Optical recording medium, manufacturing method for optical recording medium, information recording/reproducing method and information recording/reproducing device

a manufacturing method and optical recording technology, applied in the field of optical recording medium, information recording/reproducing method, information recording/reproducing device, etc., can solve the problems of affecting the recording quality, so as to reduce the interference between the beams and prevent the back focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

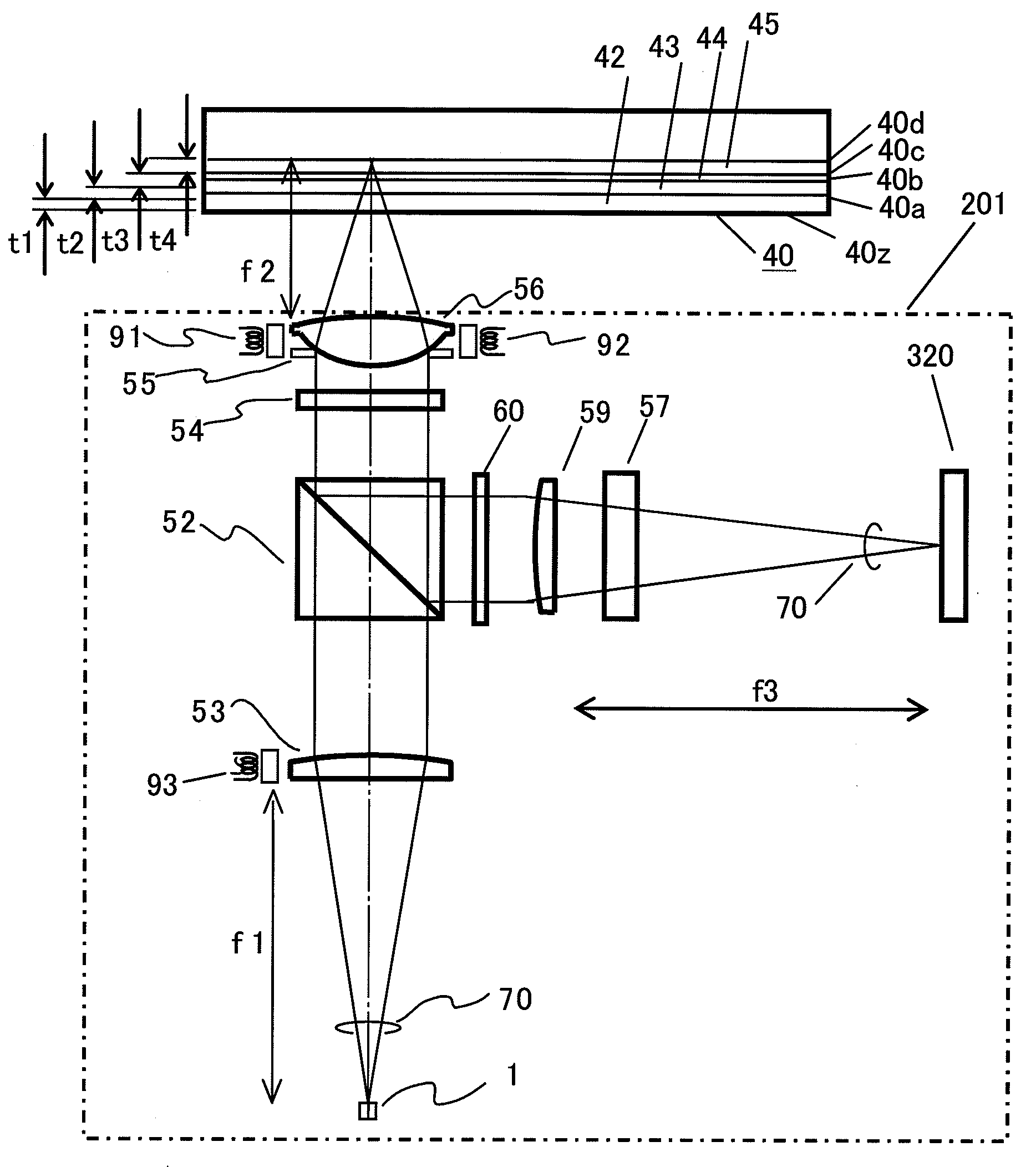

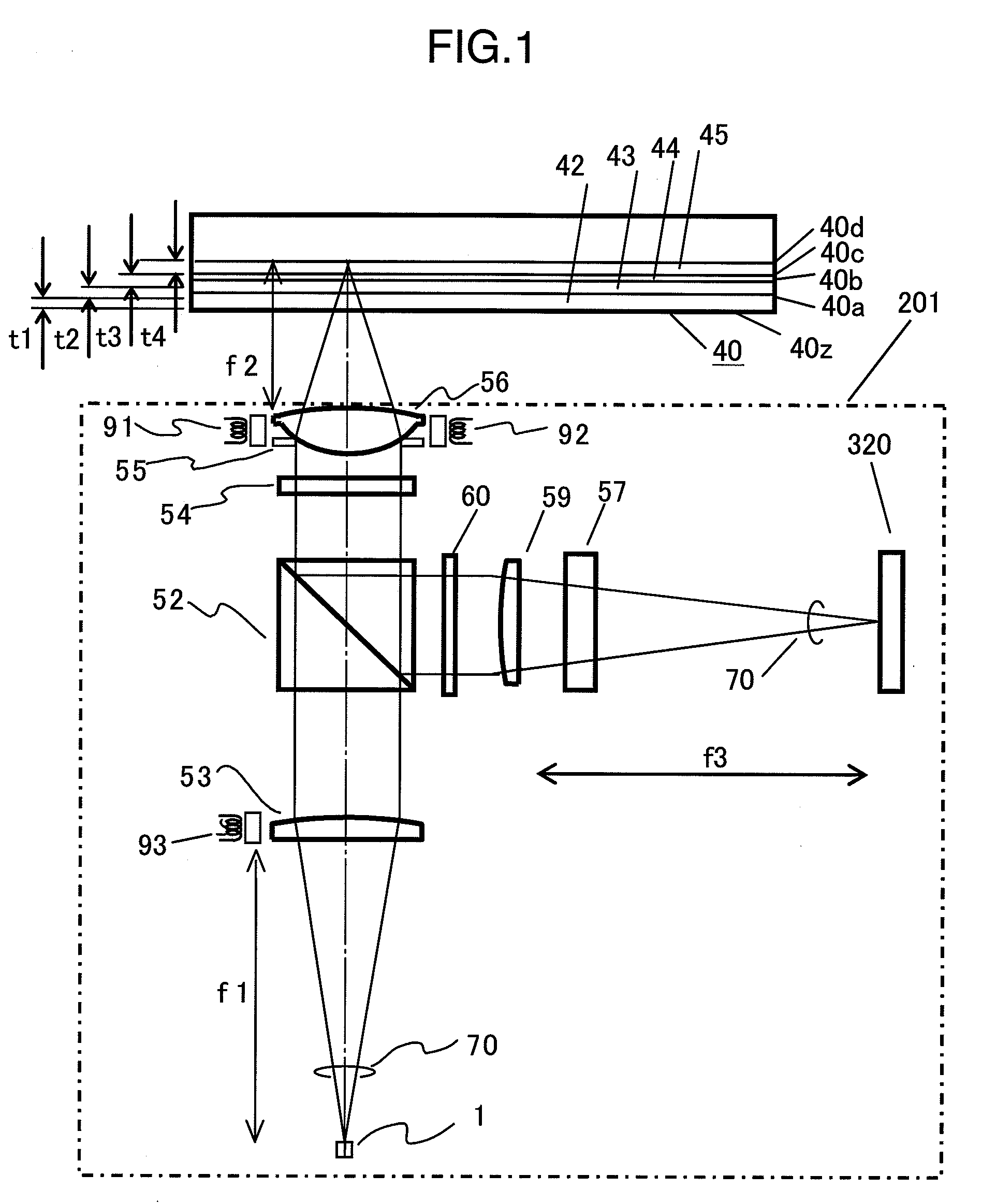

[0031]An embodiment of the present invention will be below described with reference to FIG. 1 and FIG. 2.

