Monopole acoustic transmitter ring comprising piezoelectric material

a technology of piezoelectric material and acoustic transmitter, which is applied in the direction of instruments, measurement devices, seismology, etc., can solve the problems of further limiting space, restricting the measurement range, and the relationship between the ring diameter and the frequency so as to improve the tool mode signal and reduce the effect of the effect of the output acoustic pressure puls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

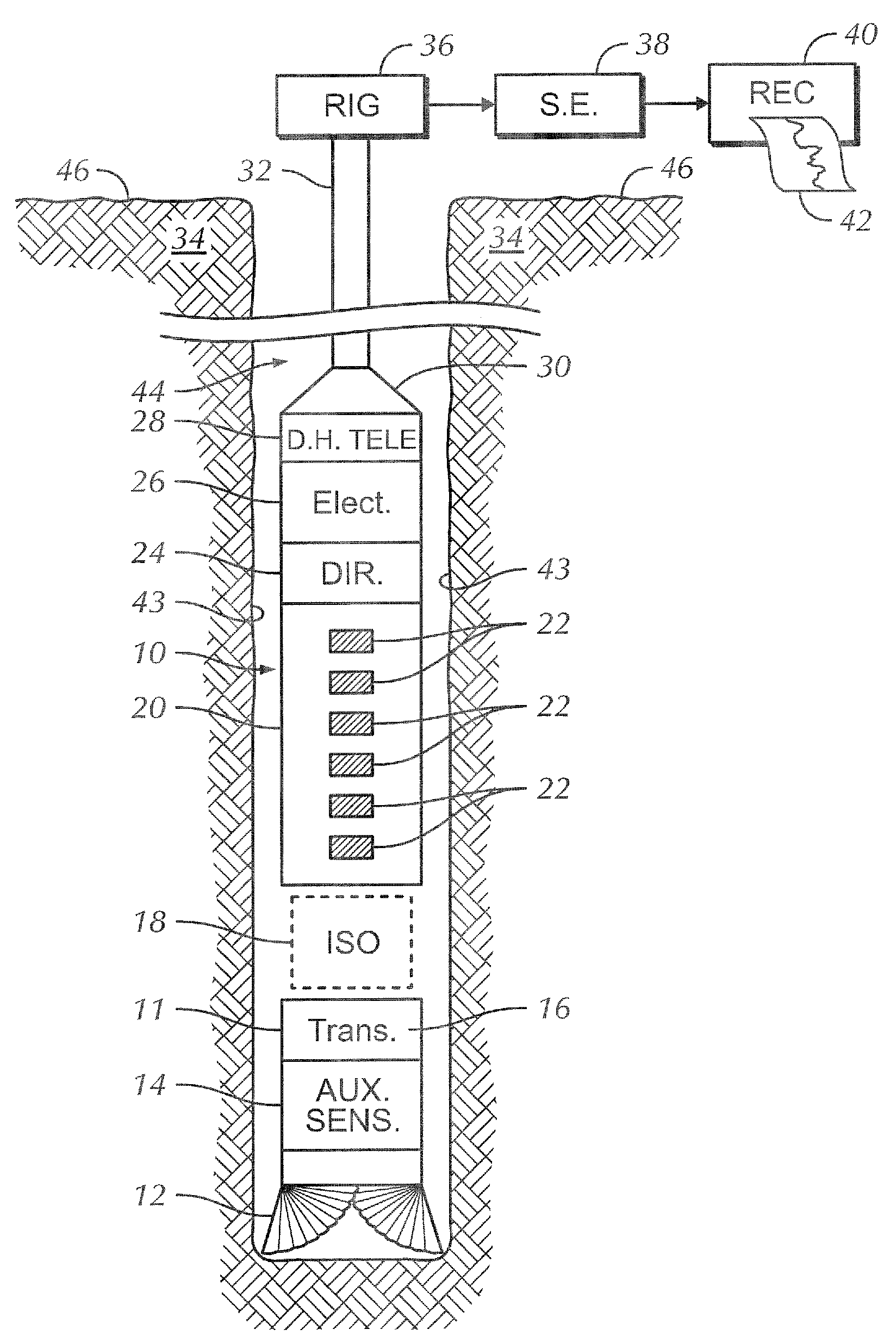

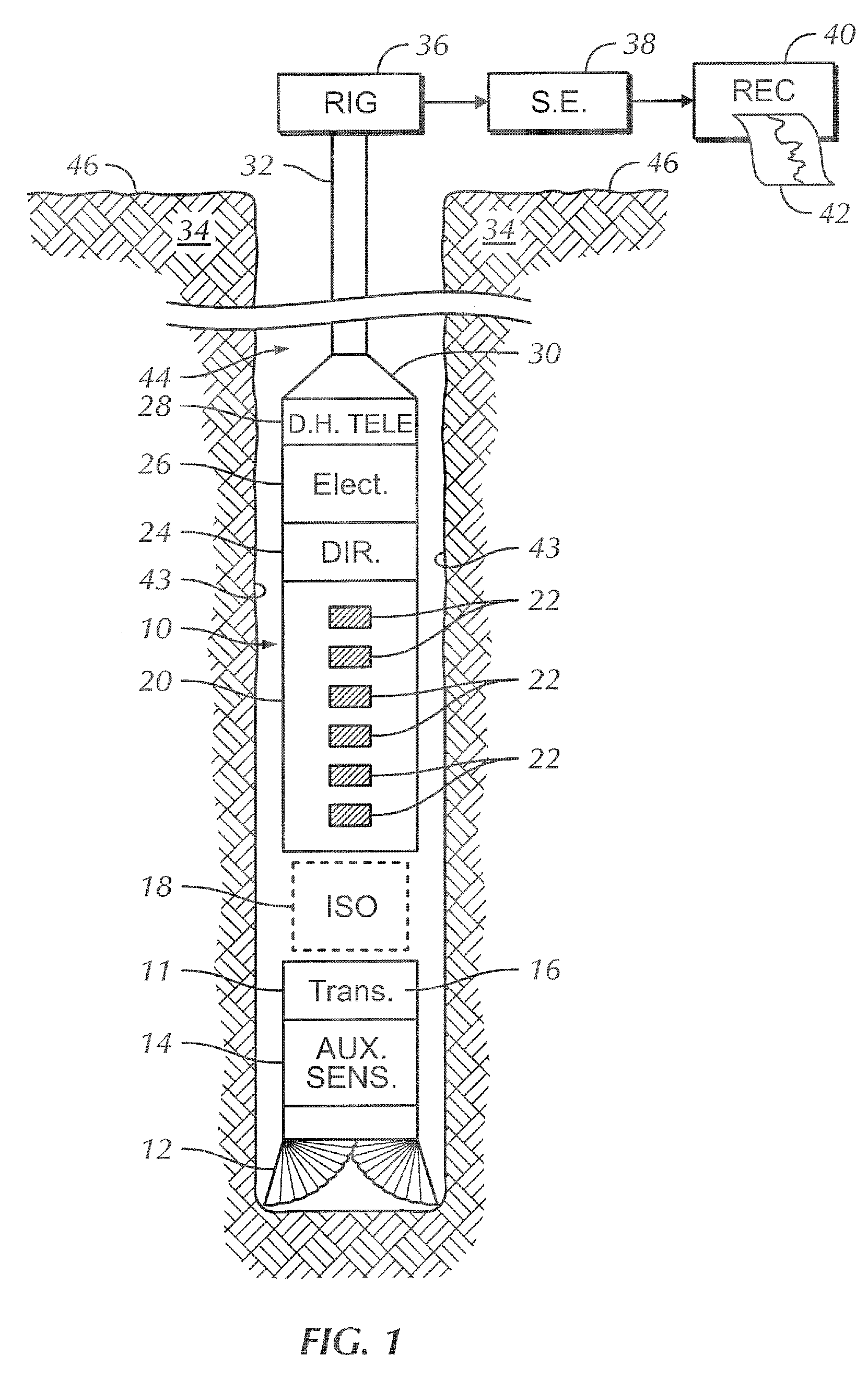

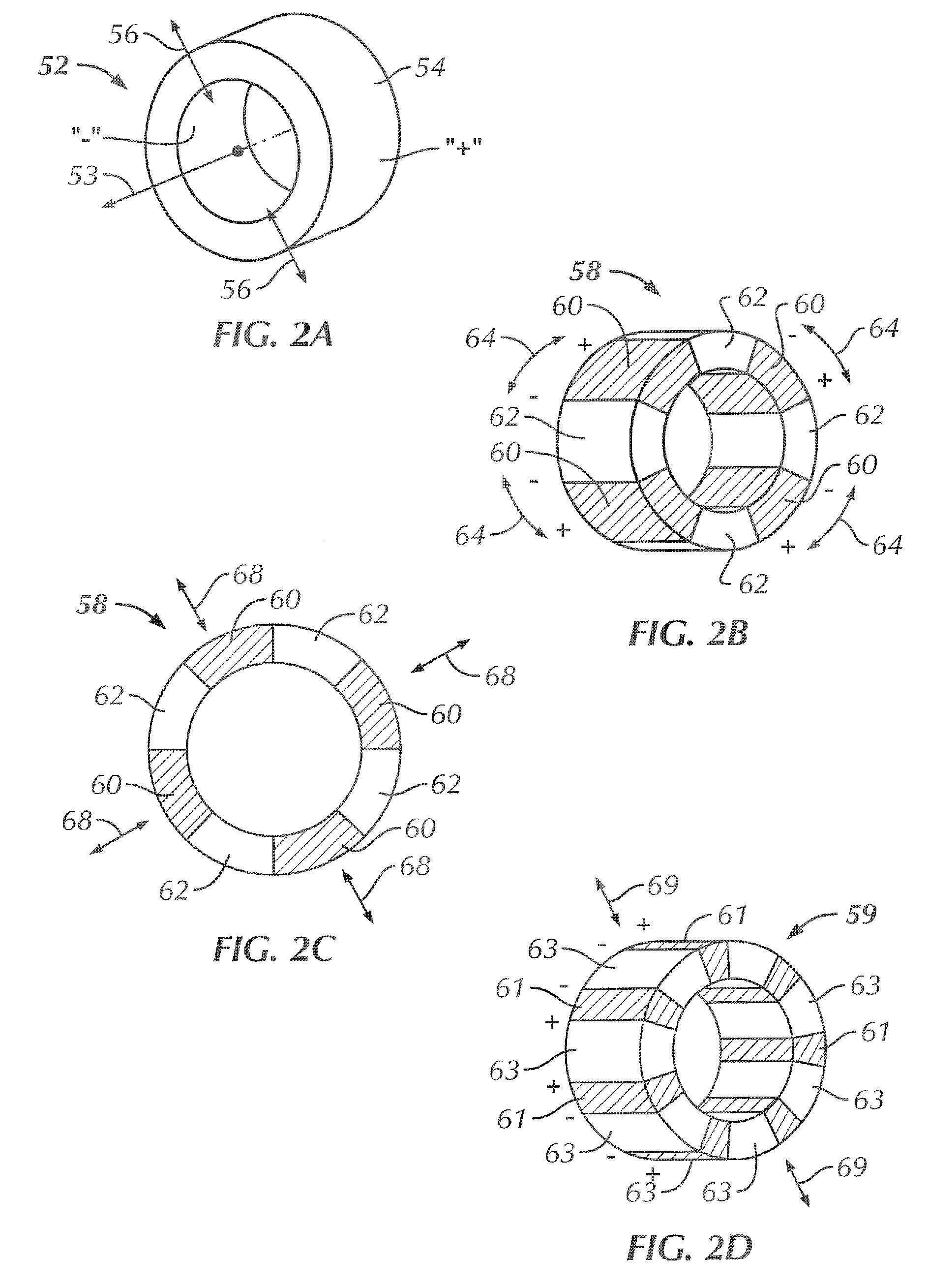

[0039]the transmitter ring 52 is illustrated in perspective in FIG. 2a and comprises a single loop of piezoelectric material 54. This embodiment of the transmitter ring will be referred to as a “continuous” ring embodiment. The polarization of the ring is indicated by “+” and “−”. Electrical connections to the piezoelectric material 54 (see FIG. 3) are such that the ring 52 expands or contracts upon application of a voltage. As an example, a positive voltage applied