Pressure container with differential vacuum panels

a vacuum panel and pressure container technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of imposing significant and complex mechanical stress on the container structure, partial evacuation of the container, distortion of the container, etc., to improve the dent resistance and resistance to torsion displacement, and control the overall response to vacuum pressure. , the effect of improving the weight of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]A thin-walled container in accordance with the present invention is intended to be filled with a liquid at a temperature above room temperature. According to the invention, a container may be formed from a plastic material such as polyethylene terephthlate (PET) or polyester. Preferably, the container is blow molded. The container can be filled by automated, high speed, hot-fill equipment known in the art.

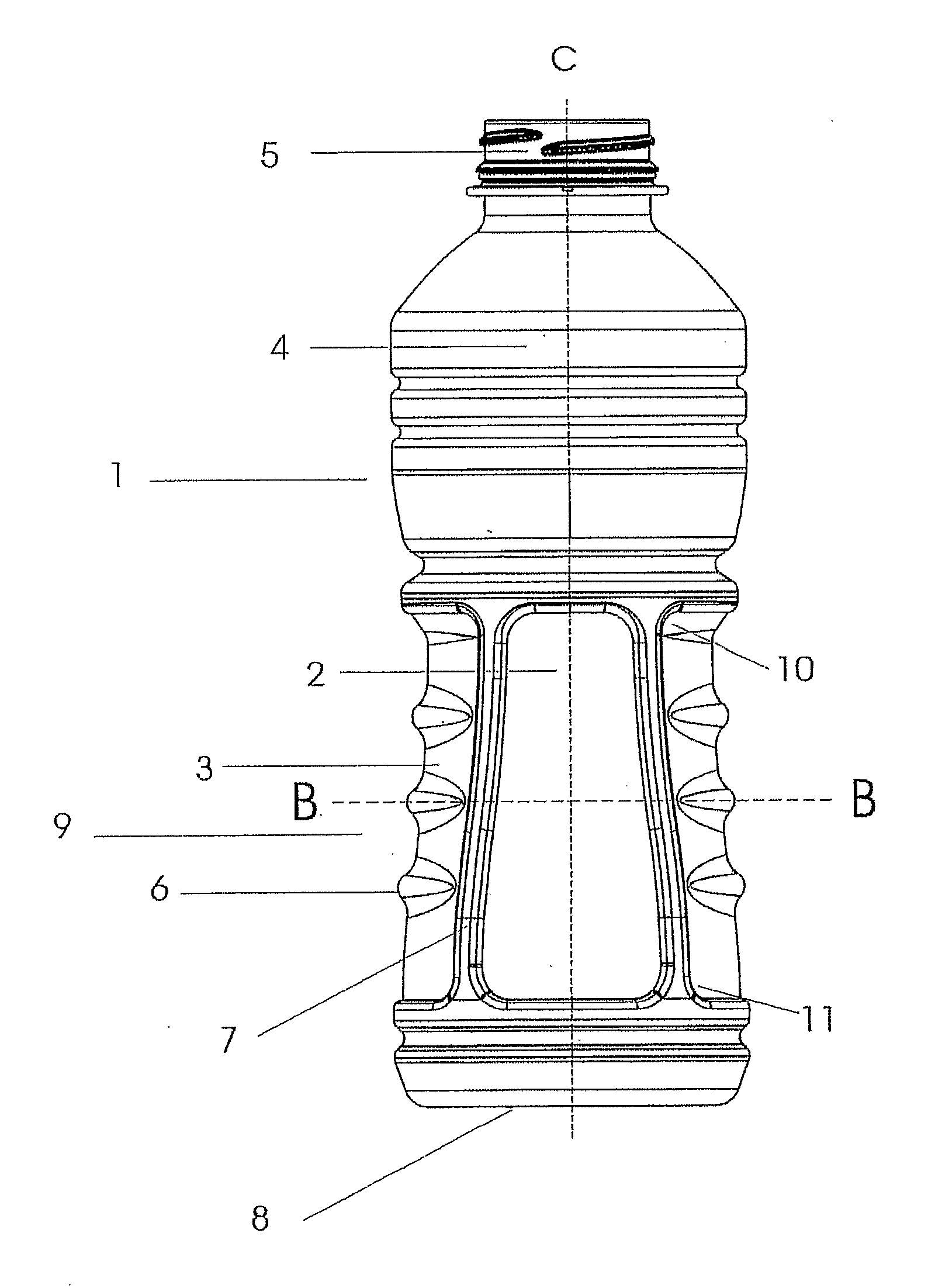

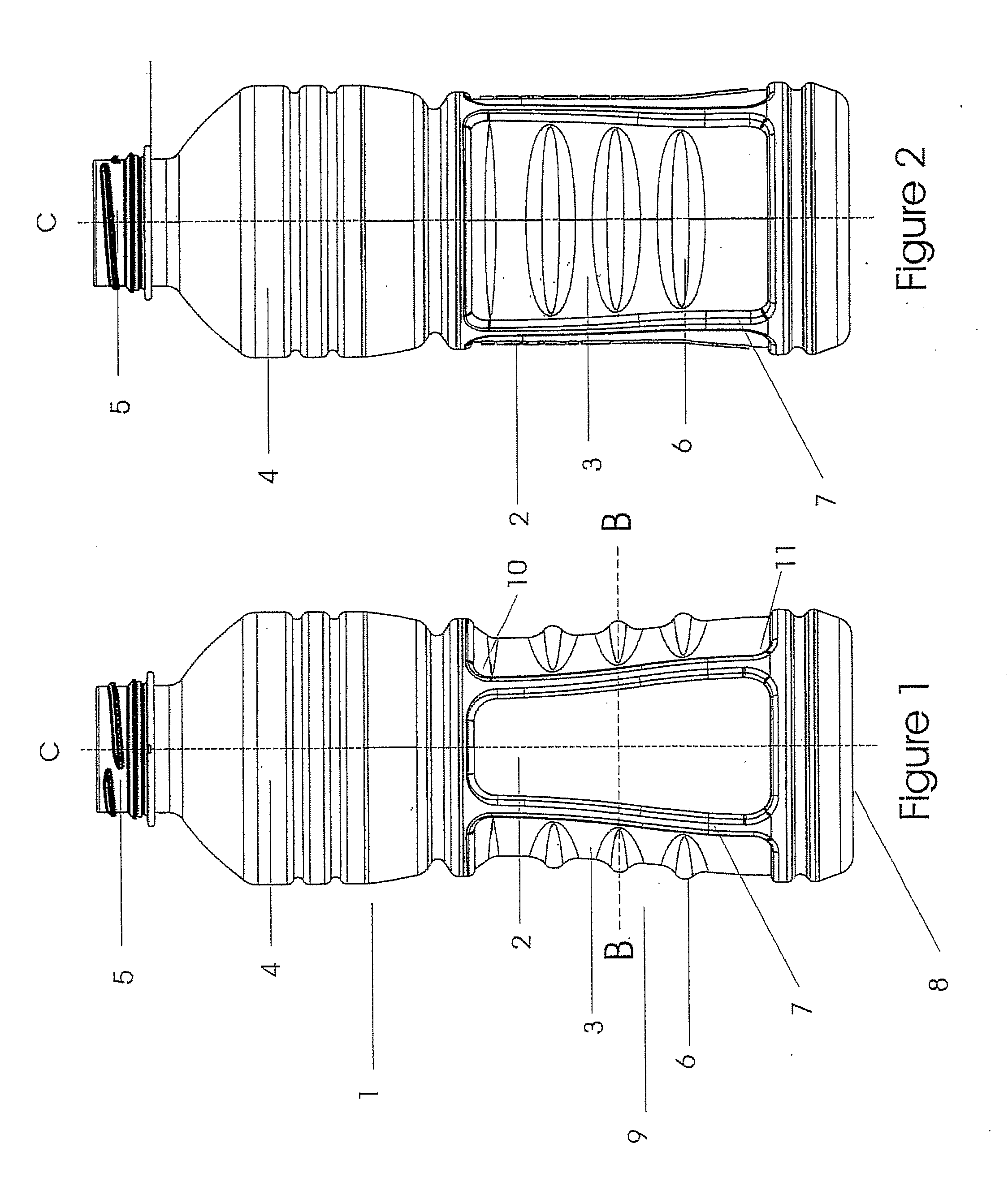

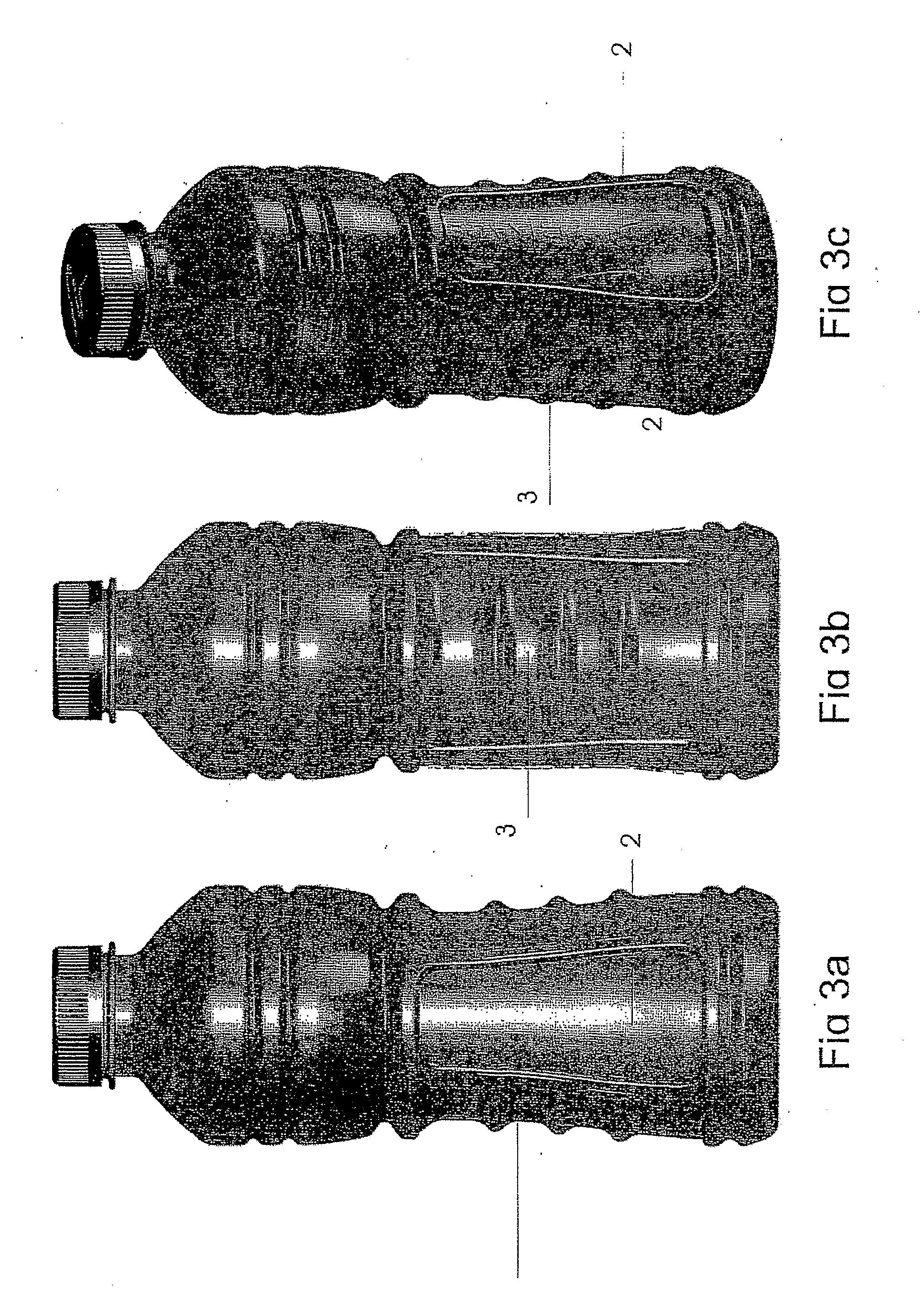

[0044]Referring now to the drawings, a preferred embodiment of the container of this invention is indicated generally in FIG. 1, as generally having many of the well known features of hot-fill bottles. The container (1), which is generally round or oval in shape, has a longitudinal axis (C) when the container is standing upright on its base. The container comprises a threaded neck (5) for filling and dispensing fluid. Neck (5) also is sealable with a cap (not shown). The preferred container further comprises a substantially circular base (8) and a bell (4) located below neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com