Front Opening Unified Pod with latch component

a technology of latching and front opening, which is applied in the field of latching components disposed in the door of wafer containers, can solve the problems of wafer pollution and high failure rate, and achieve the effect of reducing failure rate and simplifying latching components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In order to disclose the skills applied in, the objectives of, and the effects achieved by the present invention in a more complete and clearer manner, preferred embodiments are herein described below in detail with related drawings disclosed for reference.

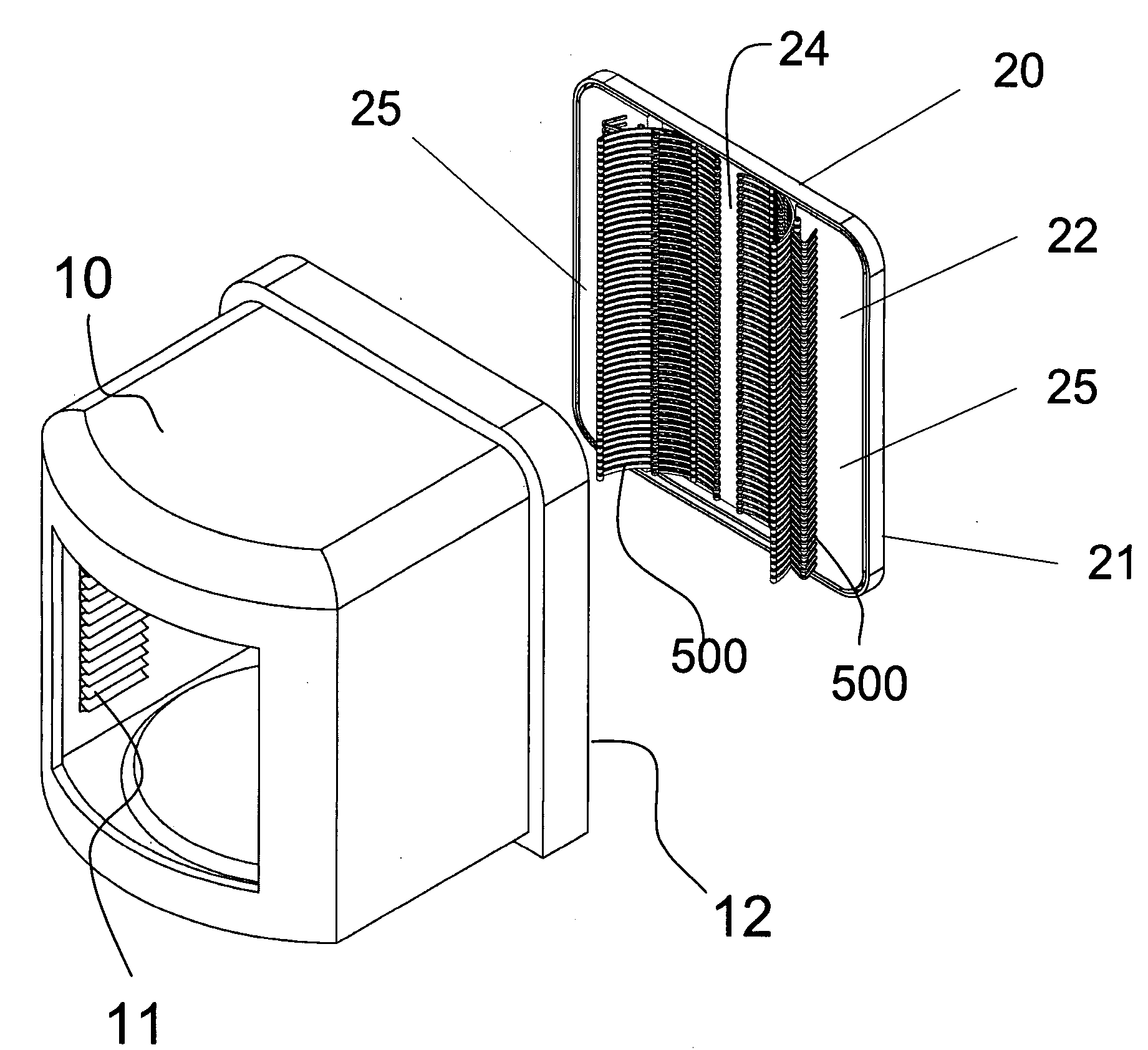

[0041]Referring to FIG. 5, which is a top view of latch component 60 in door 20 of front opening unified pod (FOUP) of the present invention. As shown in FIG. 5, the door 20 includes a pair of latch components 60, and each latch component 60 includes a cam 62 and a pair of moving bars 64 connected with two ends of cam 62. Wherein, the cam 62 is disposed with a pair of cam grooves 621 for being connected with corresponding moving bars 64, and each moving bar 64 includes a slide groove 642 for being fixed in by the roller 66 disposed between outer surface and inner surface of door 20.

[0042]Then referring to FIG. 6A, which is a magnified view of the ends of cam 62 that contact moving bars 64. As shown in FIG. 6, the moving bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com