Hot galvanizing baking chilled steel with yield strength 180Mpa and producing method thereof

A yield strength, bake hardening technology, applied in hot dipping process, temperature control, coating and other directions, can solve the problems of excessive addition of trace alloying elements, low formability, complex addition, etc., and achieve significant economic and social benefits , good stamping performance, improve the effect of dent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

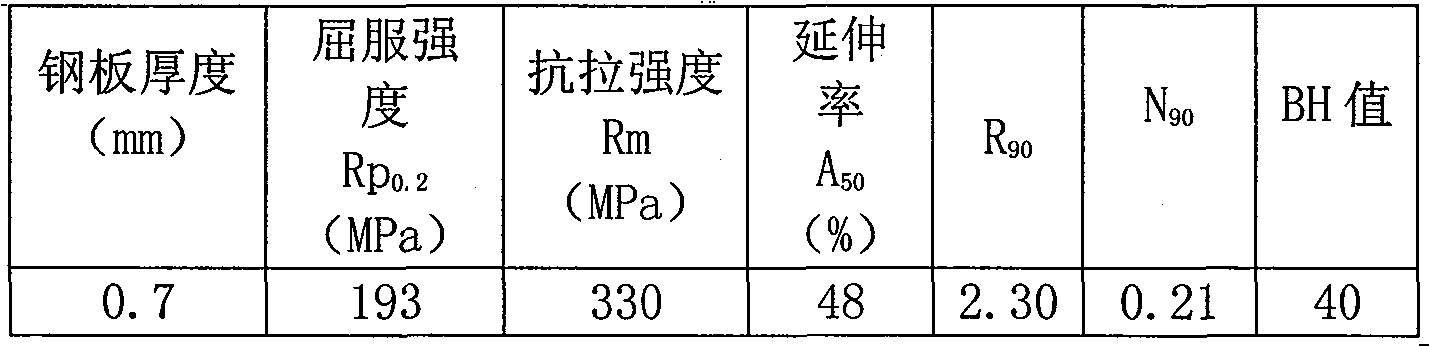

Embodiment 1

[0025] The test steel is the steel for the outer panels of the left and right rear doors of automobiles;

[0026] Yield strength 180Mpa hot-dip galvanized bake-hardening steel, its chemical composition and weight percentage are: C: 0.001, Si: 0.055, Mn: 0.40, P: 0.03, Nb: 0.005, Ti: 0.0031, ALs: 0.048, S< 0.015, N: 0.0010, the rest is Fe and unavoidable impurities.

[0027] The method for producing yield strength 180Mpa hot-dip galvanized baking hardening steel, its steps:

[0028] 1) Rough rolling: rough rolling at 1050°C;

[0029] 2) Finish rolling: the finish rolling temperature is controlled at 900°C;

[0030] 3) Coiling: coiling at 700°C;

[0031] 4) cold rolling: control the total reduction rate to carry out cold rolling under the condition of 65%;

[0032] 5) Continuous annealing: continuous annealing at 800°C;

[0033] 6) Cooling: Control the cooling rate at 50°C / s;

[0034] 7) Carry out finishing and set aside.

