Mobile crusher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

[0016]A first exemplary embodiment of the invention will be described below with reference to the attached drawings.

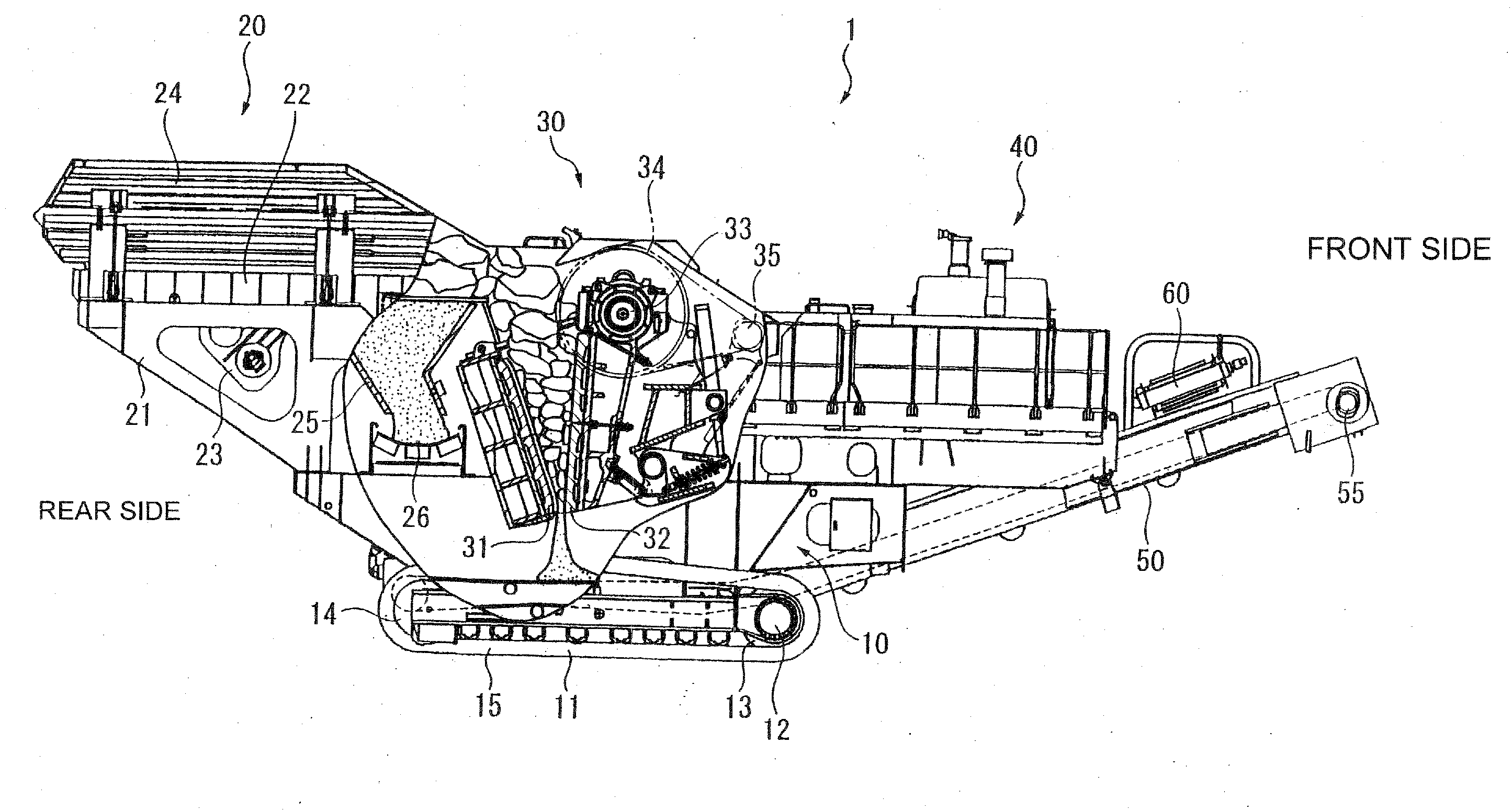

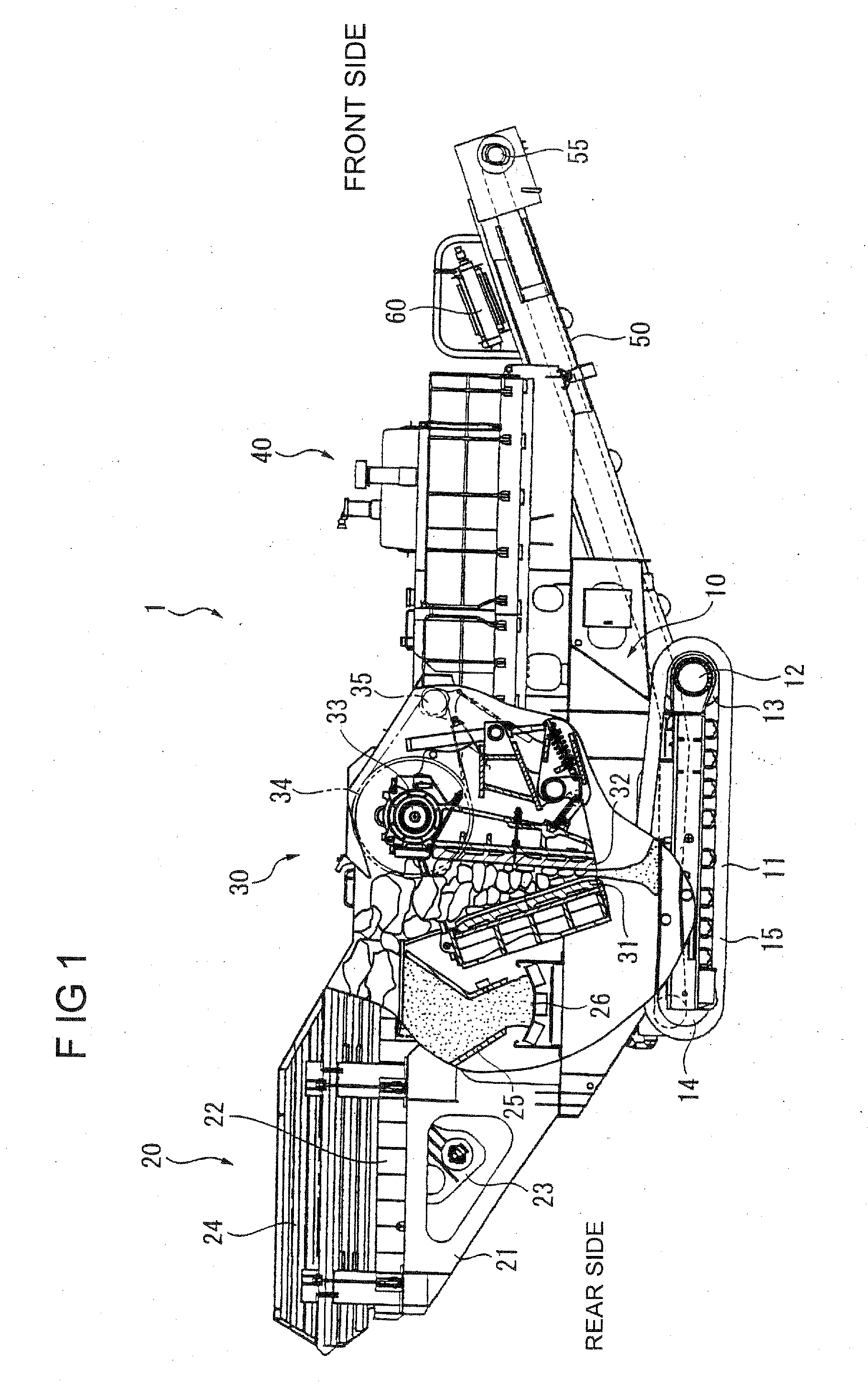

[0017]FIG. 1 is a side view showing a mobile crusher 1 according to the first exemplary embodiment. The mobile crusher 1 crushes raw materials loaded by a loader such as a hydraulic excavator and a wheel loader to produce crushed materials having a predetermined particle size.

[0018]The mobile crusher 1 includes: a main unit 10 having a pair of undercarriage members 11 (one of which is shown); a feed unit 20 provided to the rear side on top of the main unit 10 (on the left side in FIG. 1) for supplying raw materials; a crusher 30 provided to the front side of the feed unit 20 (on the right side in FIG. 1); a power unit 40 provided to the front side of the crusher 30; a discharge conveyor 50 (work implement) extending forward and obliquely upward between a pair of crawlers 15 on a lower portion of the main unit 10; and a controller 70 for controlling the discharge convey...