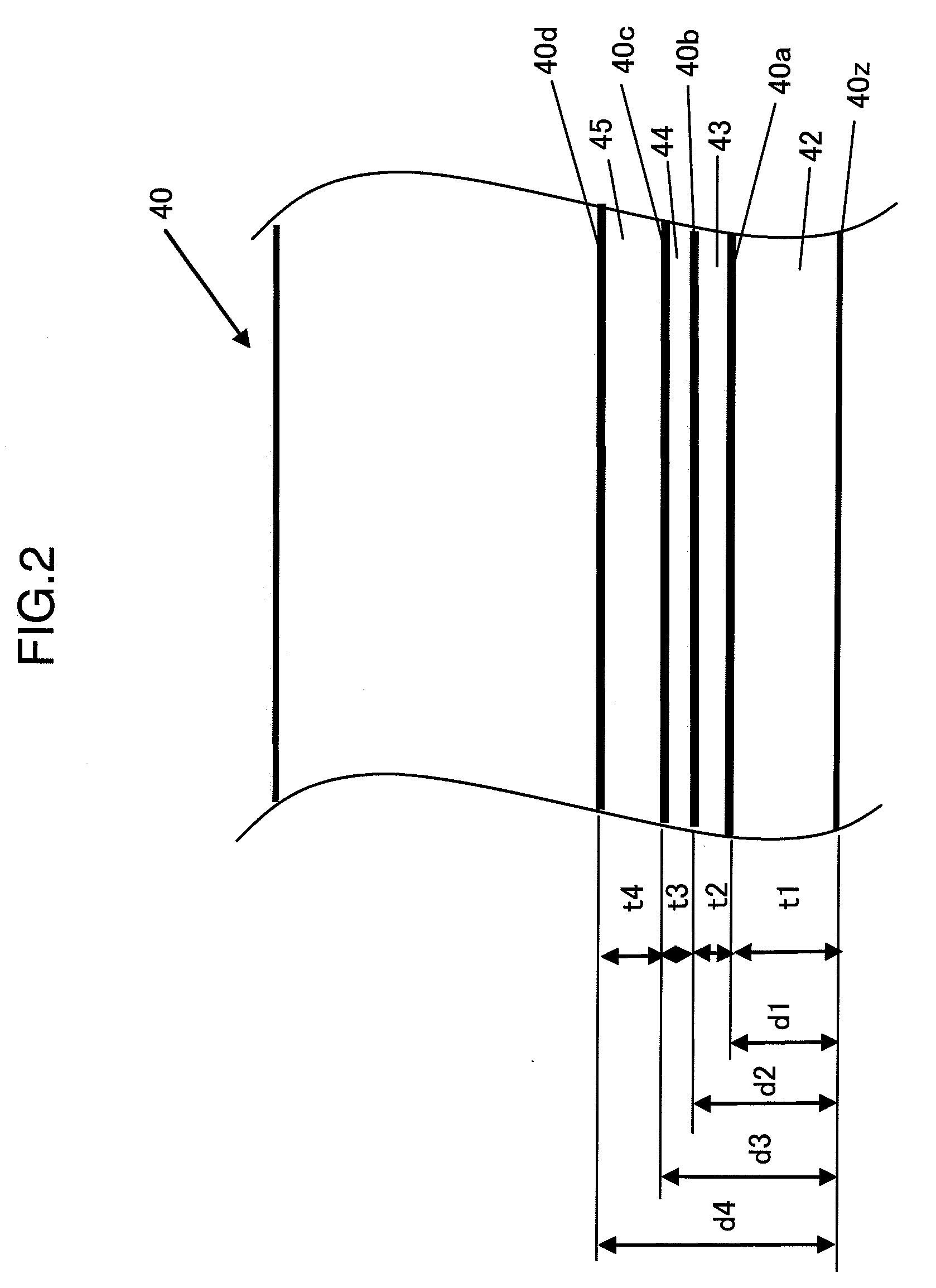

[0032]FIG. 1 shows a configuration of an optical information device according to the present invention. An optical pickup head unit 201 (or an optical pickup) irradiates an optical recording medium 40 with a blue laser beam having a wavelength λ of 405 nm or so to thereby reproduce a signal recorded in the optical recording medium 40. The optical recording medium 40 is formed with, as an example, four information recording surfaces—first to fourth information recording surfaces 40a, 40b, 40c and 40d in order from the face of the optical recording medium 40, as shown in FIG. 2. The optical recording medium 40 is also formed with a cover layer 42, a first intermediate layer 43, a second intermediate layer 44 and a third intermediate layer 45. The thickness of the cover layer 42 (substrate from a face 40z to the first information recording surface 40a) is t1; the thickness of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness t1 | aaaaa | aaaaa |

| thickness t1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com