Alloy nanoparticles of sn-cu-ag, preparation method thereof and ink or paste using the alloy nanoparticles

a technology of alloy nanoparticles and nanoparticles, which is applied in the direction of manufacturing tools, soldering devices, and capacitors, can solve the problems of significant growth in the development of lead-free solder materials, and the difficulty of providing nanoparticles with a size of less than 50 nm, and achieves good electrical conductivity and low calcinating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

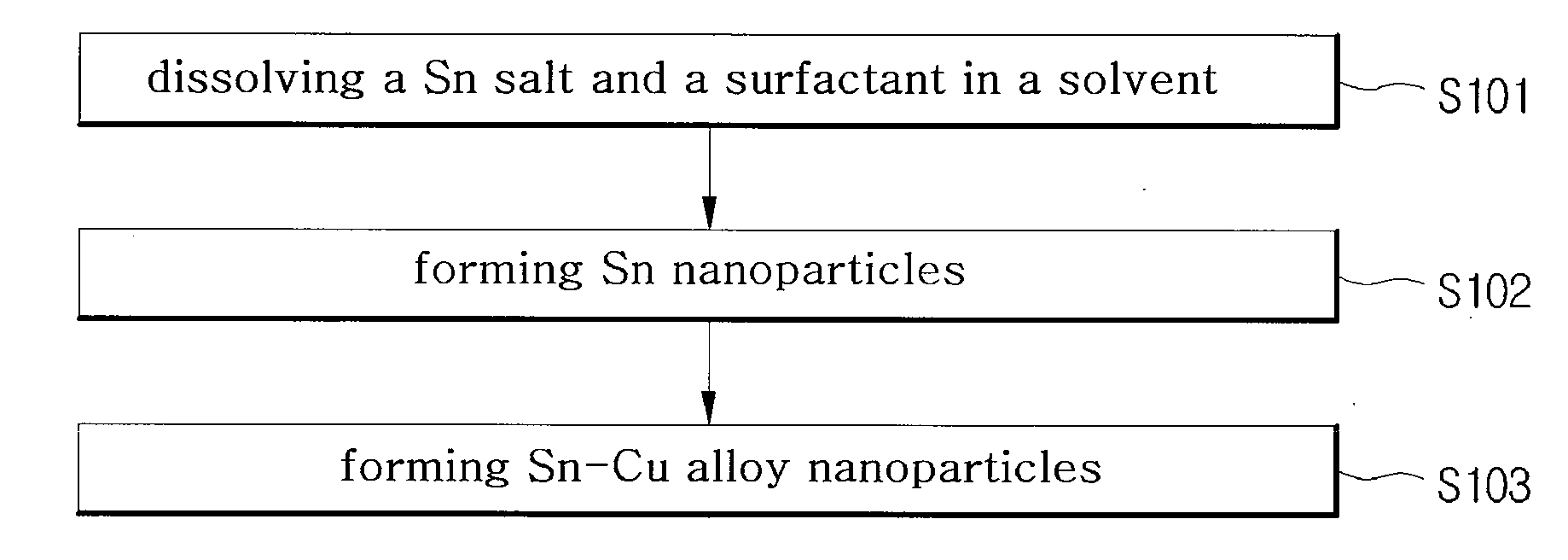

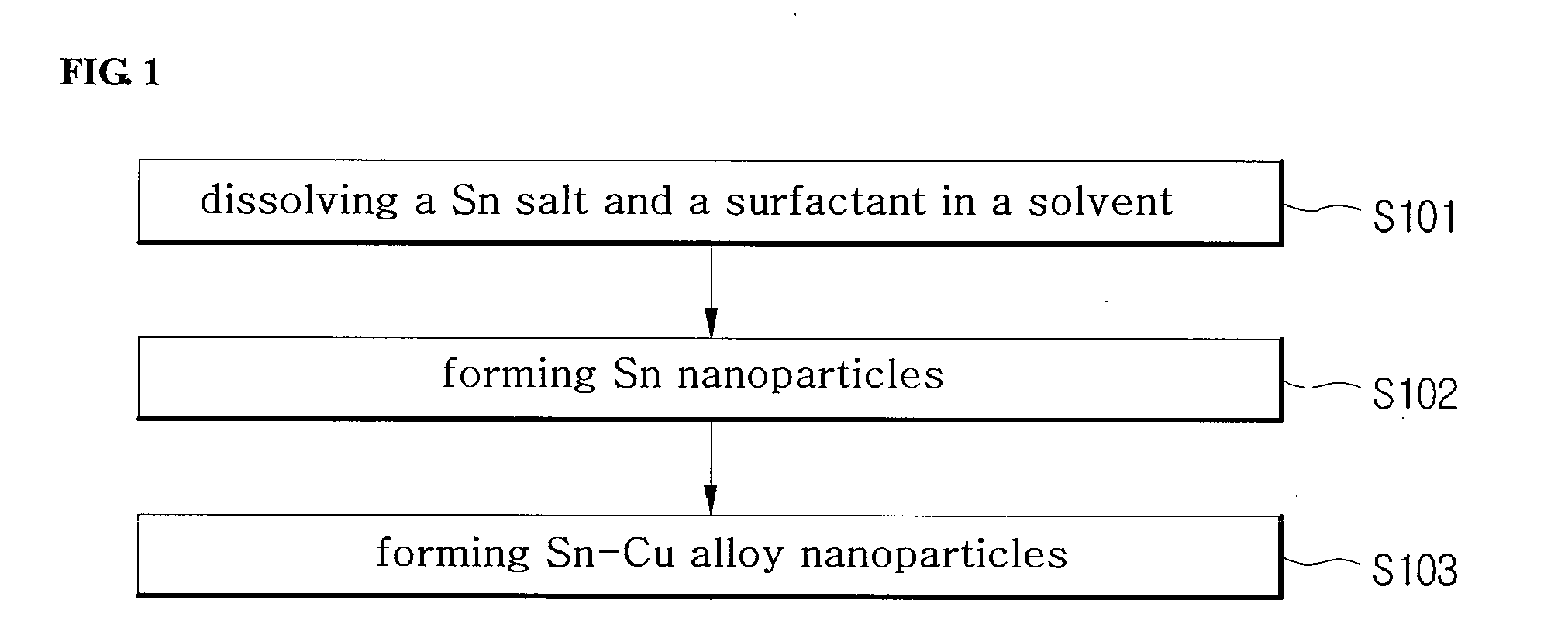

Preparation of Alloy Nanoparticles having Sn:Cu=99.3 wt %:0.7 wt %

[0053]0.135 g of Sn(CH3COO) and 24 equivalents of polyvinyl pyrrolidone(PVP) were added into 1,5-pentanediol(1,5-PD) and dissolved by slowly heating to 200° C. under N2. When the solution was turned into a clear solution, a small amount of NaBH4 sonicated in 1,5-pentanediol was added. As soon as NaBH4 was added, the solution was turned into dark brown color which indicated the formation of Sn particles. The reaction was further performed for 10 min at the same temperature and then 5 mL of Cu(CH3COCHCOCH3)2 sonicated in 1,5-pentanediol was added into the reaction solution. The reaction solution was further reacted for 10 min to provide dispersion including alloy nanoparticles having 99.3 wt % Sn-0.7 wt % Cu. Ethanol was added to the dispersion and the mixture was then performed for the centrifugation (8000 rpm, 20 min) 3 times to remove excess amount of remaing surfactant and other organic materials to finally provide ...