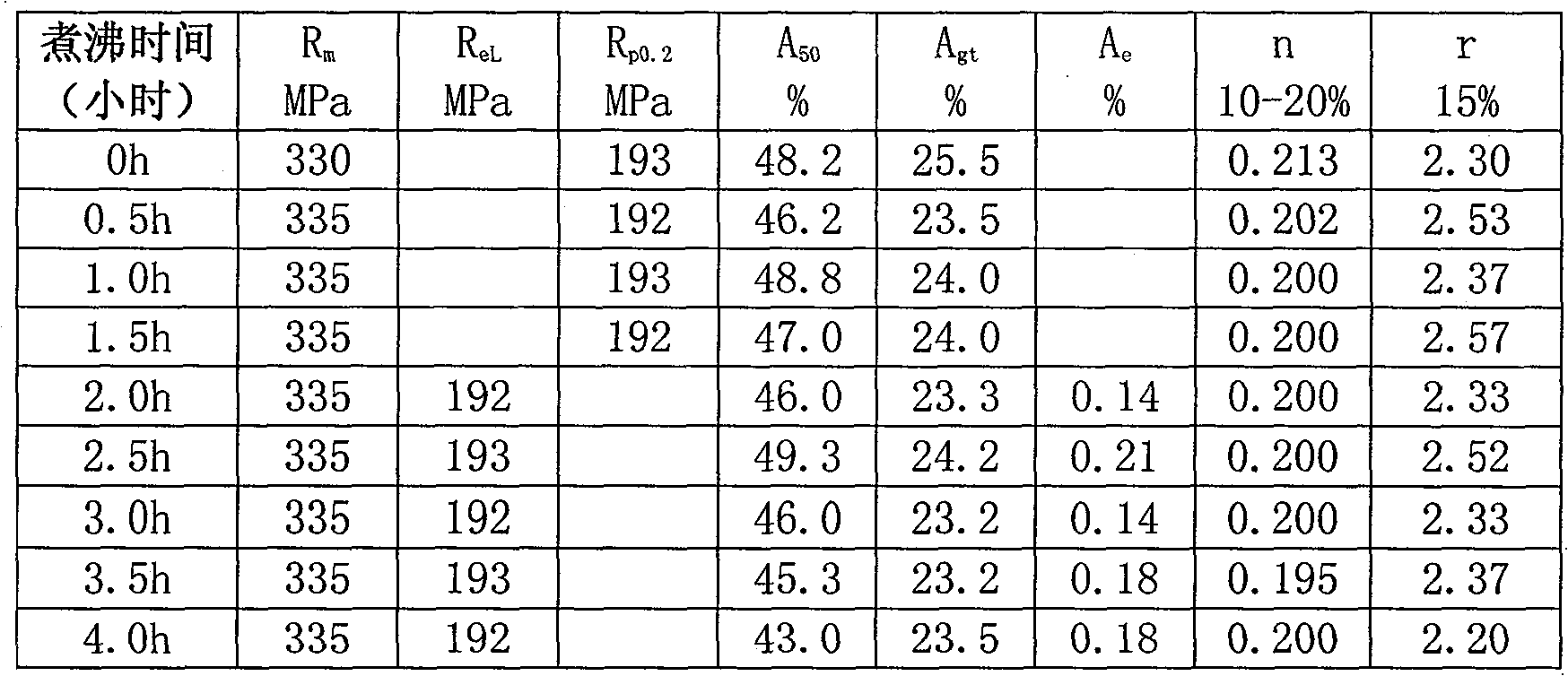

Embodiment 2

[0036] The test steel is the steel used for the outer panels of the left and right front fenders of the automobile;

[0037] Yield strength 180Mpa hot-dip galvanized bake-hardening steel, its chemical composition and weight percentage are: C: 0.0024, Si: 0.045, Mn: 0.33, P: 0.015, Nb: 0.011, Ti: 0.0035, ALs: 0.034, S< 0.015, N: 0.0024, and the rest are Fe and unavoidable impurities.

[0038] The method for producing yield strength 180Mpa hot-dip galvanized baking hardening steel, its steps:

[0039] 1) Rough rolling: rough rolling at 1080°C;

[0040] 2) Finish rolling: the finish rolling temperature is controlled at 920°C;

[0041] 3) Coiling: coiling at 720°C;

[0042] 4) cold rolling: control the total reduction rate to carry out cold rolling under the condition of 78%;

[0043] 5) Continuous annealing: continuous annealing at 810°C;

[0044] 6) Cooling: Control the cooling rate at 38°C / s;

[0045] 7) Carry out finishing and set aside.

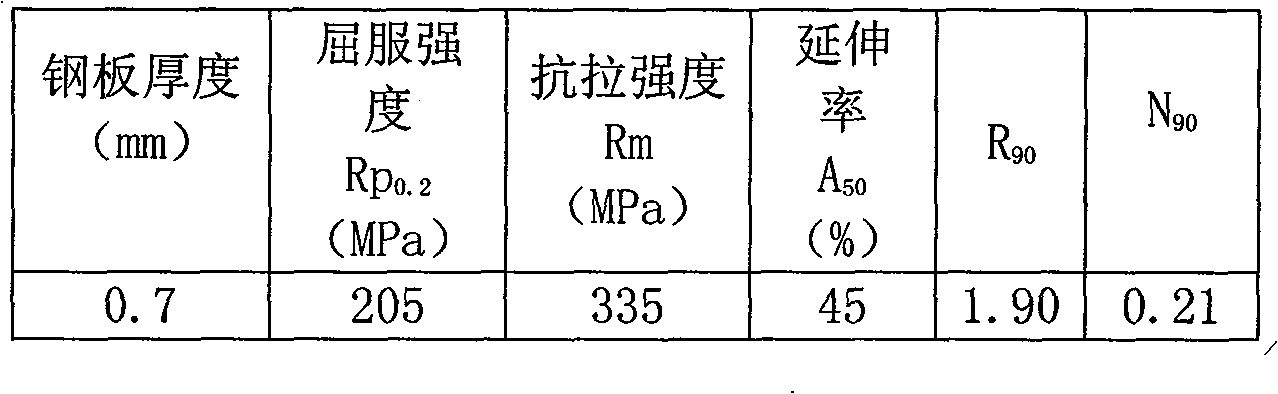

Embodiment 3

[0047] The test steel is the steel for the outer panels of the left and right front doors of automobiles:

[0048] Yield strength 180Mpa hot-dip galvanized bake-hardening steel, its chemical composition and weight percentage are: C: 0.0038, Si: 0.050, Mn: 0.28, P: 0.020, Nb: 0.011, Ti: 0.0042, ALs: 0.07, S< 0.015, N: 0.0028, and the rest are Fe and unavoidable impurities.

[0049] The method for producing yield strength 180Mpa hot-dip galvanized baking hardening steel, its steps:

[0050] 1) Rough rolling: rough rolling at 1085°C;

[0051] 2) Finish rolling: the finish rolling temperature is controlled at 910°C;

[0052] 3) Coiling: coiling at 710°C;

[0053] 4) cold rolling: control the total reduction ratio to carry out cold rolling under the condition of 80%;

[0054] 5) Continuous annealing: continuous annealing at 850°C;

[0055] 6) Cooling: Control the cooling rate at 43°C / s;

[0056] 7) Carry out finishing and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com