Compressor stabilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

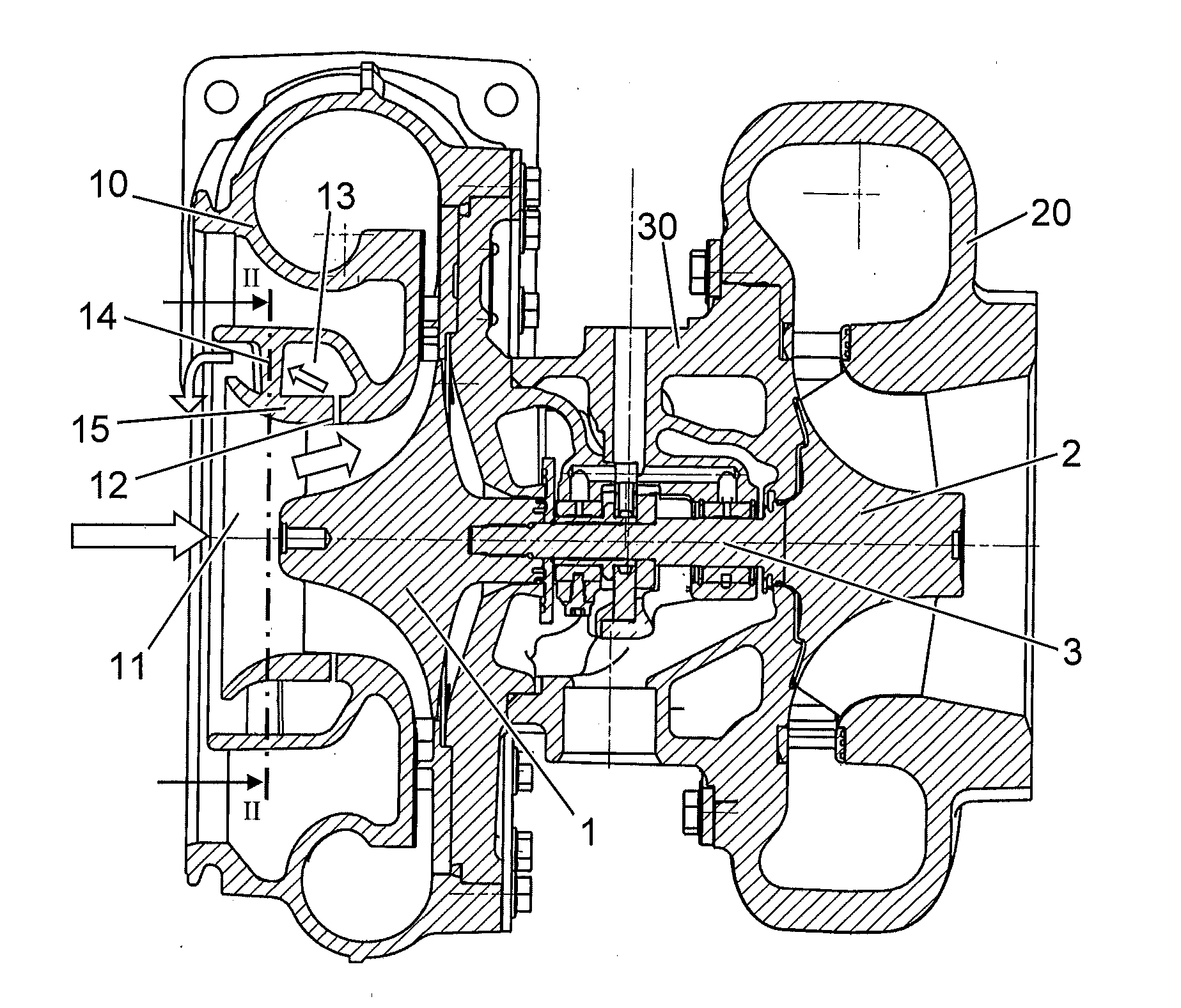

[0013]Vibration-reducing measures are disclosed for a compressor having a circulation chamber which is delimited from the main flow.

