Fan blade

a technology of fan blades and blades, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of blade damage, blade efficiency drop at cruise, and increase in efficiency at cruise, so as to reduce engine noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

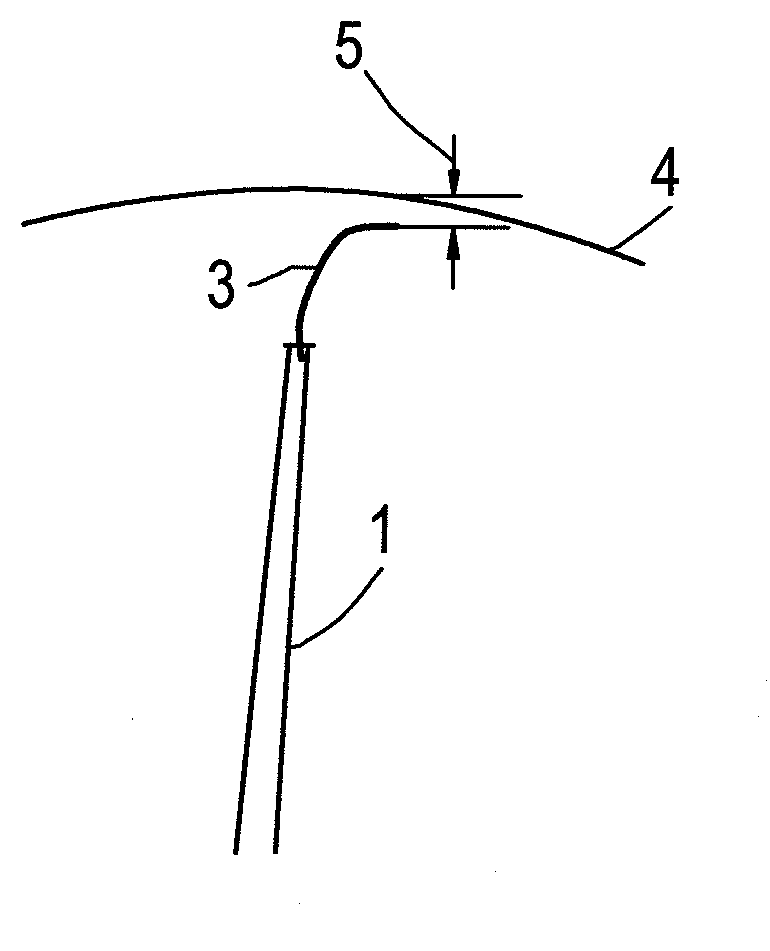

[0024]FIG. 1 shows schematically the tip of a fan blade 1. Slotted into a keyway 2 which runs along the radially outer edge of the blade is a strip sealing element 3 formed of a flexible material, such as plastic, rubber (e.g. silicone rubber) or coated metal foil. The sealing element can be removably replaceable when worn or damaged.

[0025]The keyway 2 can be formed in the body of a composite or a metallic blade, or can be formed by a separate part, e.g. facing side plates, attached to the tip of such a blade.

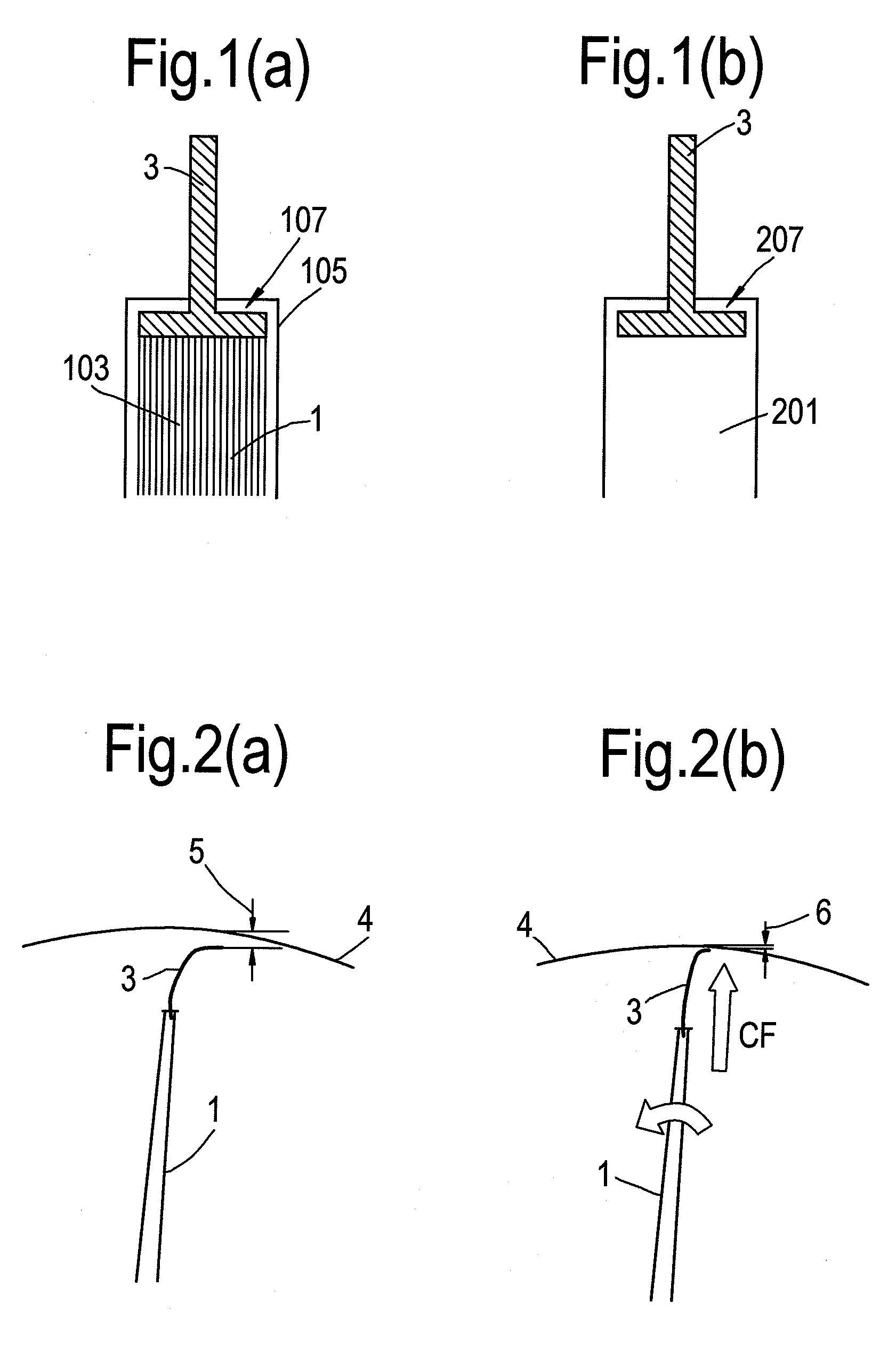

[0026]FIGS. 2(a) and (b) show schematically the operation of the sealing element 3. In

[0027]FIG. 2(a), the engine is stationary. Sealing element 3 has a curved cross-section profile, and there is a relatively large cold build clearance 5 between the radially outer edge of the sealing member 3 and the fan case 4. In FIG. 2(b), the blade is now rotating in the direction indicated by the curved arrow. A centrifugal force (CF) straightens out the profile of the sealing element so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com