Panel Stack Safety Holder

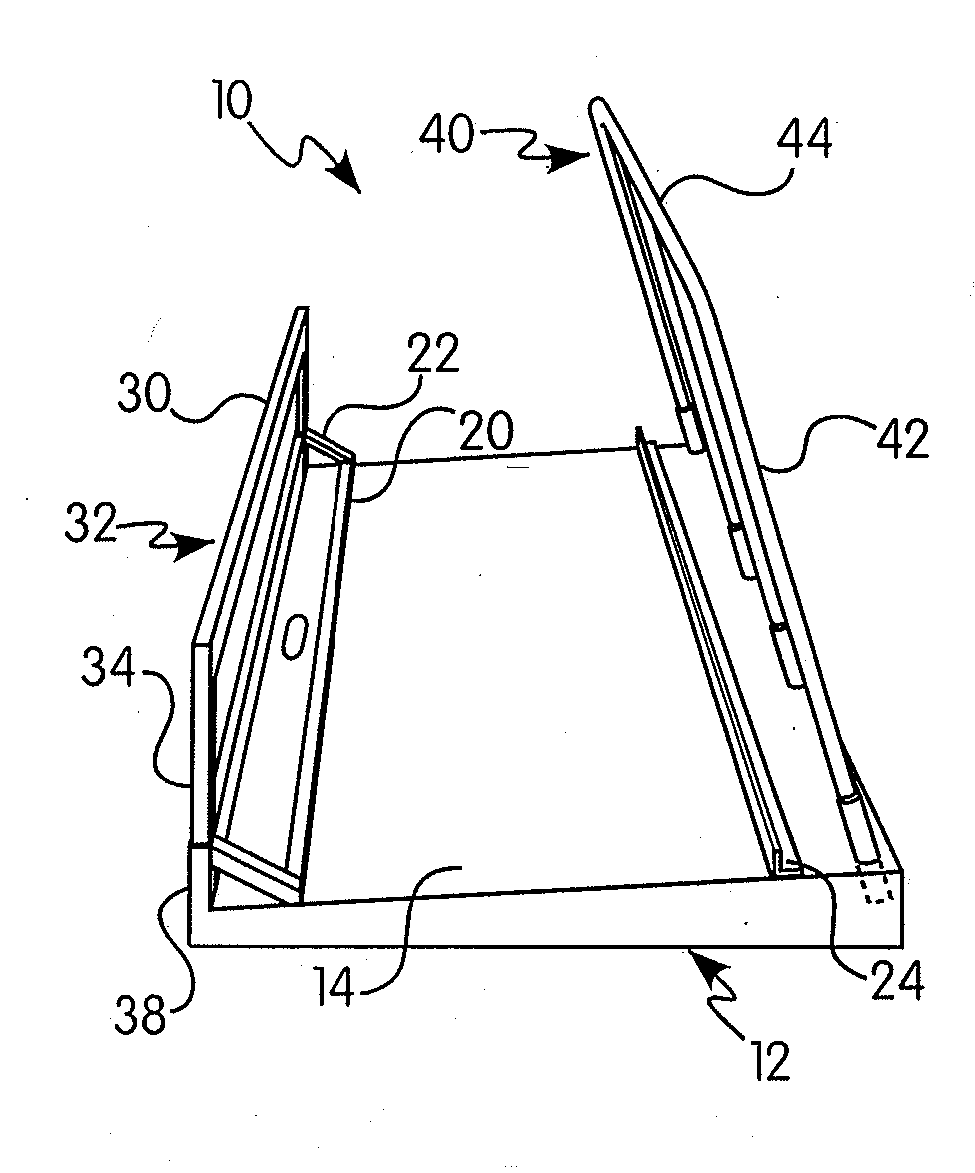

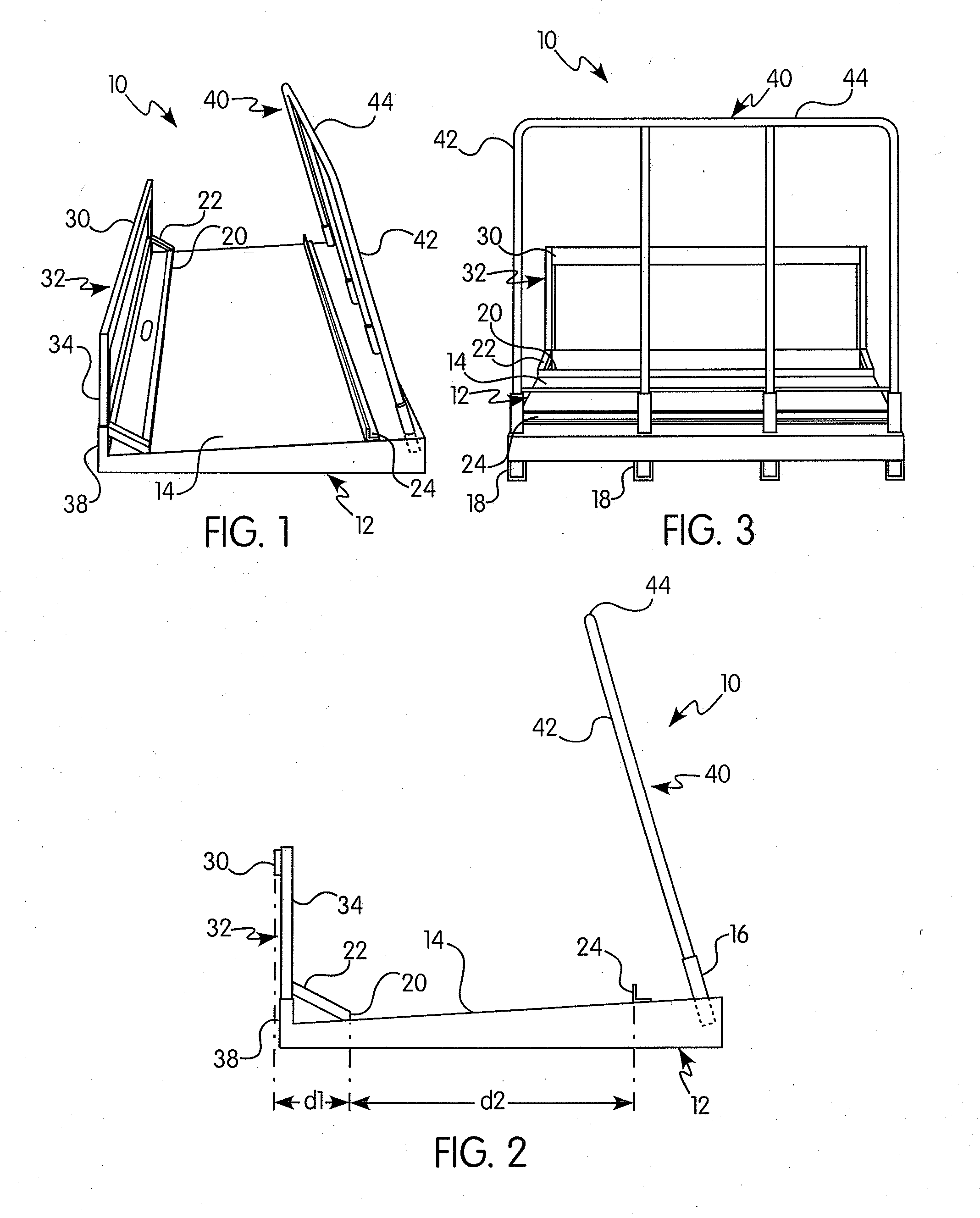

a technology for stack safety and panels, applied in the field of building construction, can solve the problems of slipping of panels to the floor, frequent back injuries, etc., and achieve the effect of preventing toppling of panels and preventing sliding of panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