example 2

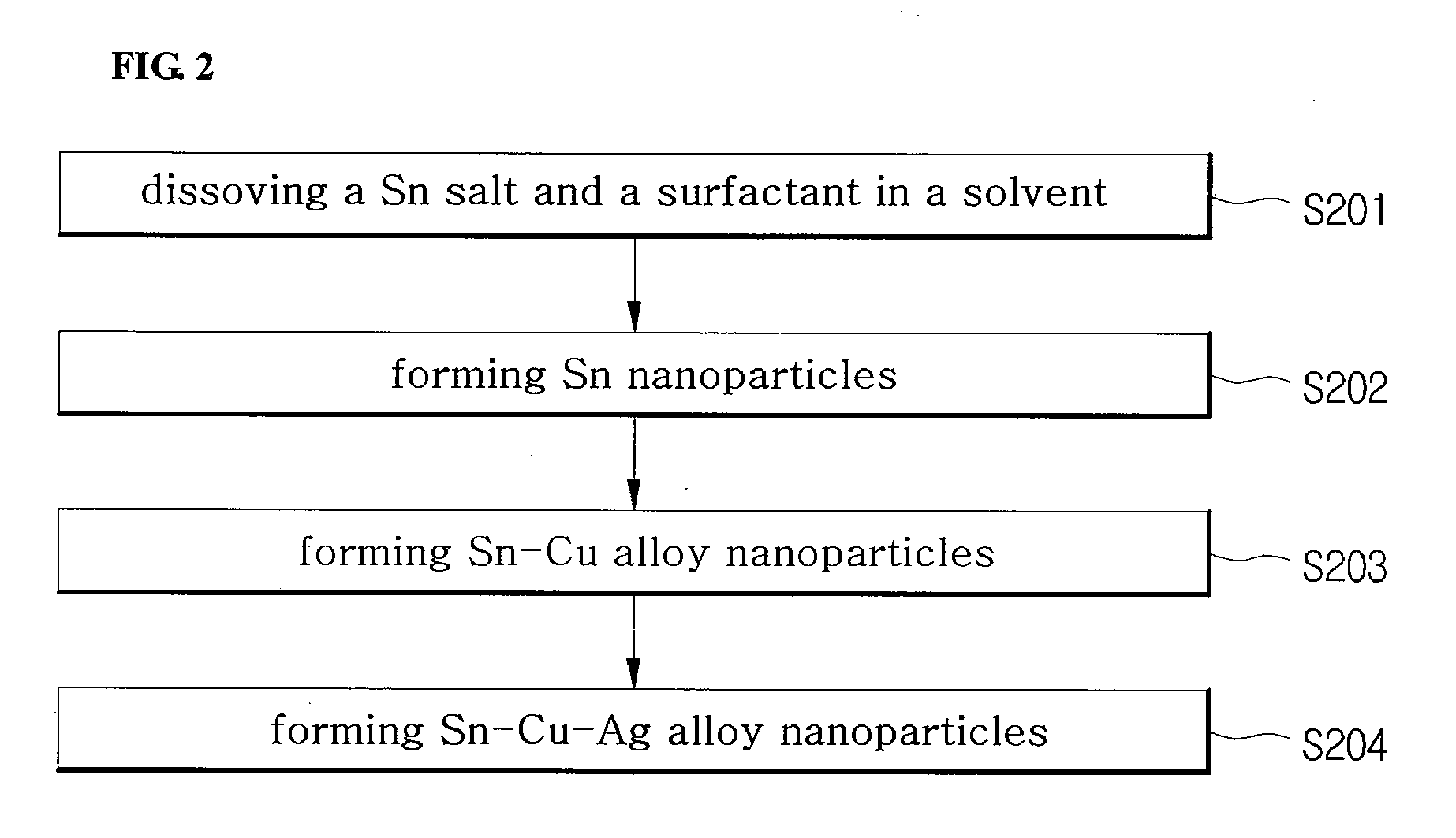

Preparation of Sn:Cu:Ag=96.5 wt %:0.5 wt %:3.0 wt % Alloy Nanoparticles

[0056]Sn(CH3COO) 1.35 g and 24 equivalents of polyvinyl pyrrolidone (PVP) were added into 1,5-pentanediol(1,5-PD) and dissolved by slowly heating to 200° C. under N2. When the solution was turned into a clear solution, a small amount of NaBH4 sonicated in 1,5-pentanediol was added. As soon as NaBH4 was added, the solution was turned into dark brown color which indicated the formation of Sn particles. The reaction was further performed for 10 min at the same temperature and then a small amount of Cu(CH3COCHCOCH3)2 sonicated in 1,5-pentanediol was added into the reaction solution. The reaction solution was performed for another 10 min and then Ag(NO)3 sonicated in 1,5-pentanediol was added. The reaction solution was further reacted for 10 min to provide dispersion including alloy nanoparticles having 96.5 wt % Sn-3.0 wt % Ag-0.5 wt % Cu(weight ratio). Ethanol was added to the dispersion and the mixture was then per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com