second exemplary embodiment

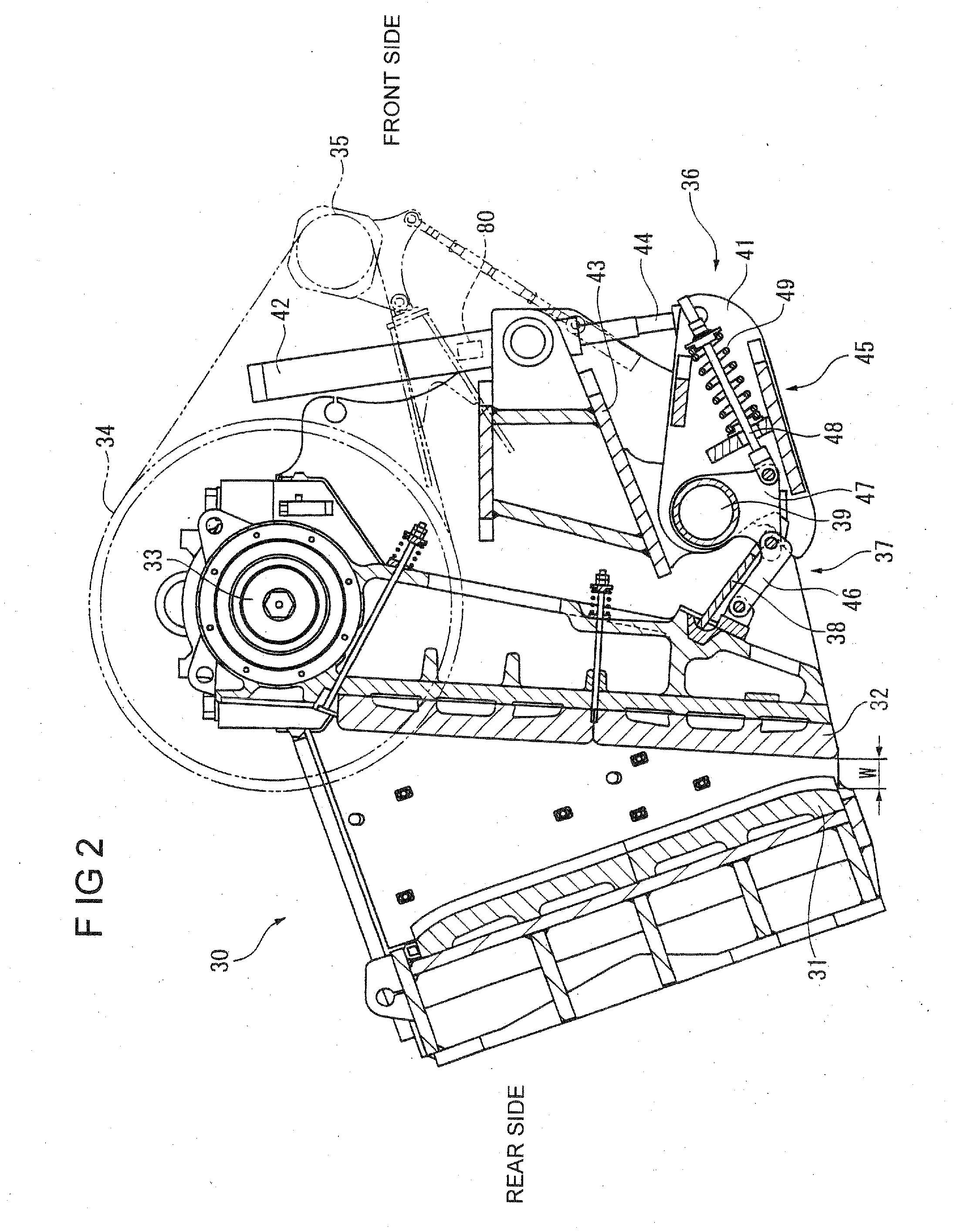

[0036]FIG. 6 is a block diagram of the controller 70 and FIG. 7 is a flow chart of the controller 70 according to a second exemplary embodiment. In the second exemplary embodiment, an outlet gap input unit 76 such as an operation panel is connected to the controller 70. A desired outlet gap W is inputted to the outlet gap input unit 76. The controller 70 controls an advancement and retraction amount of the mechanical lock hydraulic cylinder 42 to provide the outlet gap W inputted to the outlet gap input unit 76.

[0037]In the second exemplary embodiment, an operator initially inputs a desired outlet gap W to the outlet gap input unit 76 (S1). Then, the outlet gap calculator 71 of the controller 70 references the map M1, reads a rotation angle θ in accordance with the inputted outlet gap W to provide a target angle θ0, and outputs a drive command to the advancement and retraction driver of the mechanical lock hydraulic cylinder 42 so that the rotation angle θ of the mechanical lock hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com