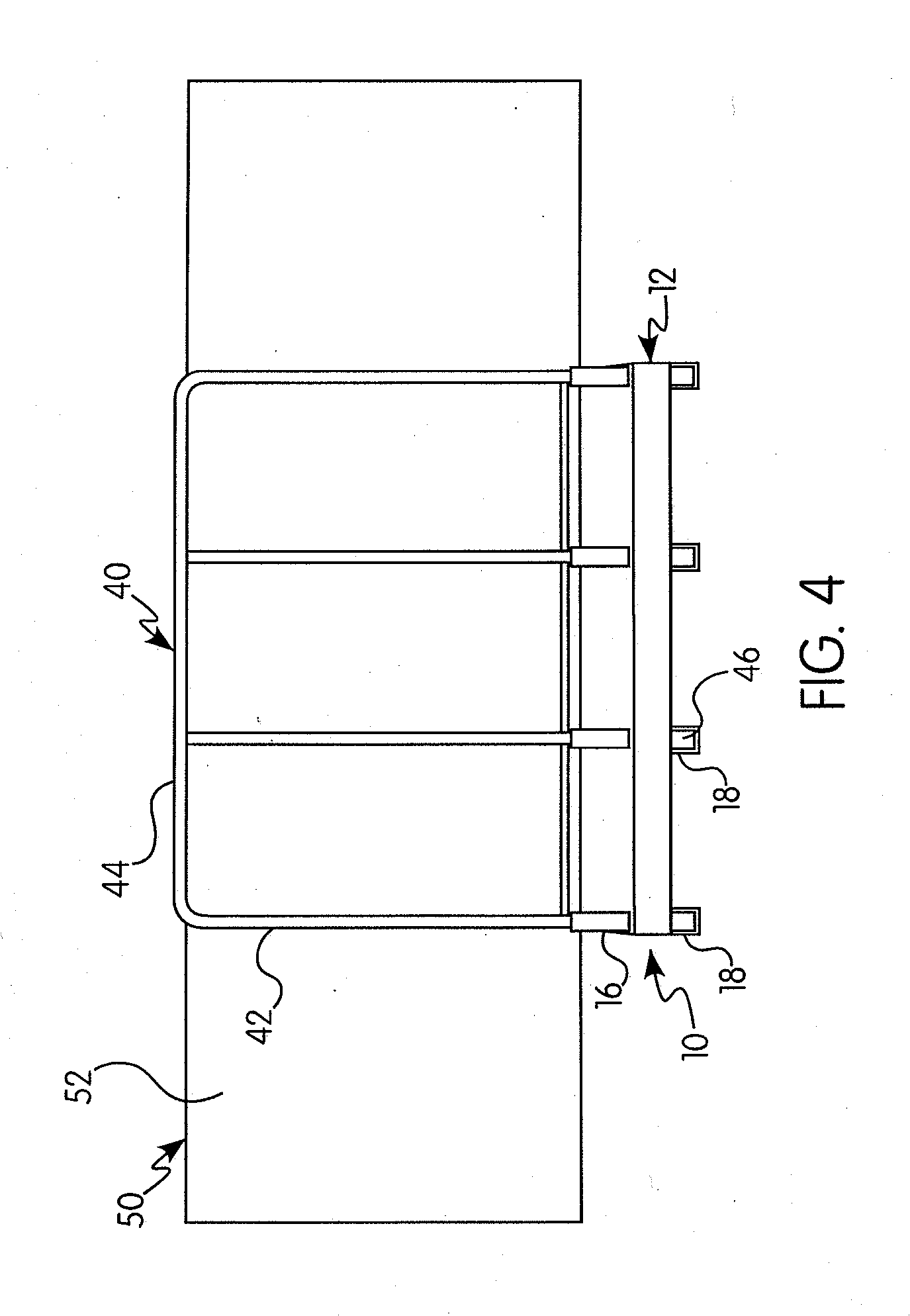

[0028]In FIG. 10, panel holder 10′ is illustrated, wherein the anti-tilt railing 40′ has a pair of posts 42′ that are insertable into sleeves 16′ that are themselves affixed such as by welding to the front wall of the base 12′. Holes 62 at least through one of the sleeves 16′ and its associated post 42′ are so aligned to permit a padlock 64 to lock the anti-tilt railing to the base during use after the anti-tilt railing has been placed into position.

third embodiment

[0029]In FIG. 11, panel stack safety holder 110 is seen to be an integral, one-piece construction having a base plate 112 that is horizontal and presenting a horizontal top surface 114. Mounting plate 130 is an upstanding wall section at an angle β with base plate 112 and is adapted to be affixed to an adjacent wall structure (see FIG. 5). Anti-tilt section 140 is also an upstanding plate, at an angle γ with base plate 112. Angle β is preferably 90° while angle γ is preferably about 80°. Gusset plate 122 is joined to mounting plate 130 and joins base plate 112 about at least six inches from mounting plate 130 (and thus the adjacent wall structure), assuring that a panel stack (see FIG. 5) is tilted at a relatively safe angle to lean against the adjacent wall structure, while anti-tilt section 140 assures against toppling of the panel stack.

[0030]The panel stack safety holder of the present invention can also be mobile, as seen in FIG. 12. Holder 210 is provided with a set of swivela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com