Sportswear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

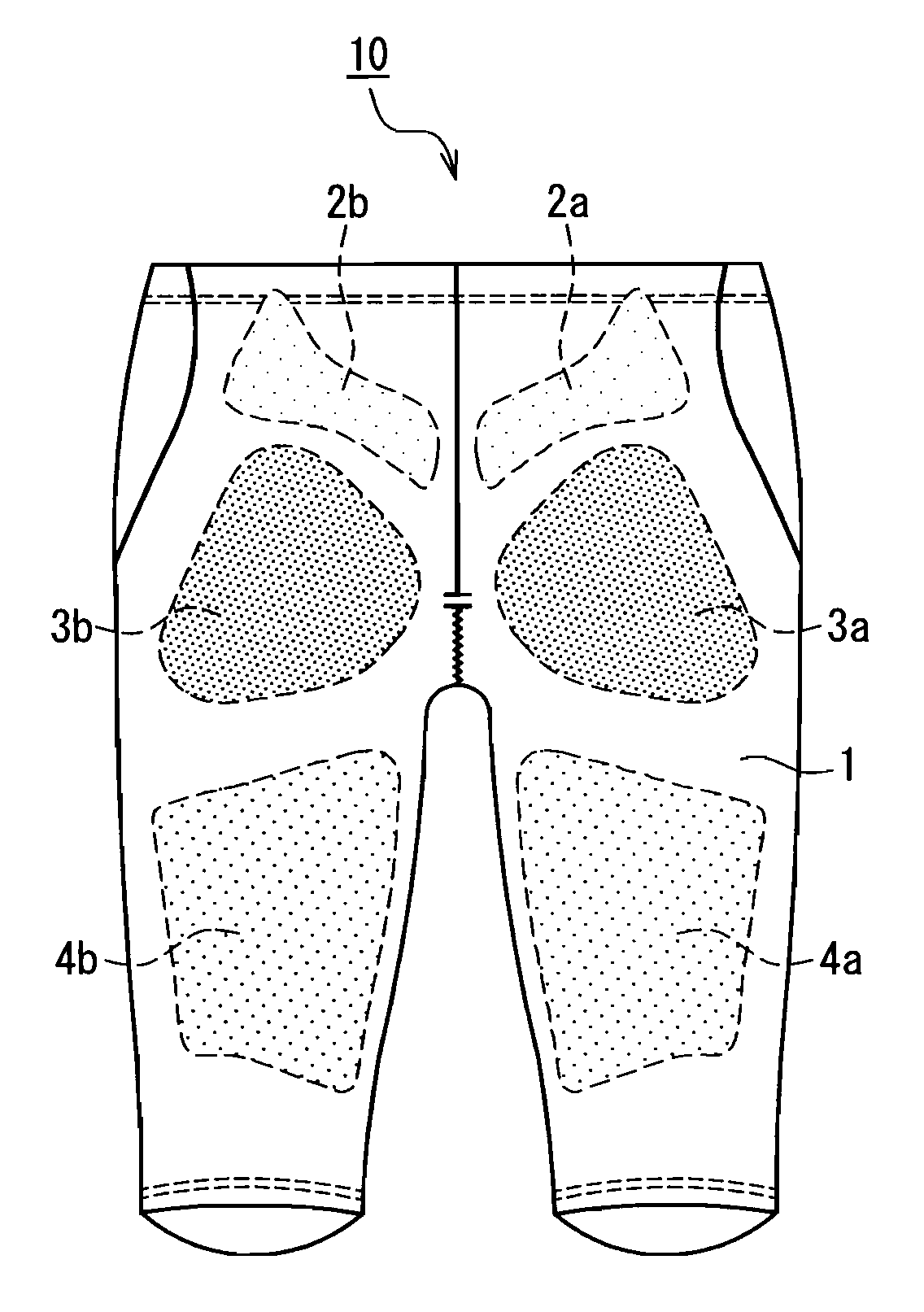

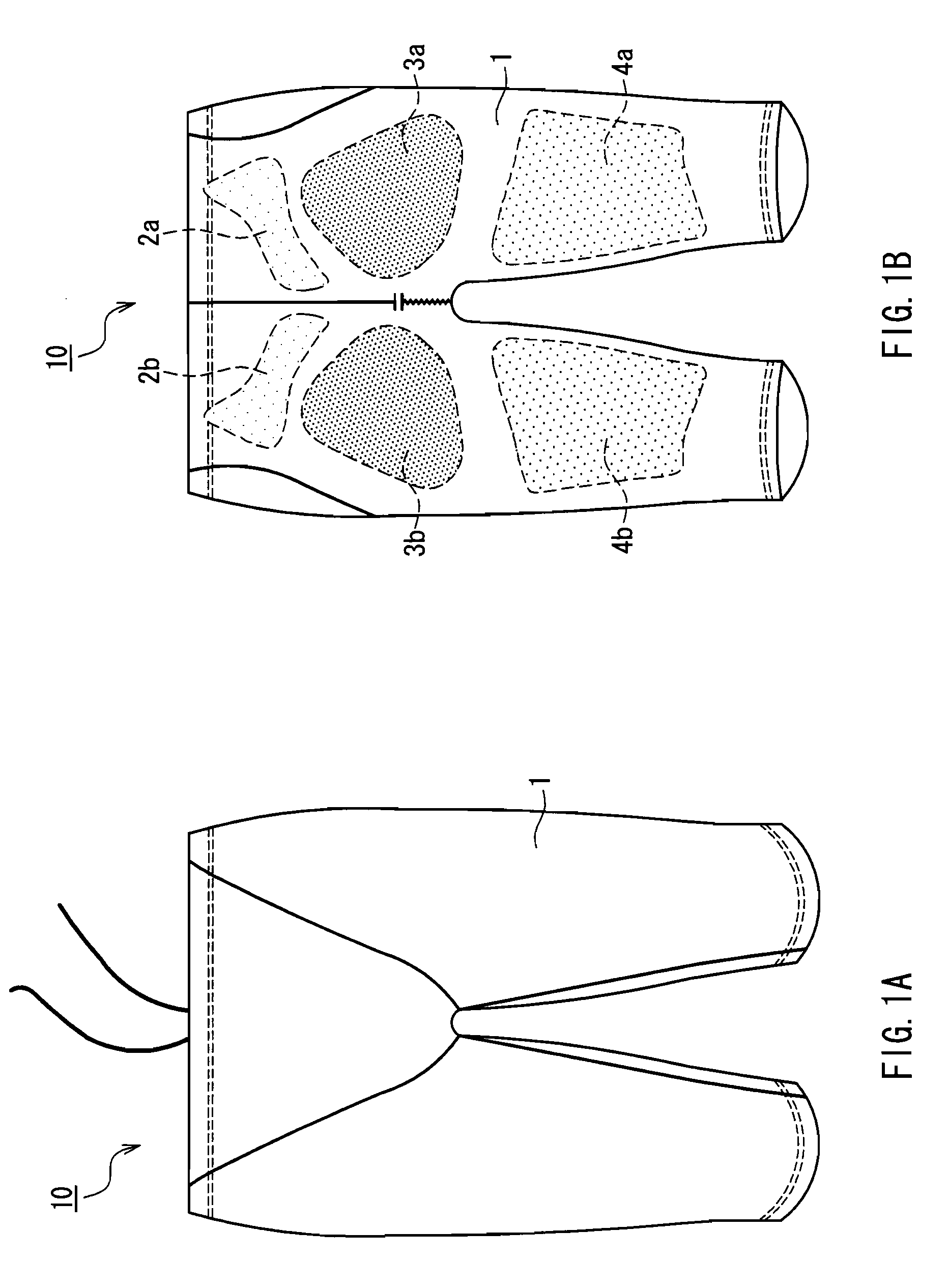

[0067]As shown in FIGS. 1A and 1B, a region A (2a, 2b) that covers at least the back of the waist, a region B (3a, 3b) that includes the rounded portions of the hips, and a region C (4a, 4b) that includes the back of the thighs were separately arranged on the surface of a stretch base fabric 1 by providing a non-stretch or low-stretch sheet by attaching a transfer sheet by thermal pressing so as to reinforce tension in the direction of extension of the hip joints.

[0068]As the stretch base fabric, a fabric woven in a plain weave with a weight per unit area of 110 g / m2 was used. For the warp yarn, a yarn made by covering 44 dtex (decitex) polyurethane (Pu) filaments with 33 dtex (decitex) nylon filaments with a filament number of ten was used, and for the weft yarn, a yarn made by covering 44 dtex (decitex) polyurethane (Pu) filaments with 33 dtex (decitex) nylon filaments with a filament number often was used. The number of warp yarns per inch was 161, and the number of weft yarns pe...

