Hall Effect-Based Real-Time Lubrication Monitoring System Modes of Operation and Use Thereof

a real-time lubrication monitoring and monitoring system technology, applied in engine lubrication, liquid/fluent solid measurement, electrical/magnetic means, etc., can solve problems such as difficult to protect a sensor or sensor array from degradation, and often in excess of 150°C

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

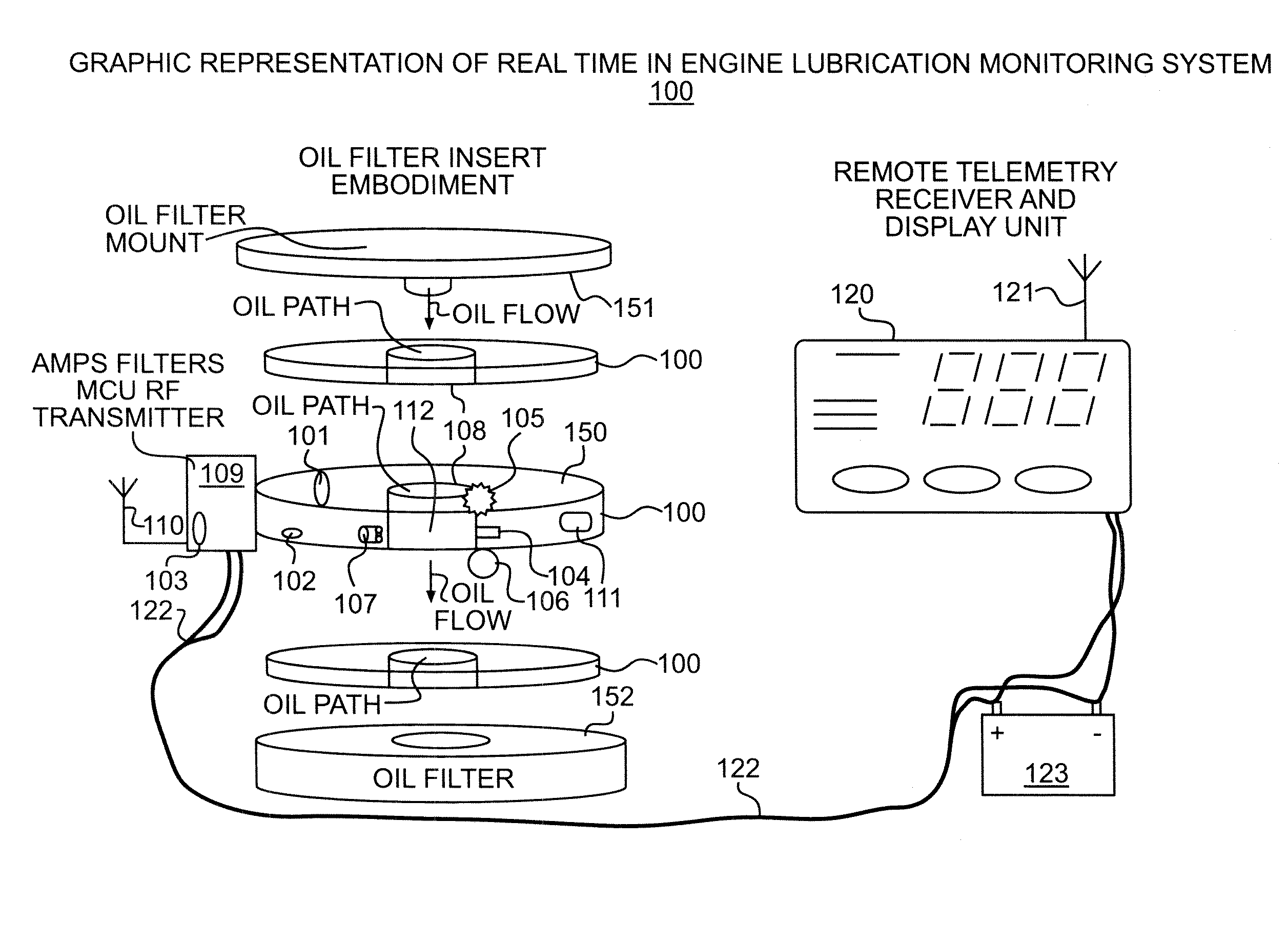

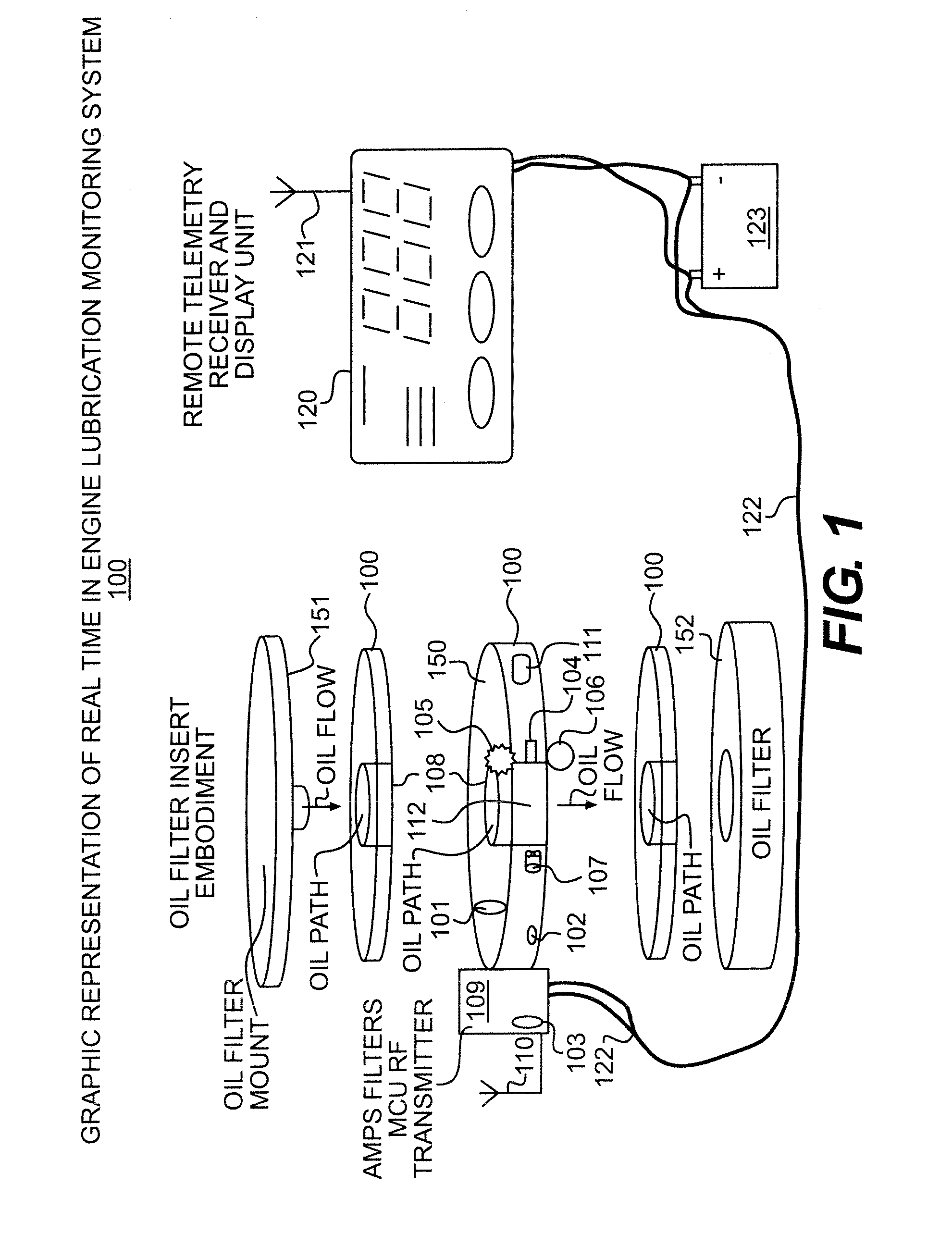

