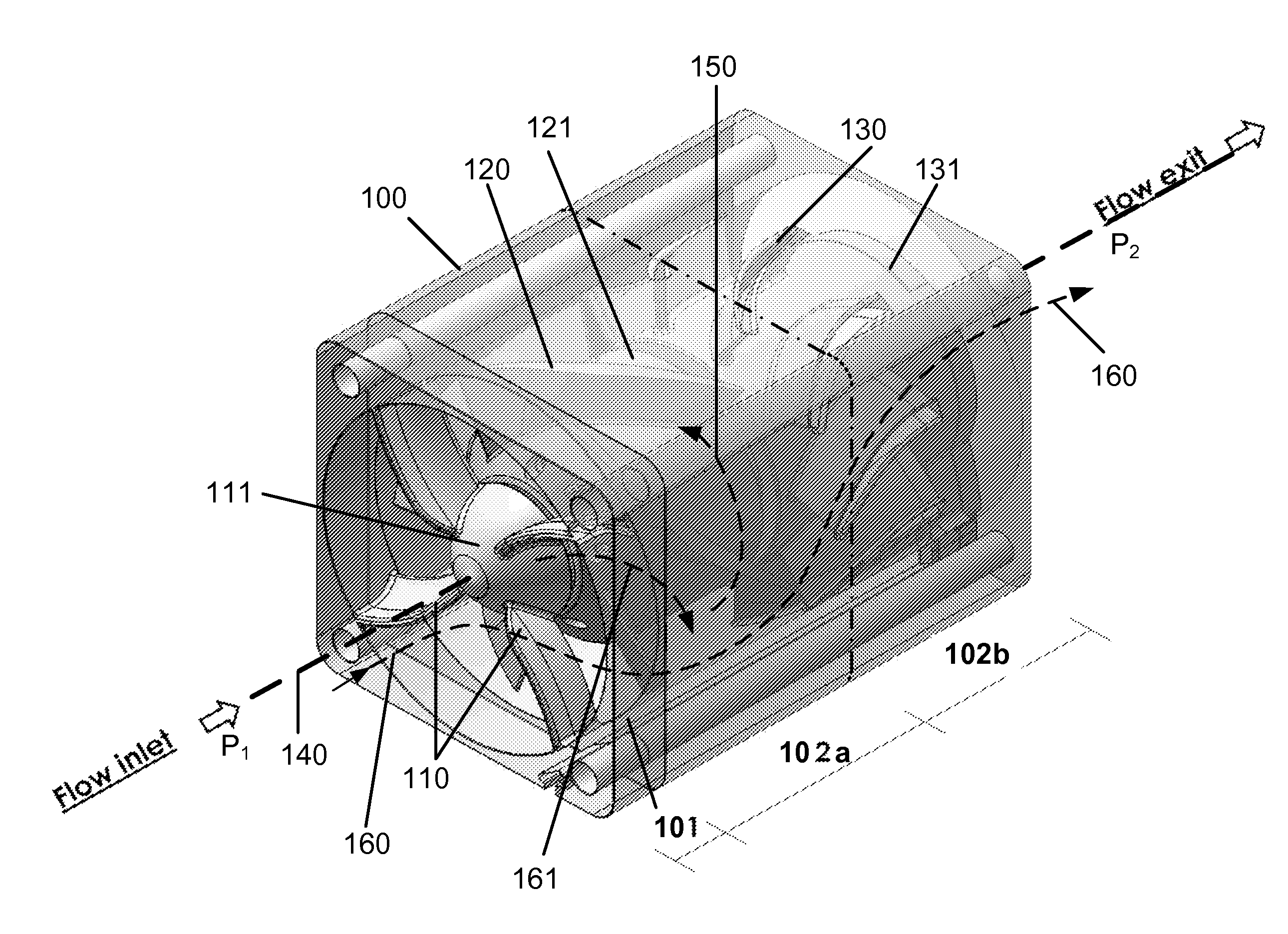

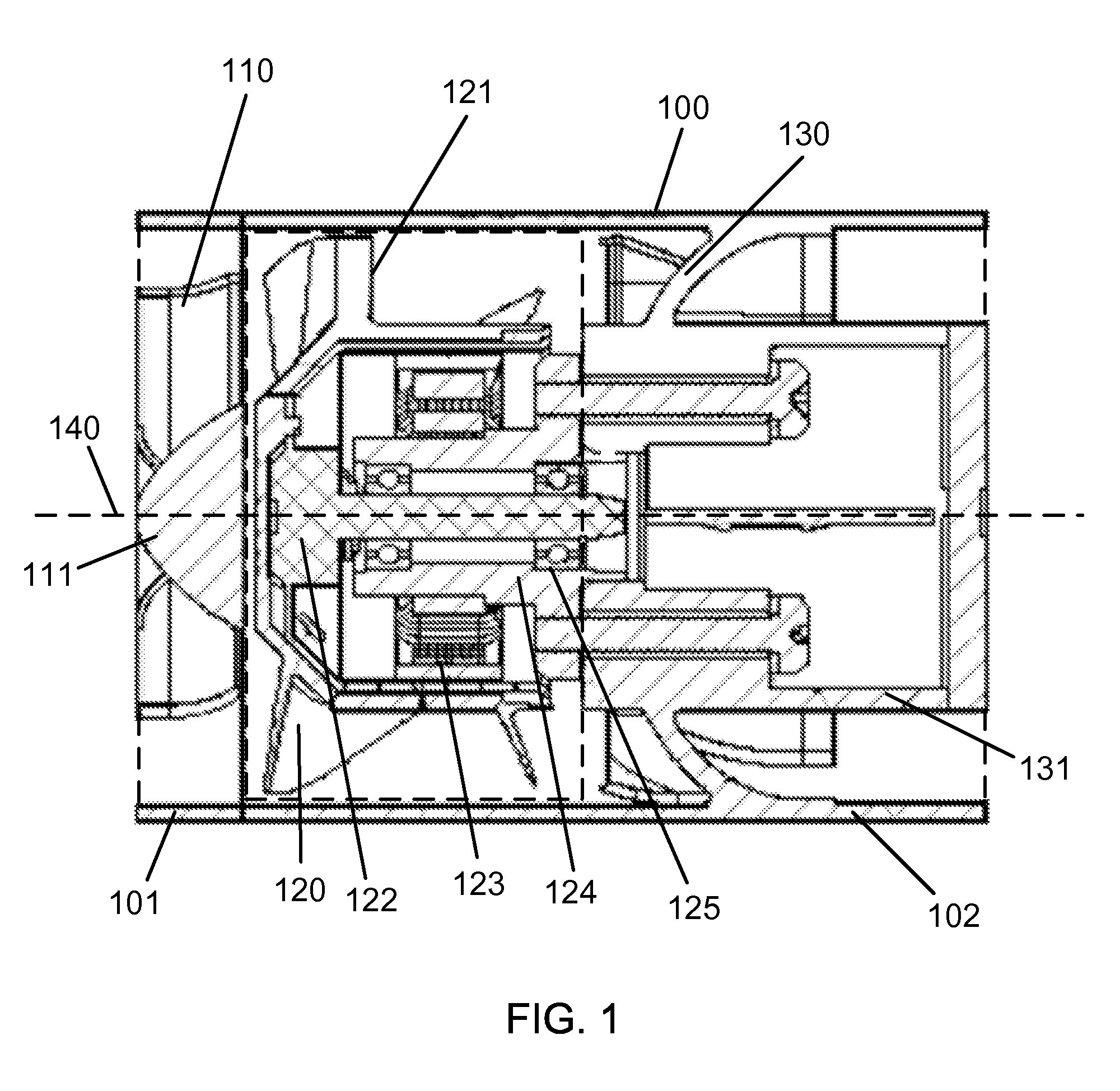

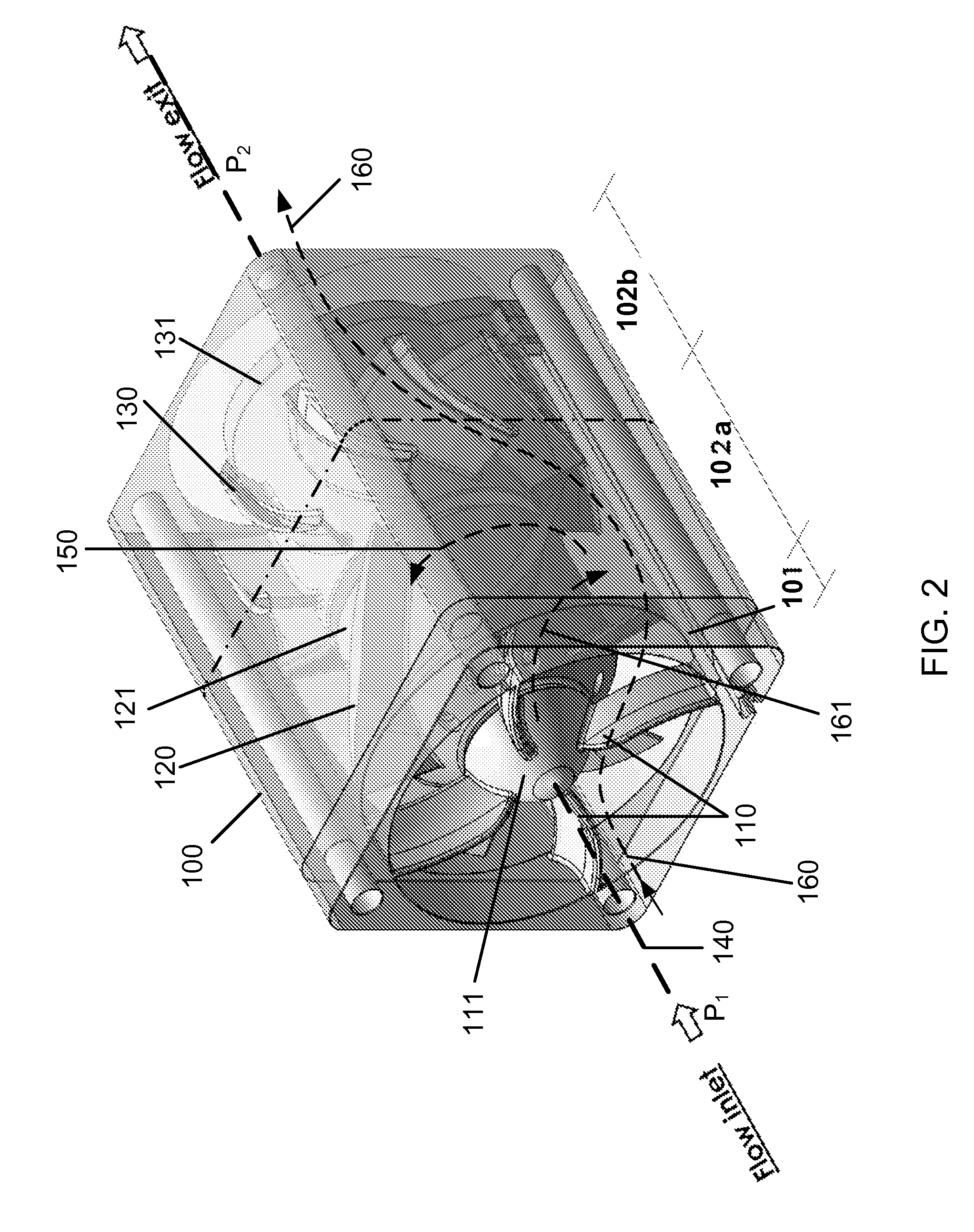

[0016]FIG. 1 is a schematic cross-sectional view of a ducted fan apparatus according to an embodiment of the present invention. This diagram is merely an example, which should not unduly limit the scope of the claims herein. One of ordinary skill in the art would recognize many variations, alternatives, and modifications. As shown, a fan apparatus includes three sets of blades sequentially disposed within a ducted housing 100 which has an interior surface enclosing an interior volume of space. In one embodiment, the ducted housing 100 includes a first section 101 and a second section 102 and is substantially symmetric around an axis of rotation 140. In one example, the first section 101 is located upstream of the second section 102 when the ducted fan apparatus is used for processing a flow of fluid including air. The interior volume of space is a cylindrical shape around the axis of rotation 140. In another example, the interior volume of space within the first section can have a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com