Thin-film magnetic head with variable-volume cavity in medium-opposed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

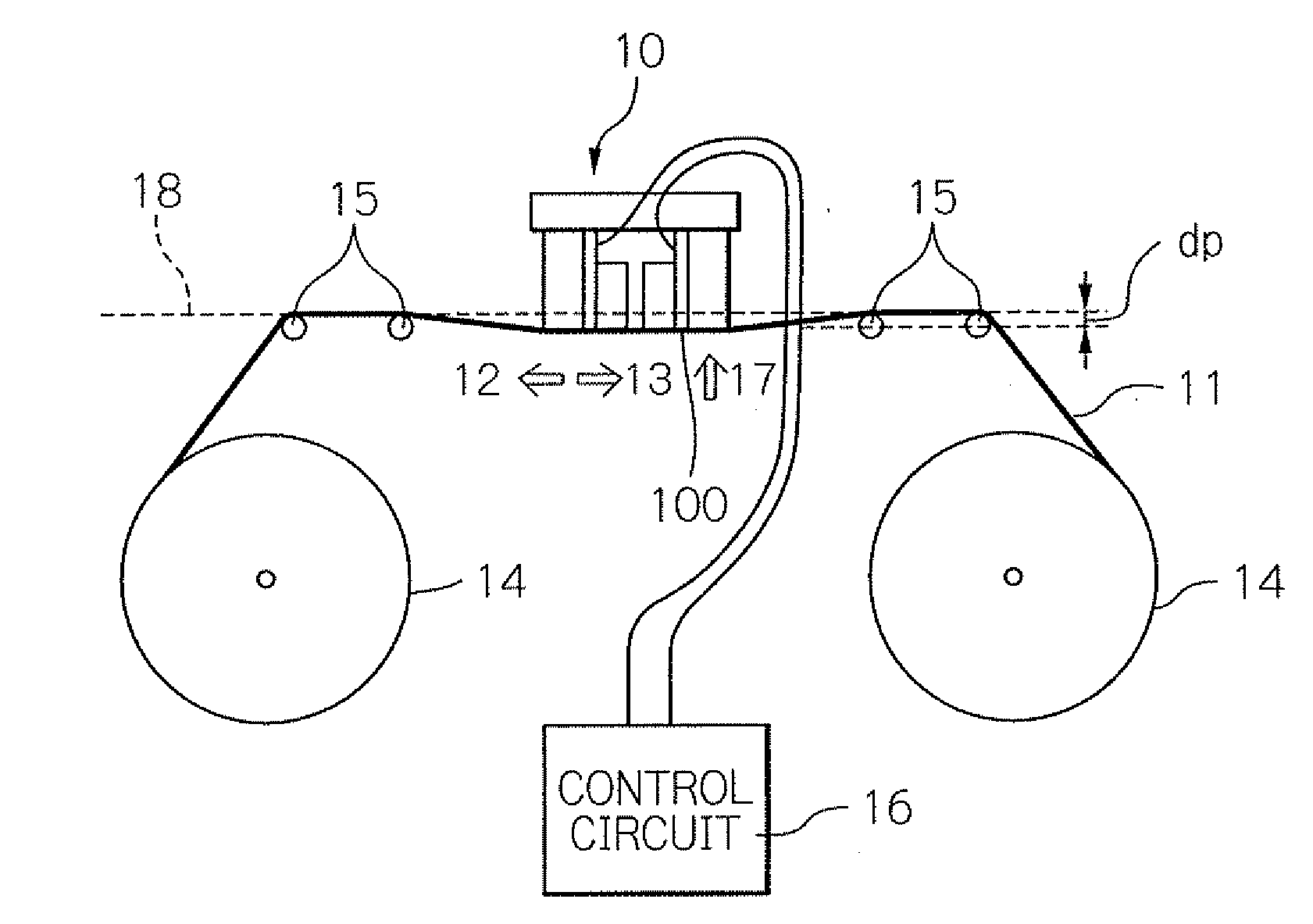

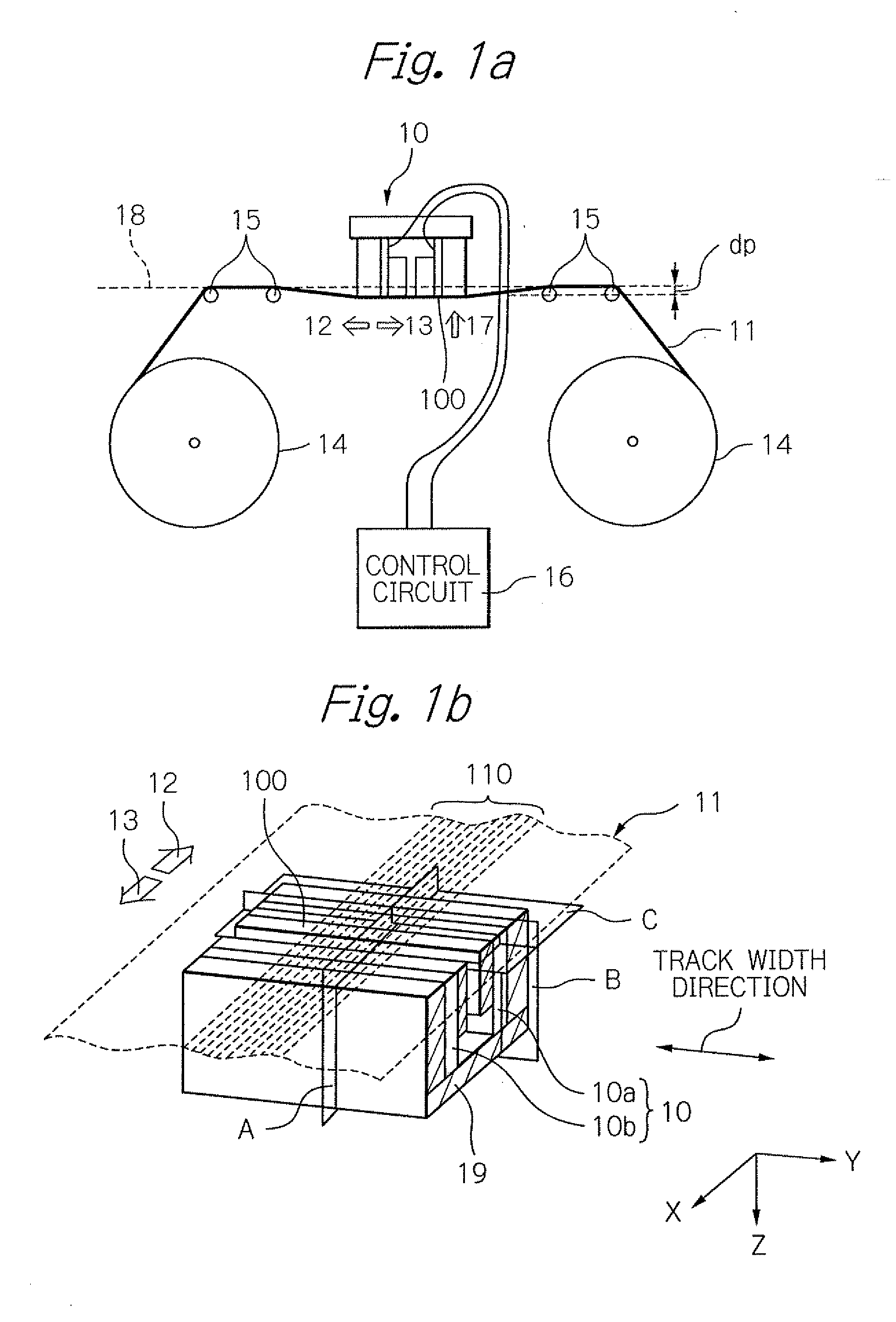

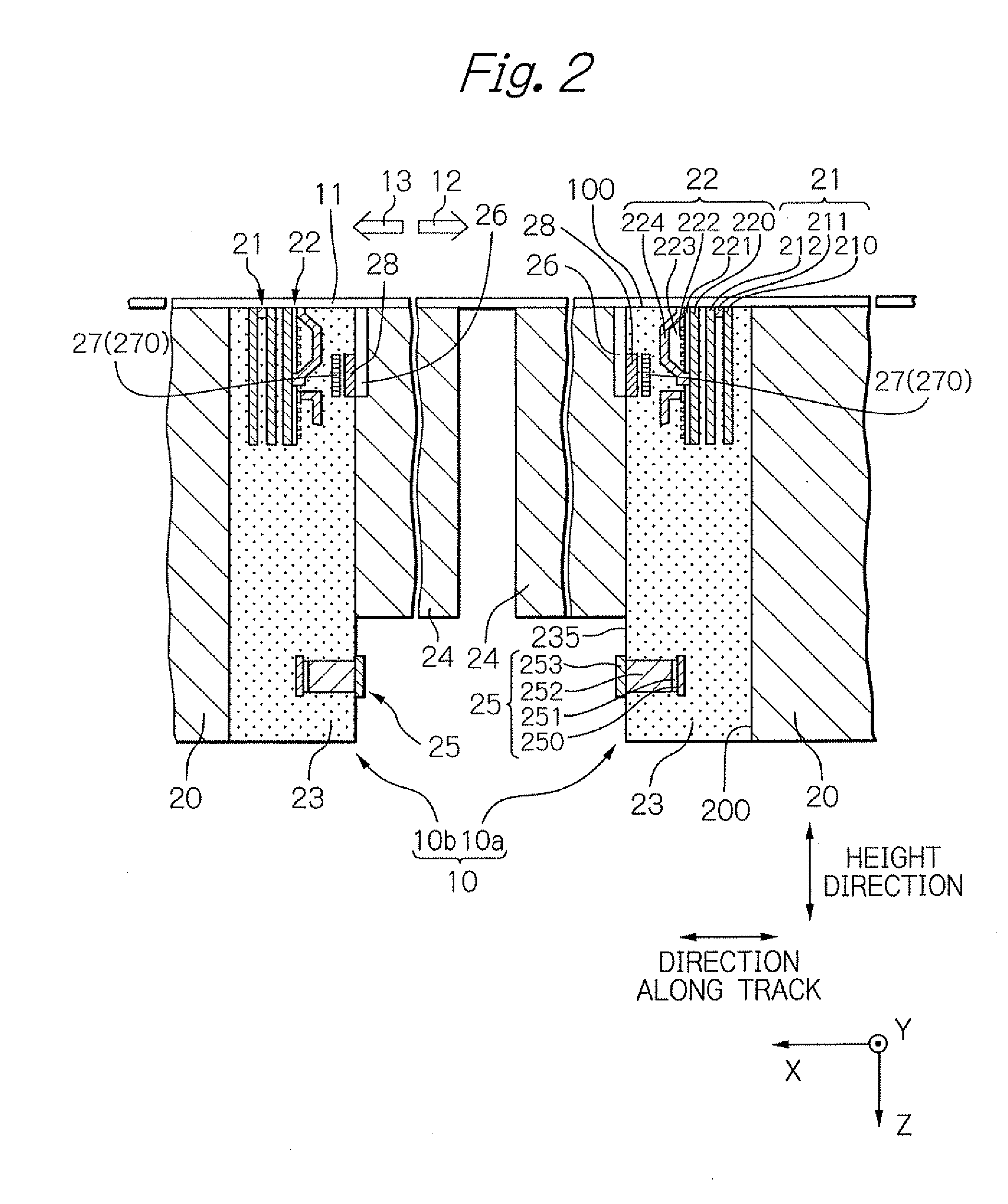

[0049]FIG. 1a shows a schematic view illustrating the main part of one embodiment of the magnetic tape apparatus according to the present invention. And FIG. 1b shows a perspective view schematically illustrating one mode of the configuration of the magnetic recording medium and the thin-film magnetic head according to the present invention.

[0050]As shown in FIG. 1a, the magnetic tape apparatus of the present embodiment includes: a tape head 10 as a thin-film magnetic head for performing read and write operations to a magnetic tape 11 as a magnetic recording medium; guide pins 15 for guiding the running of the magnetic tape 11; and a recording / reproducing and cavity-volume control circuit 16. The reference numeral 14 indicates reels for winding and unwinding (feeding) the magnetic tape 11.

[0051]The tape head 10 is provided for reading and writing data signals, whose tape baring surface (TBS) 100, which is the end surface on the magnetic tape 11 side or a medium-opposed surface (oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com