example 2

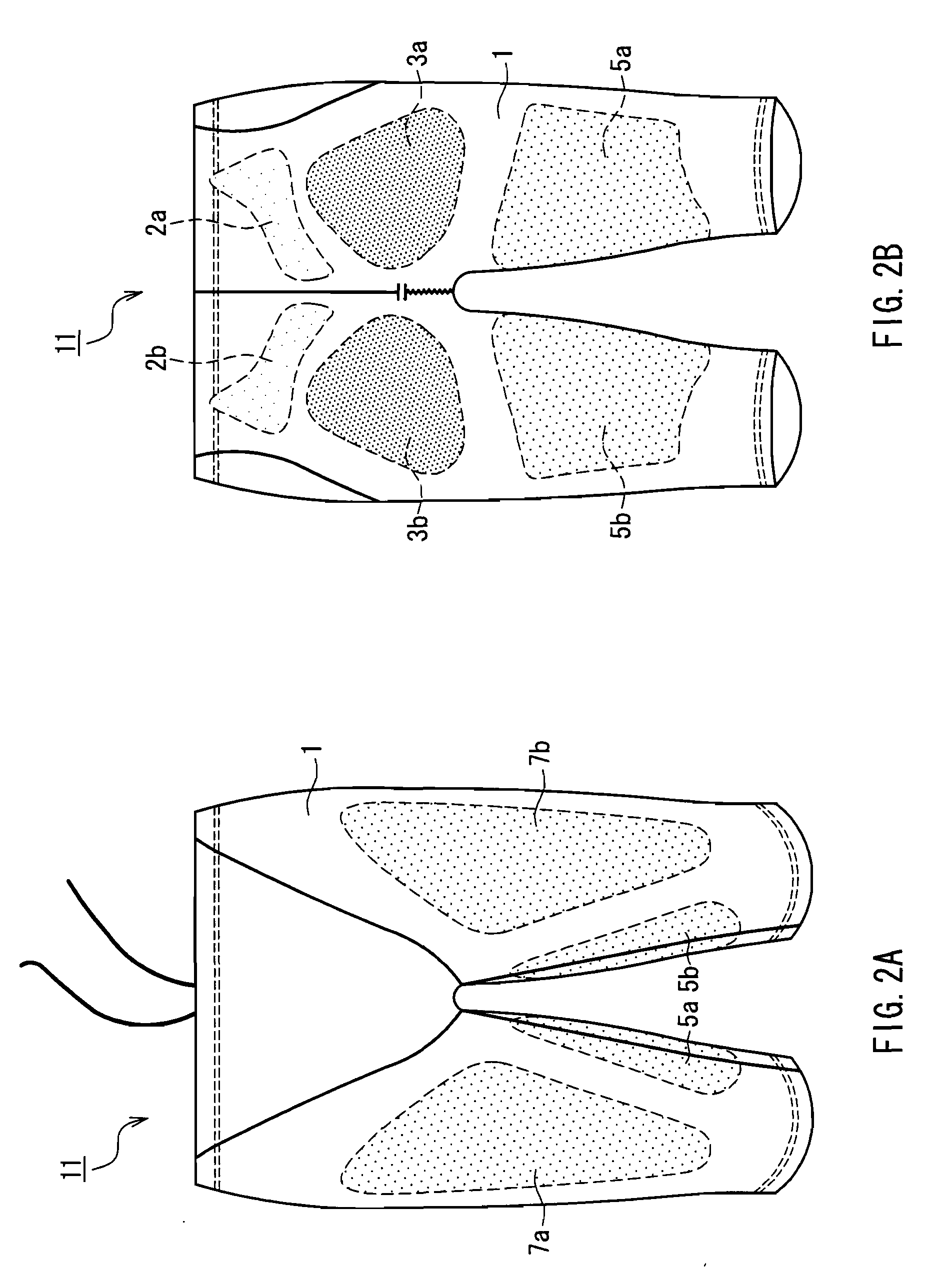

[0071]A pair of half leggings was produced in the same manner as in Example 1 except that the half leggings were configured as shown in FIGS. 2A and 2B.

[0072]Five male competitive swimmers were instructed to wear the half leggings of Comparative Example 1 and Examples 1 and 2, and to respond to the items shown in Tables 1 to 3. Each item was rated on a scale of 1 to 5, with 5 being strongly agreed, 4 being mostly agreed, 3 being somewhat agreed, 2 being somewhat disagreed, and 1 being disagreed.

TABLE 1SubjectSubjectSubjectSubjectSubjectComparative Example 1ABCDEWhen worn: the buttocks are pressed down21212When worn: the legs are pulled backward22111During swimming: the lower body can float21121During swimming: the legs can be moved easily54454Total118898Average2.75222.252

TABLE 2SubjectSubjectSubjectSubjectSubjectExample 1ABCDEWhen worn: the buttocks are pressed down45434When worn: the legs are pulled backward54334During swimming: the lower body can float54445During swimming: the leg...

example 3

[0076]A one-piece type swimsuit was produced in the same manner as in Example 1 except that the swimsuit was configured as shown in FIGS. 9A and 9B. As in Examples 1 to 2, five female competitive swimmers were instructed to wear the swimsuit and to respond to the items shown in Table 5. Each item was rated on a scale of 1 to 5, with 5 being strongly agreed, 4 being mostly agreed, 3 being somewhat agreed, 2 being somewhat disagreed, and 1 being disagreed.

TABLE 5SubjectSubjectSubjectSubjectSubjectExample 3FGHIJWhen worn: the buttocks are pressed down45444When worn: the legs are pulled backward45554During swimming: the lower body can float45555During swimming: the legs can be moved easily53545Total1718191818Average4.254.54.754.54.5

[0077]As can be seen dearly from the results of Tables 4 and 5, in Comparative Example 2, all subjects gave low ratings to all items except for the item “During swimming: the legs can be moved easily”, with the average score of 2 to 2.75. On the other hand, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com