System for configuring earth probes

a technology for earth probes and systems, applied in indirect heat exchangers, lighting and heating apparatuses, greenhouse gas reduction, etc., can solve the problems of considerable installation costs generated on the construction site of the probe, and achieve the effect of low assembly costs and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

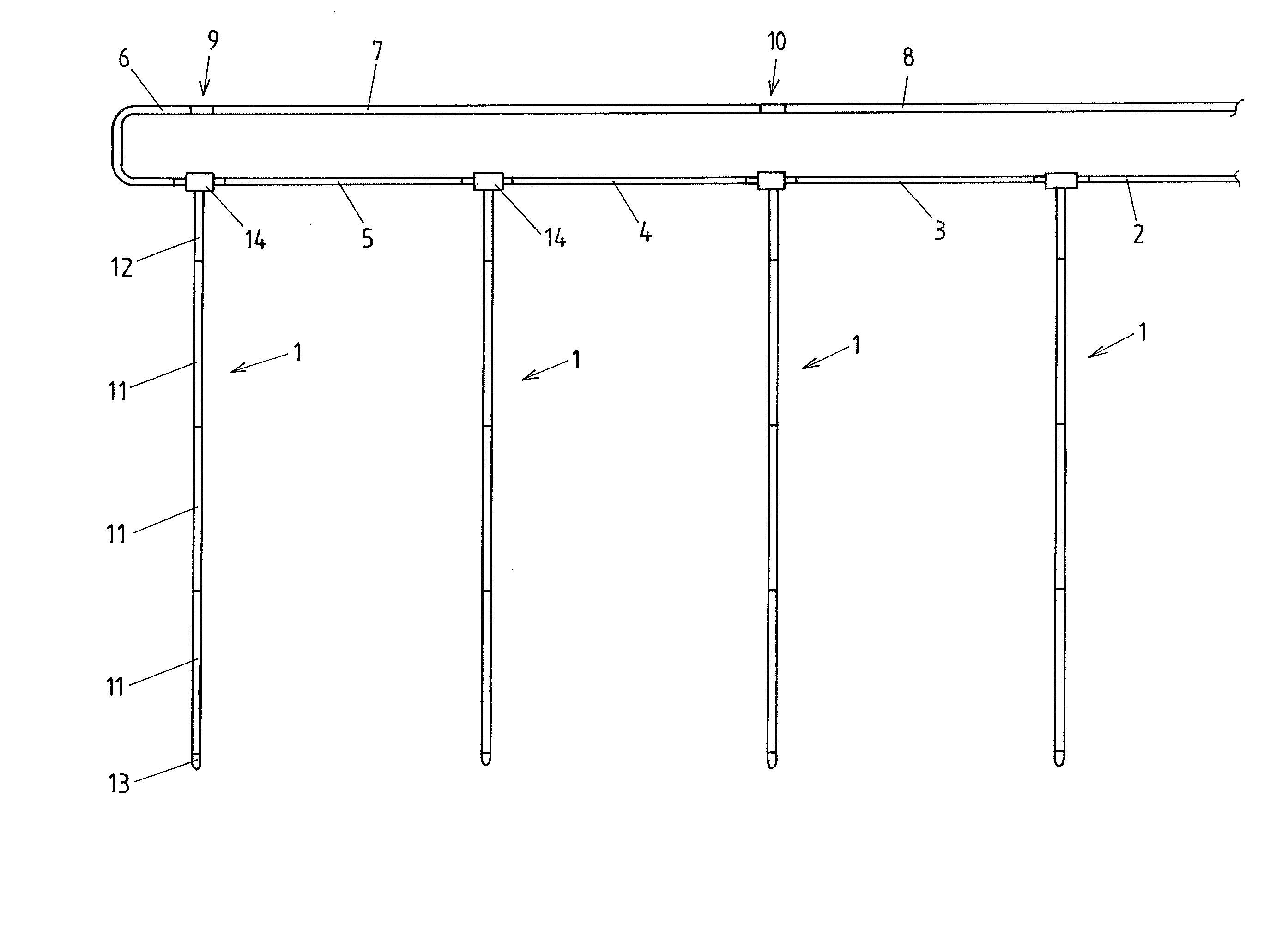

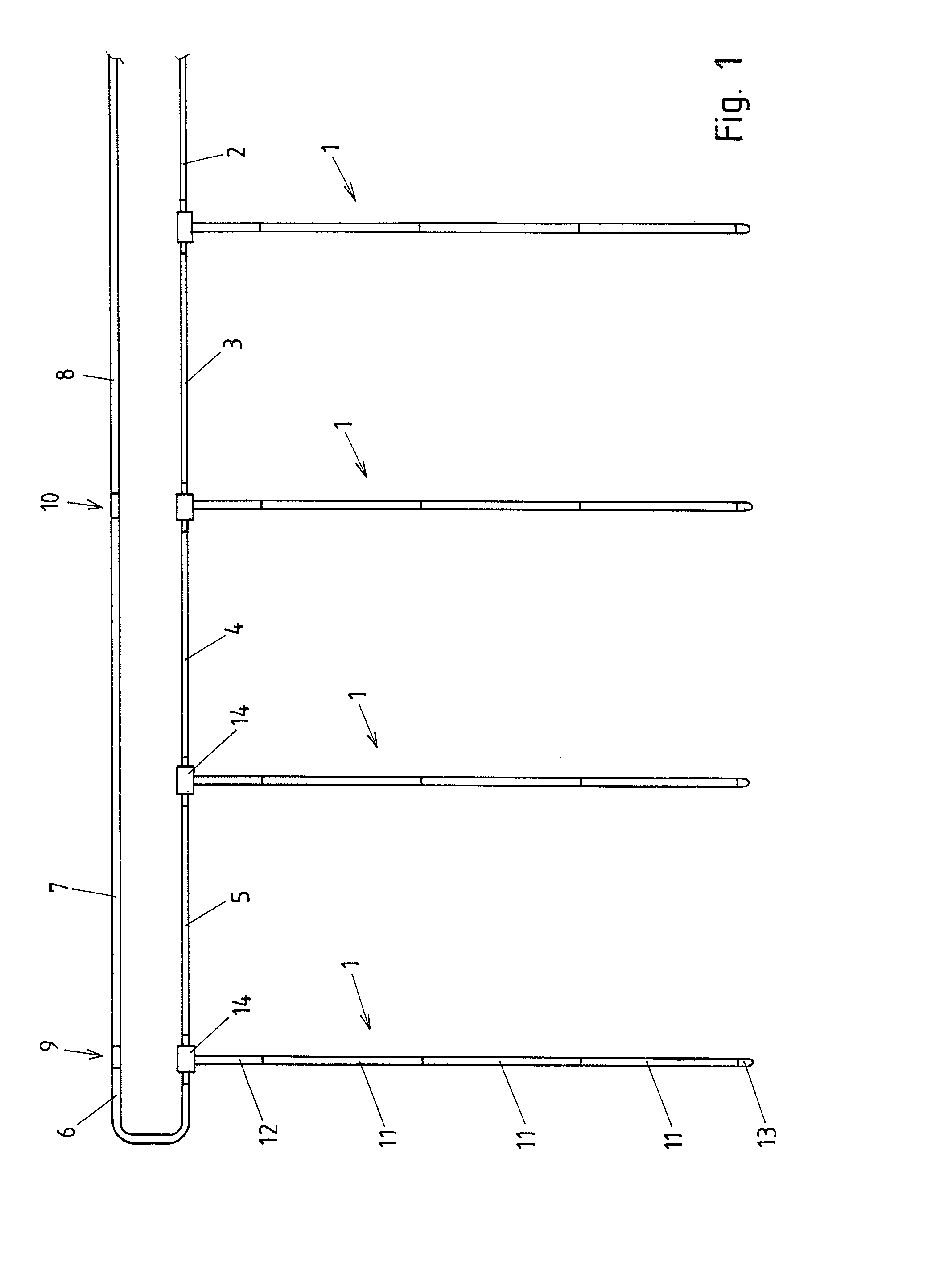

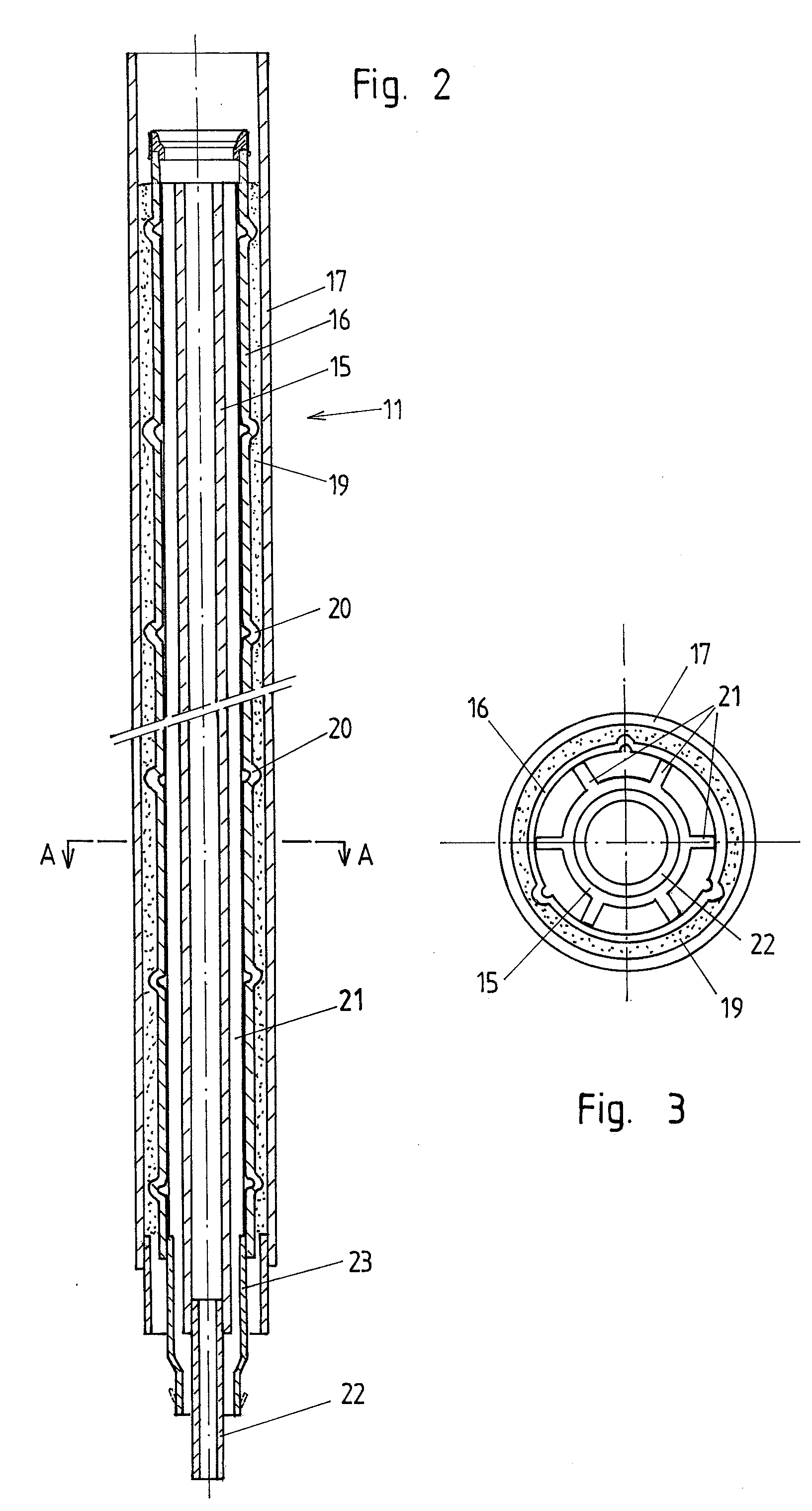

[0047]a system for forming geothermal probes will be explained below with reference to FIGS. 2 to 6. A probe module 11 of the system is shown in FIGS. 2 and 3. Advantageously, preassembled probe modules are provided in different standardized lengths, for example, in four different lengths.

[0048]Each probe module 11 forms a section of the longitudinal extent of the geothermal probe 1 and, in this way, a section of the line system of the geothermal probe 1 is formed by this probe module 11, wherein, in this embodiment, both a section 15 of the outgoing line transporting the heat-carrier medium from the top to the bottom and also a section 16 of the return line transporting the heat-carrier medium from the bottom to the top are formed. The sections 15, 16 are here formed by pipe pieces arranged coaxial to each other.

[0049]The probe module 11 has an outer pipe piece 17 that houses the section of the line system formed by the probe module 11. The intermediate space 18 between the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com