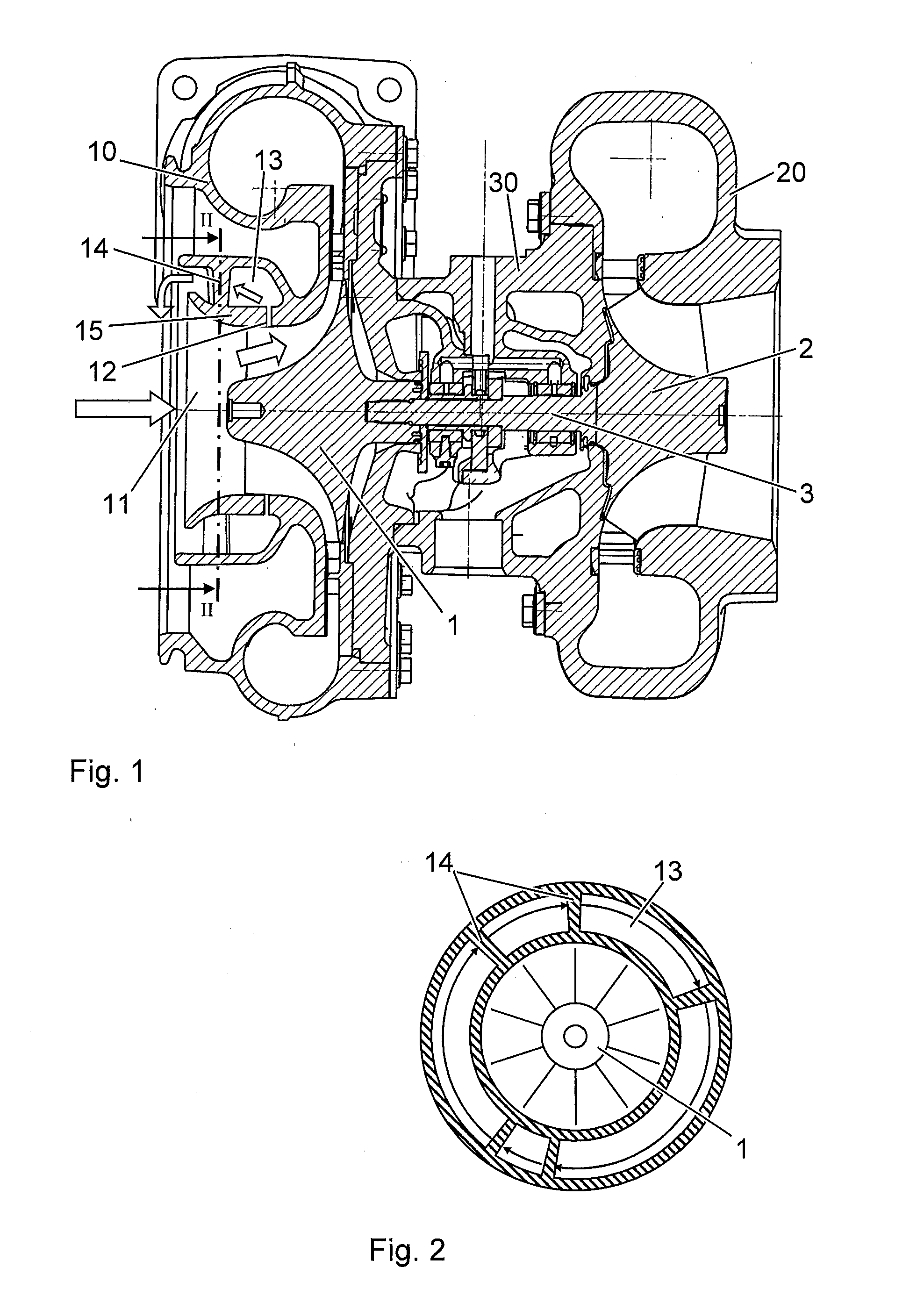

[0014]According to the exemplary embodiments, the struts which support a contoured wall are arranged spaced apart from one another to different extents in a circumferential direction.

[0015]A uniform distribution of support ribs can lead to formation of exemplary excitation orders in the vibration excitation, with the excitation orders being directly dependent on the number of support ribs. With a non-uniform distribution, the available excitation energy can be distributed between different excitation orders. The excitation per excitation order can therefore be reduced, and specific resonances can be targeted and avoided (e.g., suppressed). A non-uniform distribution of the support ribs can therefore lead to a reduced excitation of the rotor blade vibration.

[0016]The non-uniform distribution of the support ribs can have an effect on distribution of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com