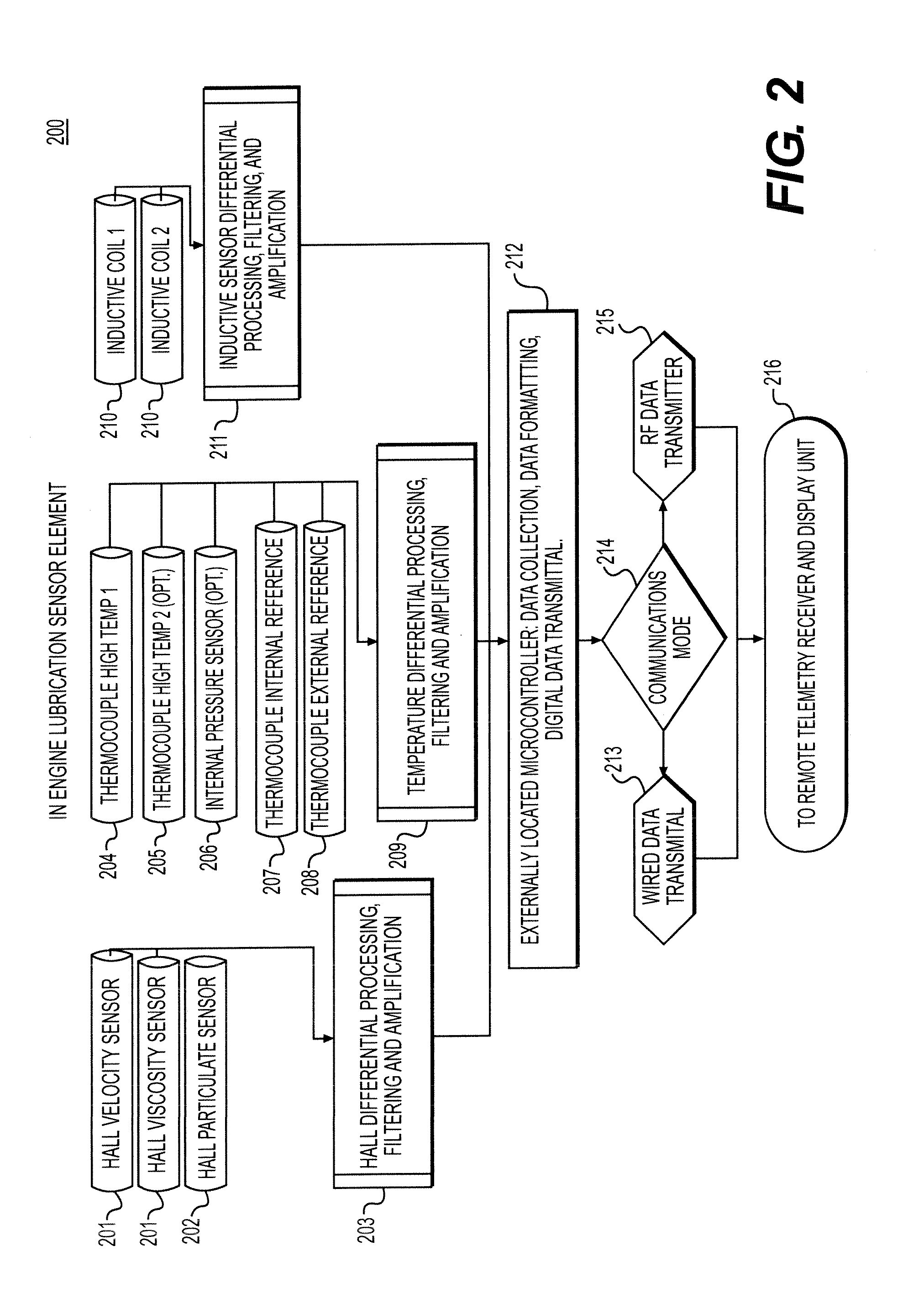

[0015]The exemplary embodiment shown in FIG. 1 comprises two main physical parts—the sensor element or assembly 100 and the display unit 120. Both parts comprise mechanical units and software / firmware elements working in concert to collect, process, and display the required data.

[0016]The sensor element 100 comprises several physical units and is designed to be installed within the associated engine or related mechanical device, which requires constant fluidic-based lubrication. According to one embodiment of the invention, the sensor element 100 comprises an overall form factor of that of a disc-shaped insert placed within the engine block and the oil filter. The sensor assembly 100 comprises a series of stacked discs 150, which allow for the physical manufacture of the complete assembly. One side of the sensor assembly 100 is designed to be mounted on the engine block 151 and provides inlet and outlet flow paths substantially similar to those already present in the attached oil fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com