the outer and inner surfaces of the ring 52 expands the ring outward in the radial direction, while a negative voltage contracts the ring in the axial direction. This expansion and contraction is illustrated conceptually by the arrows 56. The normal of the transmitter ring, in this and other disclosed embodiments, is illustrated by the arrow 53.

second embodiment

[0040]the transmitter ring 58 is illustrated in perspective in FIG. 2b, and comprises a plurality of arc segments 60 of piezoelectric material with intervening arc segments 62 of material. This embodiment will be referred to as a “segmented” ring. For a given ring dimension, intervening arc segments 62 of relatively light material, such as alumina, increase output frequency. Conversely, intervening arc segments of relatively heavy materials, such as tungsten, decrease output frequency. The polarization of each segment 60 of each piezoelectric segment is again indicated by “+” and “−”. Electrical connections are such that the same voltage is applied simultaneously to each piezoelectric segment 60. Each segment 60 expands and contracts simultaneously in an azimuthal direction illustrated conceptually by the arrows 64.

embodiment 58

[0041]FIG. 2c is a cross sectional view of the segmented ring embodiment 58. Since all segments are rigidly bound to one another, the azimuthal expansions and contractions (see arrows 64) of the piezoelectric segments 60 result in a radial expansion and contraction of the segmented ring 58. The ring expansion and contraction is illustrated conceptually by the arrows 68.

[0042]FIG. 2d illustrates the “striped” ring embodiment 59. The embodiment comprises continuous ring piezoelectric ring 63 on which active arc segments are polarized or polled. This is accomplished by applying, to the surfaces of the ring 63, bands 61 or “stripes” of electrode material 61 thereby defining active arc segments. The active arc segments of piezoelectric material are polarized by the bands of electrode material 61 as indicated by “+” and “−” annotations. The entire striped ring 59 is activated simultaneously, as opposed to the segmented ring embodiment 58 in which certain segments of piezoelectric material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com