Off-season start-ups to improve reliability of refrigerant system

a technology of refrigerant system and off-season start-up, which is applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of no longer present compressor damage, exacerbate the problem of potential compressor damage or its performance degradation, and achieve the effect of avoiding severe flood startups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

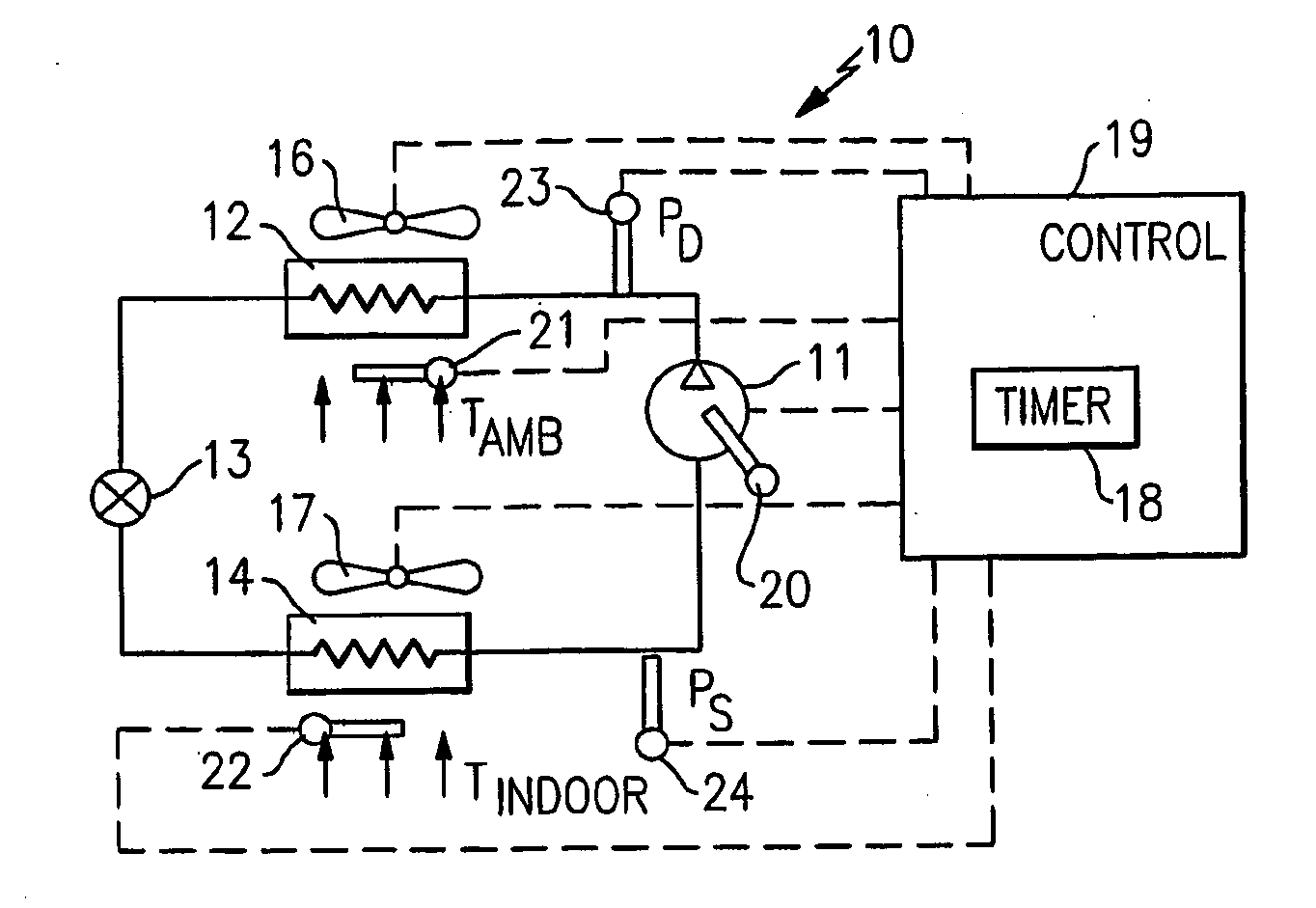

[0011]A basic vapor compression system 10 normally includes a compressor 11, a condenser 12, an expansion device 13 and an evaporator 14 interconnected in serial refrigerant flow communication.

[0012]A refrigerant vapor from the evaporator 14 is delivered to the compressor 11 where it is compressed, and the compressed vapor then flows to the condenser 12 where it is desuperheated, condensed and typically subcooled by a secondary fluid such as ambient air. Then the liquid refrigerant passes to the expansion device 13 where it is expanded to a lower pressure and temperature to form a two-phase (liquid and vapor) mixture with a portion of the refrigerant being flashed to a vapor. A vapor and liquid refrigerant mixture than passes to the evaporator 14 where it is evaporated and typically superheated by another secondary fluid such as air to be delivered to a conditioned space, while cooling this secondary fluid. The refrigerant vapor then passes to the compressor 11 to complete the cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com