Recuperative Hybrid Trains using Batteries in an intermodal Container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

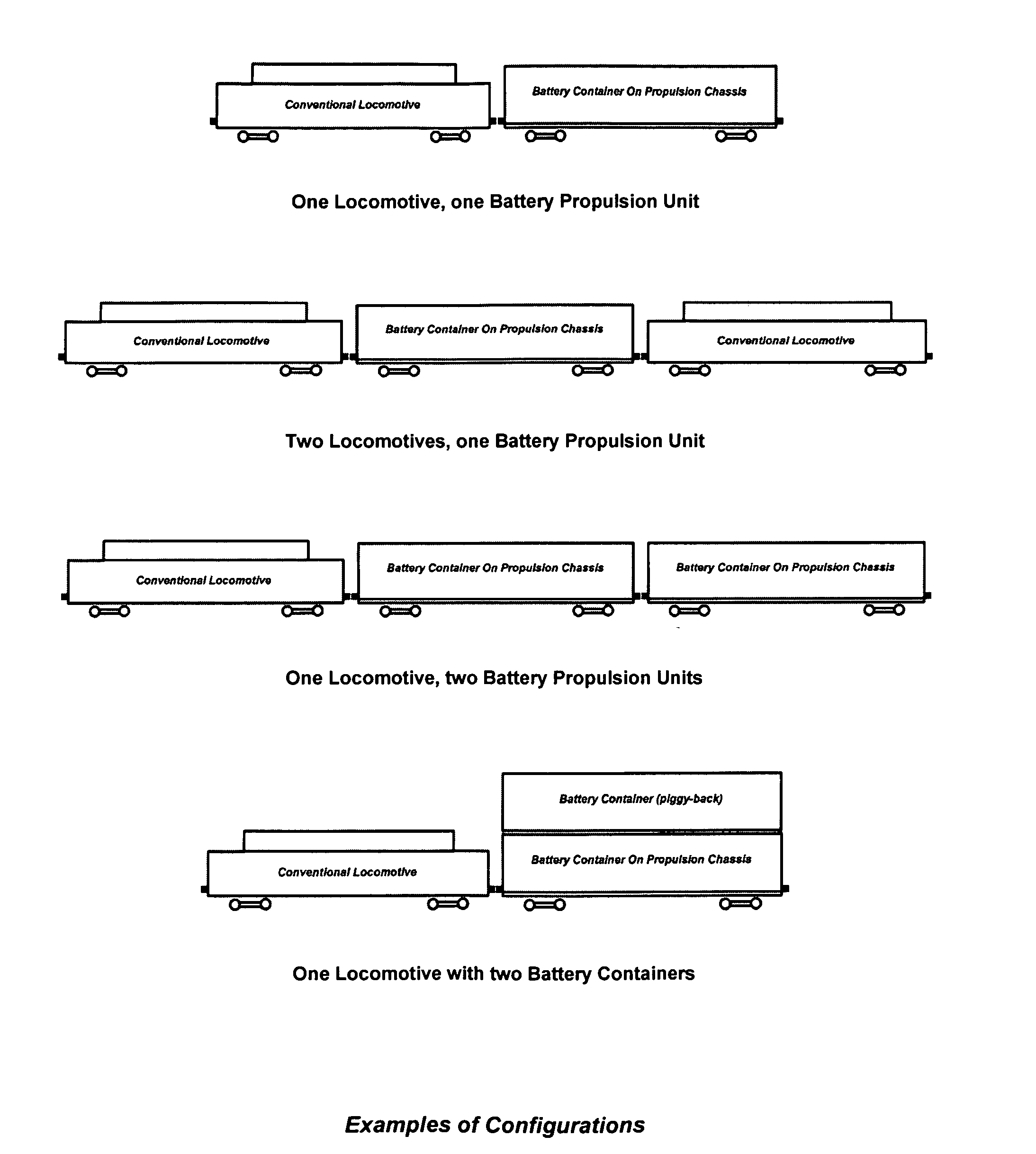

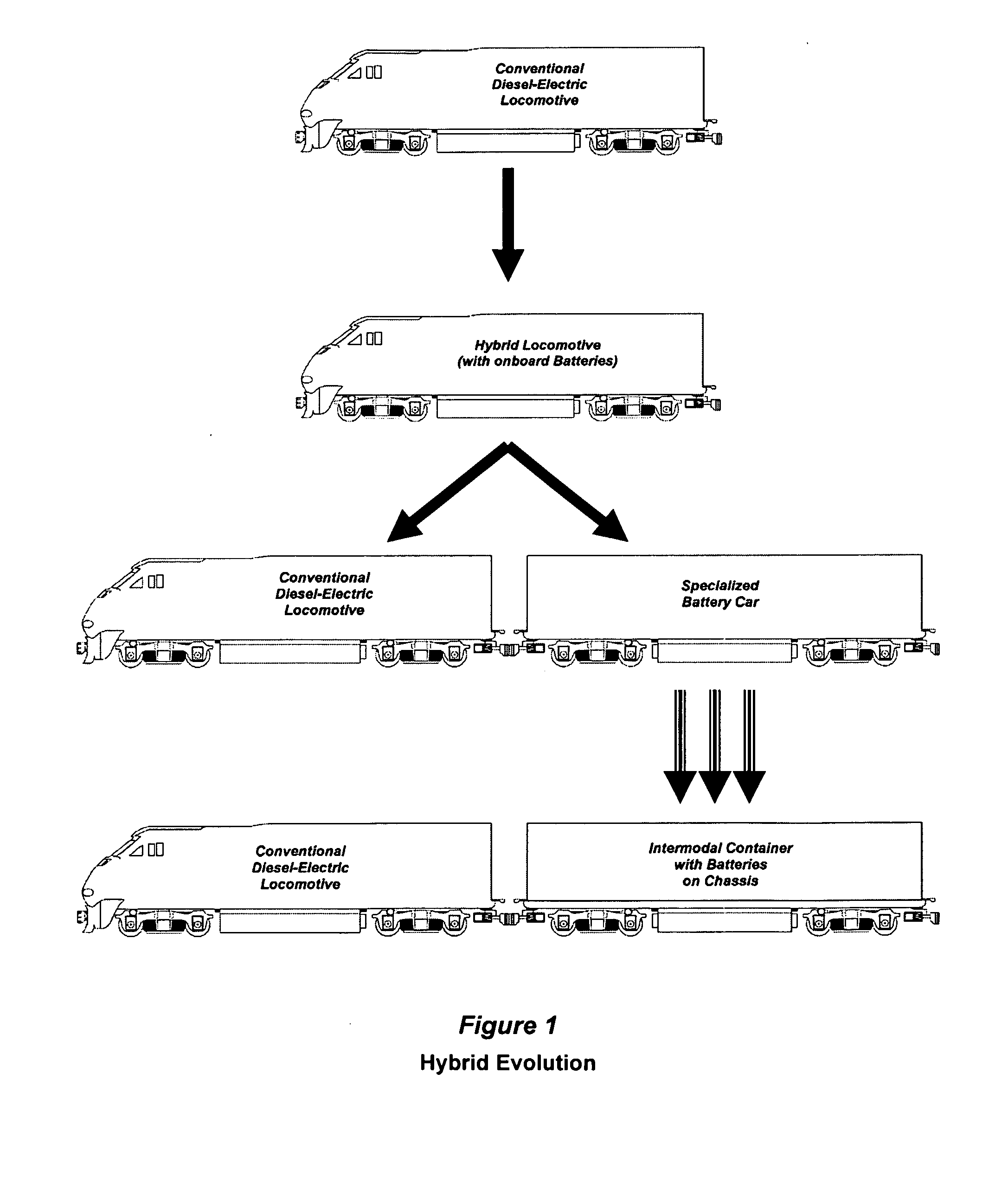

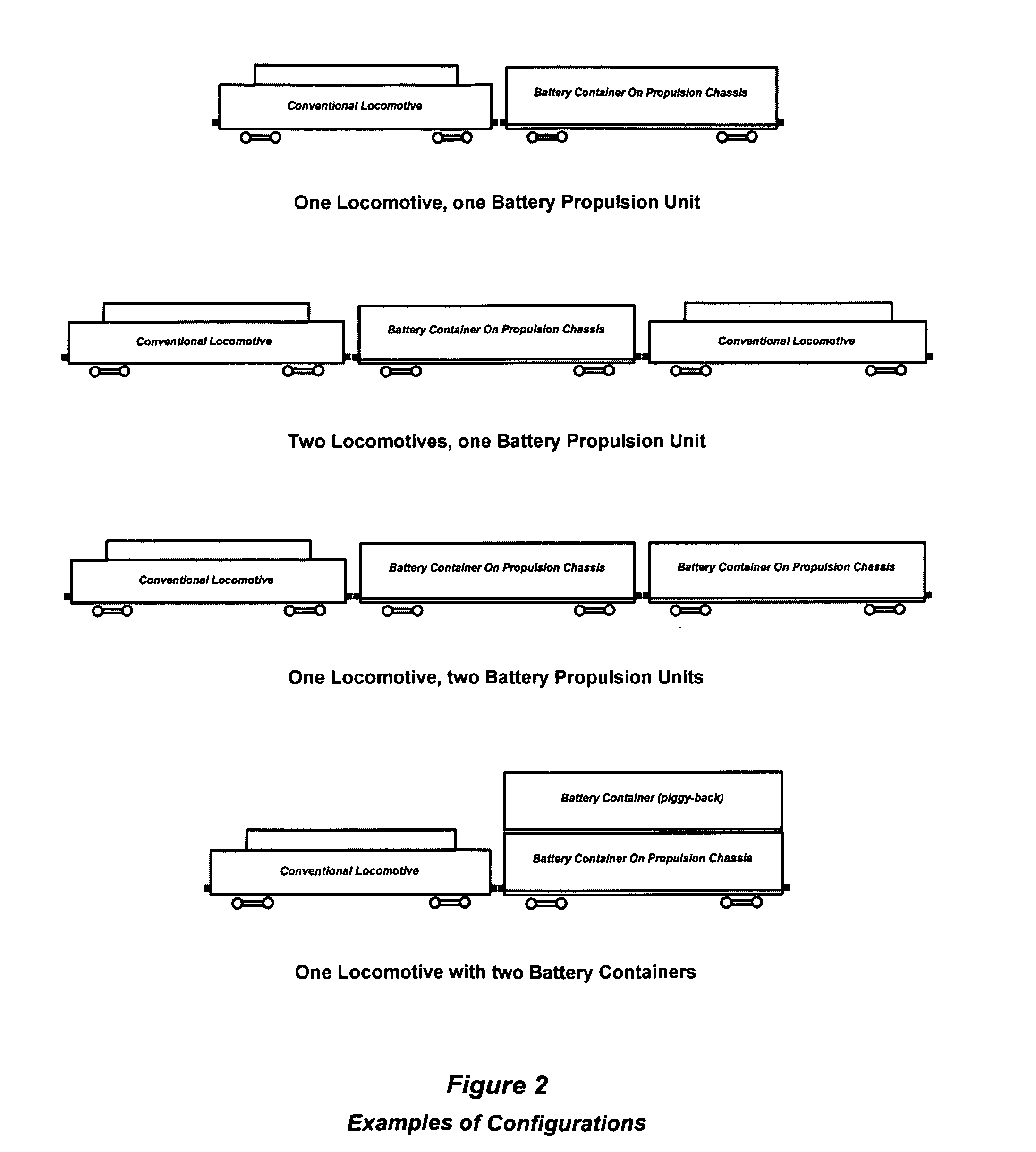

[0016]The present invention relates generally to hybrid versions of diesel-electric locomotives and improves the previous art (see FIG. 1) by placing such batteries in standard intermodal containers (referred to in this document as battery containers) which can easily be moved by readily available cranes built for the purpose of moving freight containers (see FIG. 3). Such battery containers can be placed on a freight train chassis in different configurations (as shown in FIG. 2) to allow a variety of ratios between the number of containers and the number of locomotives to accommodate different requirements. The battery containers itself will be equipped with their own ventilation system to prevent overheating or the accumulation of unwanted fumes as well as cables with plugs to connect the container's batteries to the power grid and information network of the train and / or chassis if a chassis with motors and recuperative brakes is used. The containers will also house the power conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com